Atomizing generator and special high-pressure atomizing generating device used for oil-gas field production increase

An atomization generator and high-pressure atomization technology, which is applied in the direction of mining fluid, measurement, wellbore/well components, etc., can solve the problem that chemical additives are difficult to play, reduce the effect of chemical additives, and cannot be sprayed by chemical additives. problems such as chemicalization, to achieve the effect of improving oil and gas recovery, temperature resistance, light weight, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

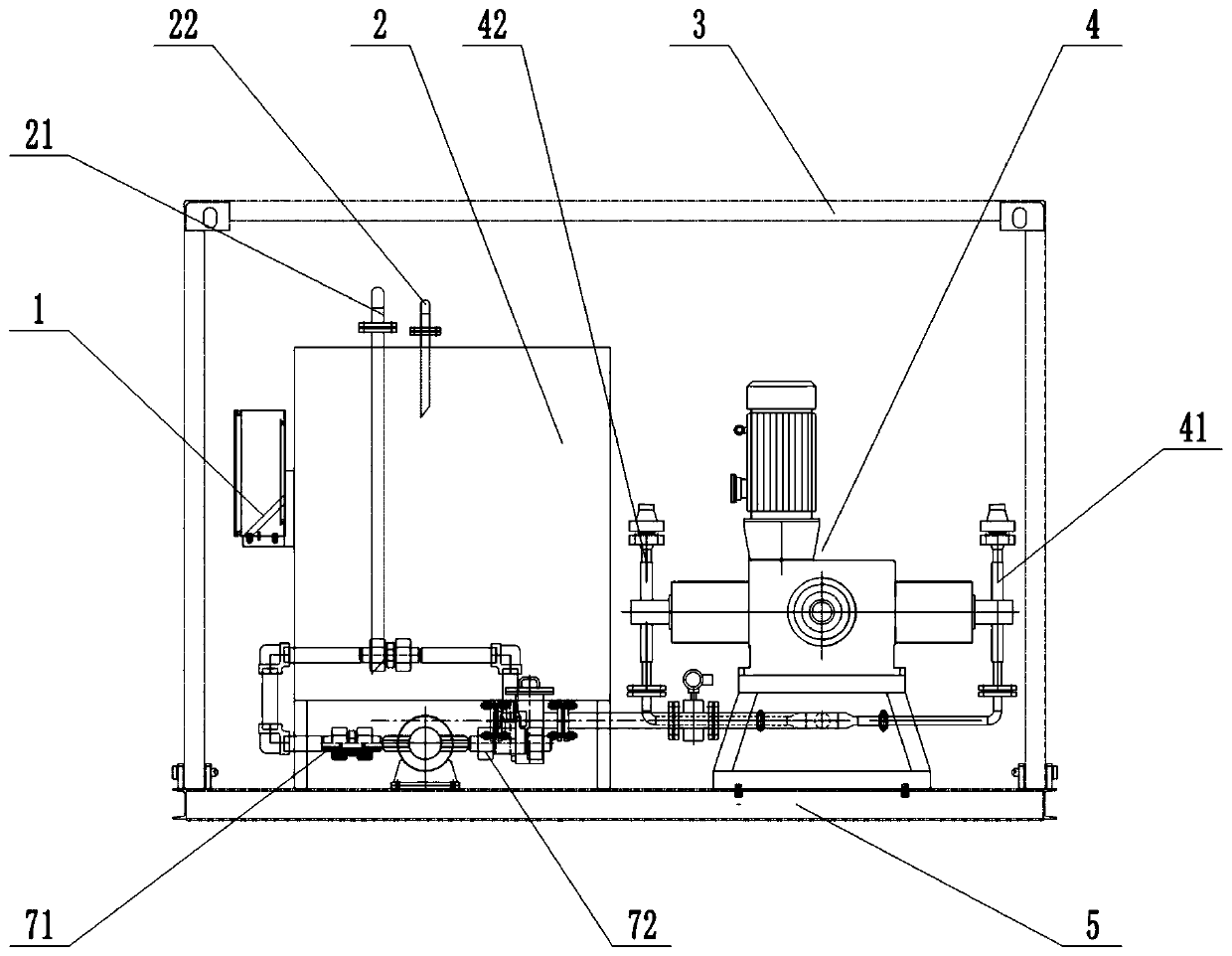

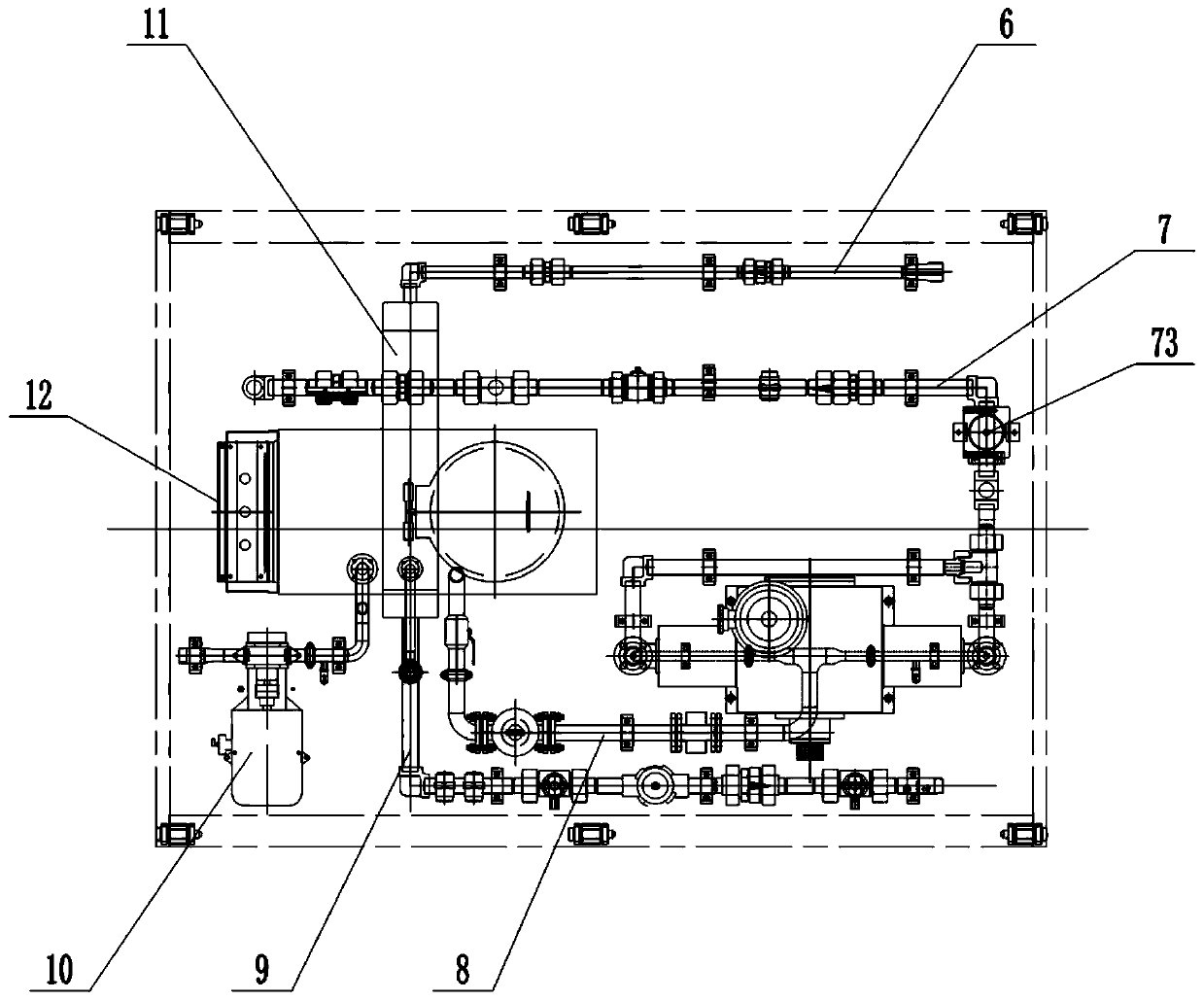

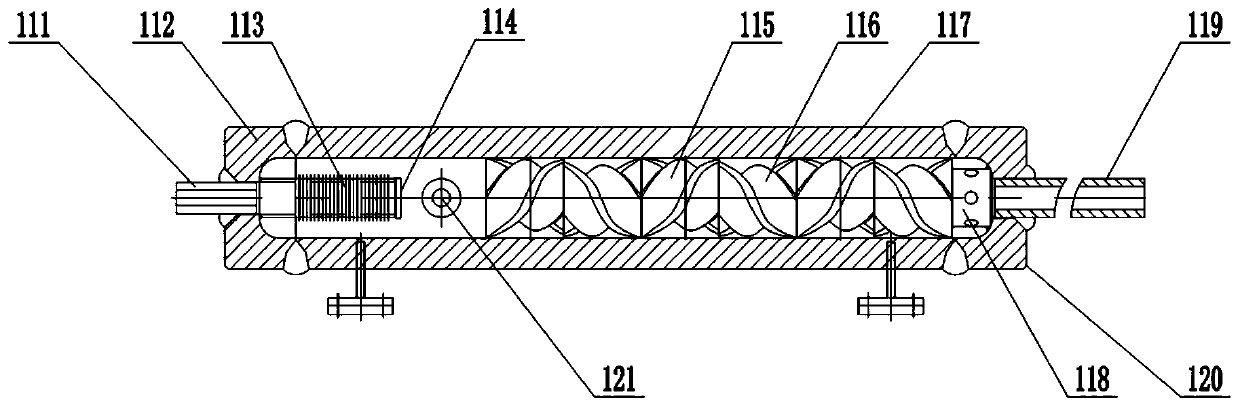

[0034]An atomization generator, comprising an atomization generator cylinder 117, an air inlet head 112, a discharge head 120, a gas distribution pipe 113, a liquid inlet pipe 121, an air inlet pipe 120 and a stirring block, the atomization generator The two ends of the cylinder 117 are respectively equipped with an air inlet head 112 and an outlet head 120, the air inlet pipe 111 is arranged at the front end of the air inlet head 112, and one end of the air inlet pipe 111 is connected to the high-pressure air inlet pipeline 6 The air inlet pipe 111 is provided with an air distribution pipe 113 at the other end of the air inlet head 112. The air distribution pipe 113 is a pipe with several small holes on the circumference, and the end of the air distribution pipe 113 is provided with a blocking plate 114. The discharge head 120 is provided with a discharge pipe 119, the inside of the atomizer cylinder 117 is provided with a rotatable stirring block, and one end of the atomizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com