Cooling device for reducing temperature of finished carbon black

A technology of cooling device and carbon black, applied in the field of cooling device and cooling device for reducing the temperature of finished carbon black, can solve problems such as scorching, carbon black ignition, enterprise loss, etc., achieve timely packaging, use less quantity, and avoid excessive time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

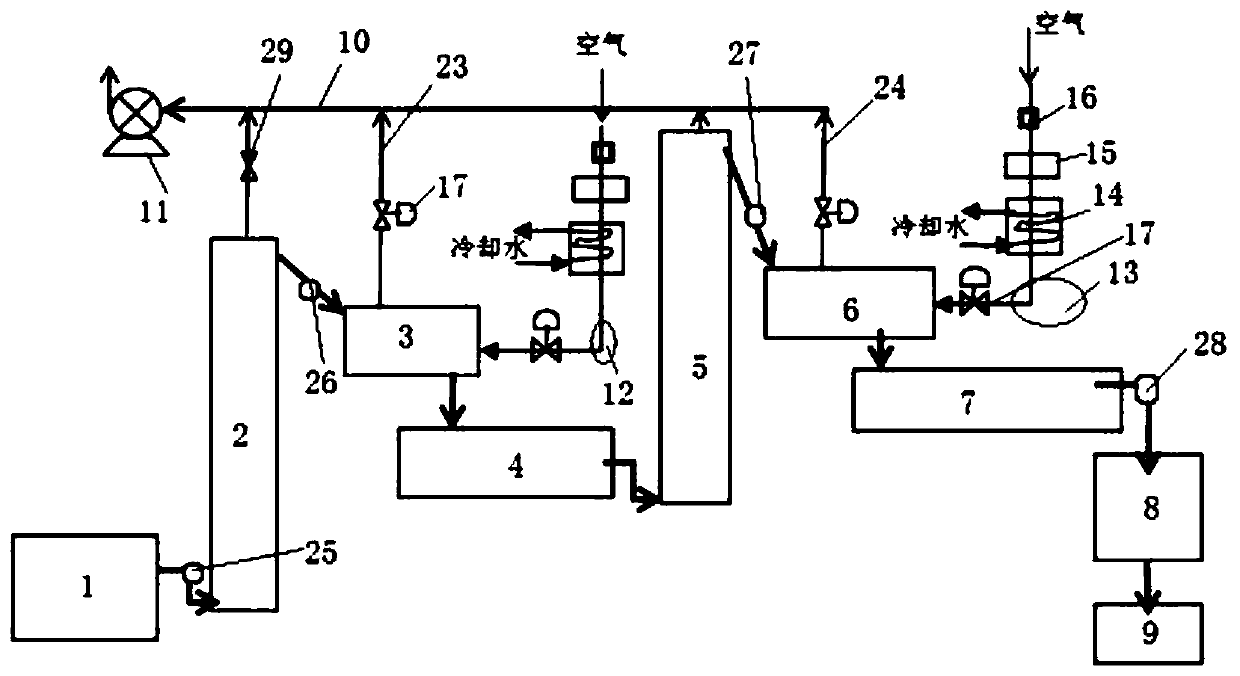

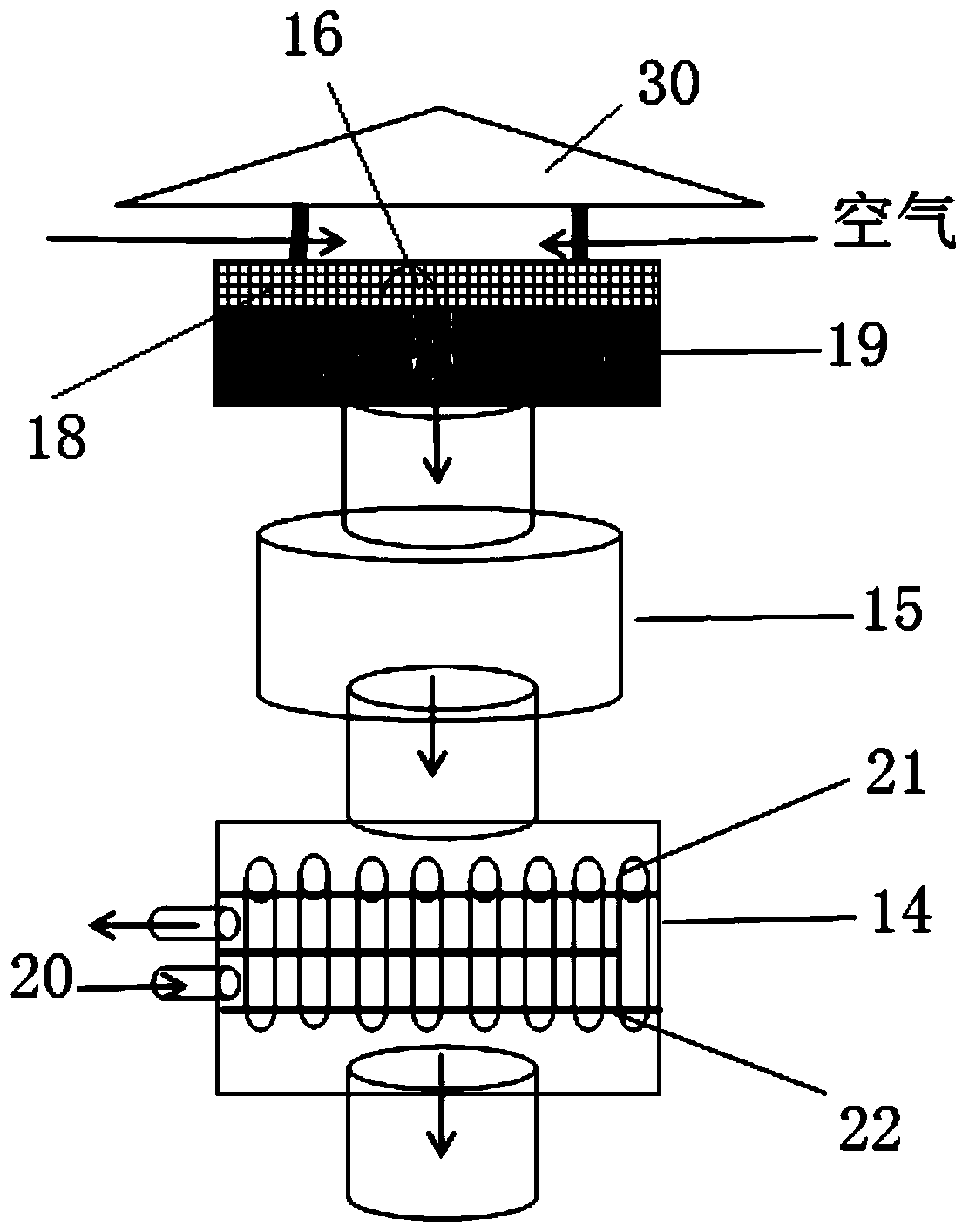

[0020] Such as Figure 1-2 Shown, device of the present invention is realized in this way, a kind of finished product carbon black flow process production device mainly comprises carbon black drier 1, the first lifter 2, screening machine 3,502 transport twisted cage 4, the second lifter 5, The rotary iron remover 6, 504 transports the twisted cage 7, the carbon black storage tank 8, the packaging machine 9, the equipment dust suction fan 11 and the dust suction main pipe 10; it is characterized in that: the carbon black dryer 1 is connected to the first hoist 2 through a pipeline, The first hoist 2 is connected to the screening machine 3 through the pipeline, and the screening machine 3 is connected to the 502 conveying cage 4 through the pipeline, and the 502 conveying cage 4 is connected to the second hoist 5 through the pipeline, and the second hoist 5 is connected to the rotary iron separator 6 through the pipeline , the rotary iron remover 6 is connected to the pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com