Electric proportional control hydraulic multi-way reversing valve and control method thereof

A multi-way reversing valve, electric proportional technology, applied in multi-way valve, valve details, valve device and other directions, can solve the problems of complex control algorithm, difficult to popularize and apply in a large area, high implementation cost, and achieve high control accuracy and structure. Simple, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

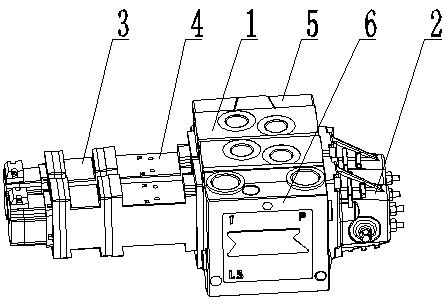

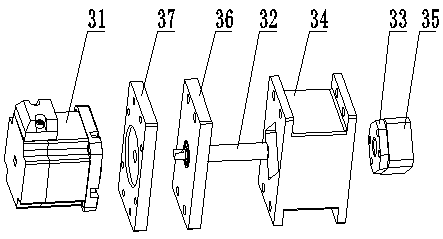

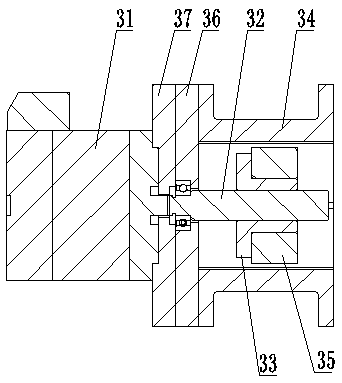

[0049] In order to make the technical objectives, technical solutions and beneficial effects of the present invention clearer, the following in conjunction with the attached Figure 1-11 The technical scheme of the present invention is further described with specific embodiments. In the following embodiments, the direction in which the slide valve spool moves toward the drive unit is left, and the direction in which the slide valve spool moves away from the drive unit is right. .

[0050] An embodiment of an electric proportional control hydraulic multi-way reversing valve:

[0051] An electric proportional control hydraulic multi-way reversing valve includes a valve body 11 with multiple reversing units, each reversing unit includes a main valve core 12, and one end of each main valve core 12 is equipped with a group of electric proportional valves. Hydraulic control device, the other end of the main spool 12 can optionally be equipped with a manual control device 2, and eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com