Capacitor voltage reduction cascade type multi-path intelligent sub-control contactor

A capacitor step-down, capacitor technology, applied in circuits, relays, AC motor control and other directions, can solve the problems of complex circuits, large space occupation, and high cost of single-phase motor group control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

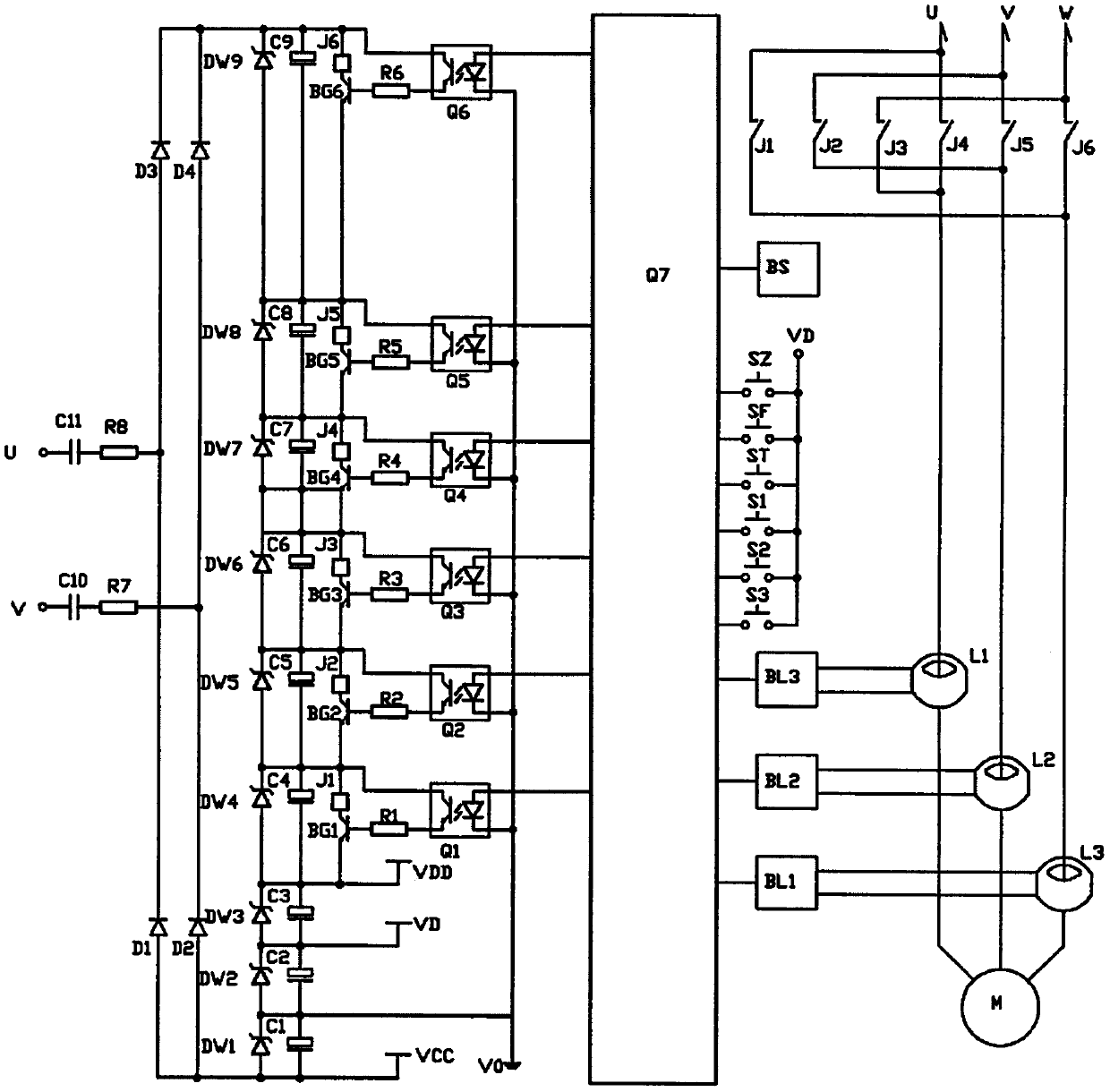

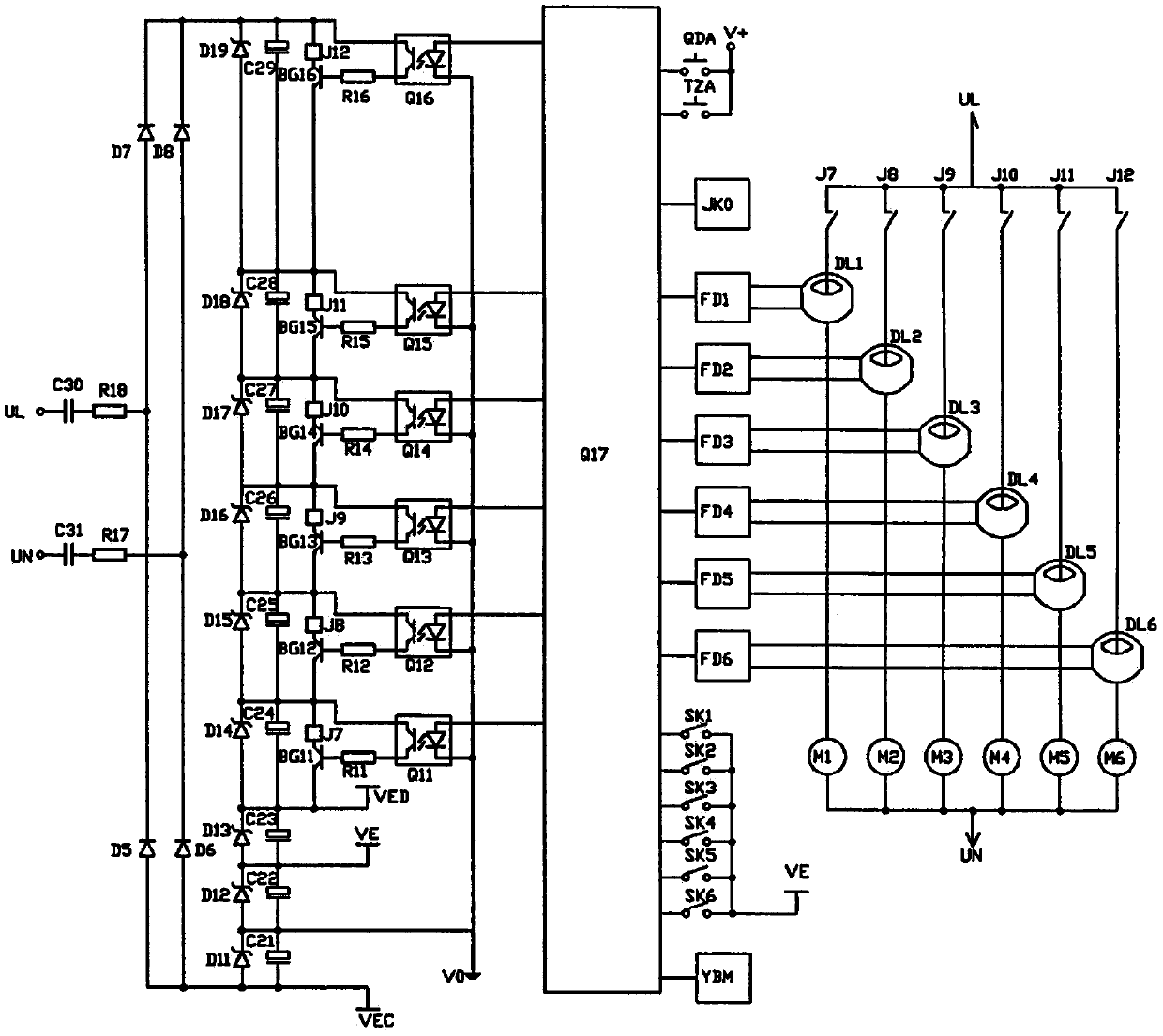

[0009] figure 1It is a capacitor step-down cascading multi-channel intelligent sub-control contactor. The working principle is to step down and rectify the capacitor and then connect it in series with a multi-channel regulated power supply circuit and a relay, and then control it respectively by multiple optocoupler isolators. Multiple relays can reduce the current through the capacitor step-down circuit by multiples. Use 3 high-current single-contact relays as a group of relays to pull in simultaneously to replace the three-phase contacts of the three-phase AC contactor, or use 2 groups Relays or multiple sets of relays pull in at the same time to increase power instead of AC contactors to control motors, or separately control 2 sets of relays or 4 sets of relays to pull in to realize AC contactors to control multiple motors or the positive and negative rotation of motors. It can also be controlled by control circuits or The single-chip microcomputer respectively controls mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com