Solid anchor rod capable of being grouted

A grouting and bolting technology, which is used in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problem that the grouting pressure is low, the grouting effect cannot be achieved, the effect of anchoring and grouting is affected, and the hollow grouting bolt High cost and other problems, to achieve the effect of improving support efficiency, improving roadway support efficiency, and improving anchorage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

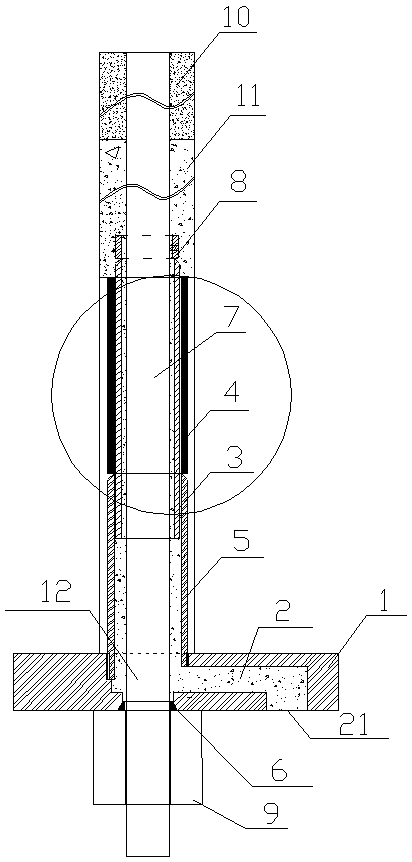

[0041] see figure 1 A groutable solid anchor rod comprises a solid anchor rod and an auxiliary grouting sealing mechanism.

[0042] The solid anchor rod includes a rod body 7, a tray and an anchor 9; the rod body 7 is a ribbed steel bar, and a limit stop ring 8 and a limit stop ring 8 are fixed on one end of the rod body 7 at a distance of 0.6-0.8 meters from the leaking end. structure see Figure 7 . The tray is a grouting backing plate 1 .

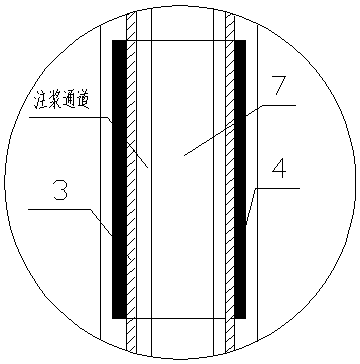

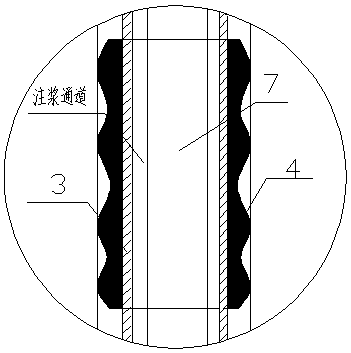

[0043] see Figure 4 , the auxiliary grouting sealing mechanism includes a grouting conduit 5 , a thin-walled steel pipe 3 , a sealing pipe 4 and a sealing ring 6 . see Figure 5 , the grouting backing plate 1 is provided with a vertically penetrating anchor hole 12; one end of the anchor hole 12 is a sealing port, and the sealing port is a conical hole with a large outside and a small inside, and a sealing ring 6 is installed on the sealing port, and the sealing ring 6 is a tapered sealing ring. The other end opening of the ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com