Oilseed rape precision direct seeding machine based on crawler-type combined harvesting power platform

A crawler type, direct seeding machine technology, applied in harvesters, tillage machines, agricultural machinery, etc., can solve problems affecting the efficiency and quality of rapeseed sowing operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

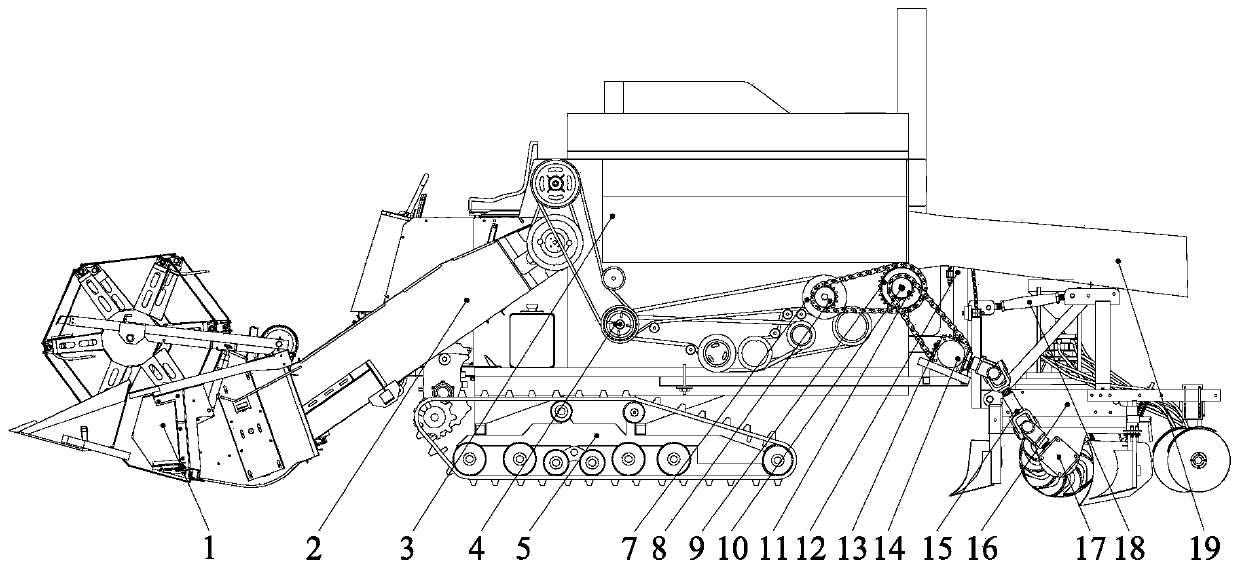

[0021] Such as figure 1 The rape precision direct seeding machine based on the crawler-type combined harvesting power platform shown includes a harvesting system, a suspension lifting device 12 and a plowing and sowing system 16, wherein the harvesting system includes a straw harvesting table 1, a conveying chain rake 2, and a threshing and cleaning device 3. Grass outlet 19 and harvesting drive system. Field stubble and floating grass are picked up and cut by the straw harvesting platform 1, and then sent to the tail of the combined harvesting system under the conveying action of the conveying channel composed of the conveying chain harrow 2 and the threshing and cleaning device 3, and the rotary tillage and sowing operation is completed in the plowing and sowing system 16 Afterwards, it is discharged by the grass outlet 19 to compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com