Remote automatic start-stop system for pulverizer and start-stop method thereof

An automatic start-stop, mill technology, used in grain processing and other directions, can solve the problem of equipment not having self-judgment to eliminate the impact, affecting the construction progress, affecting the service life of the equipment, etc., to achieve flexible and diverse processing methods and avoid equipment damage. phenomenon, the effect of avoiding miscommunication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

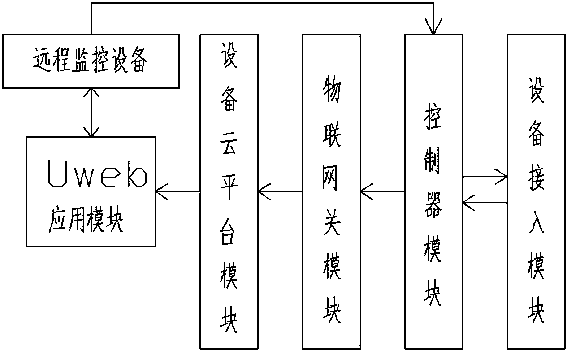

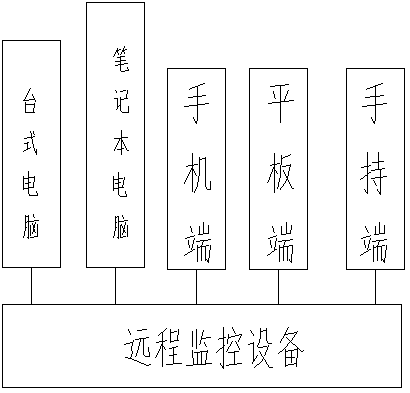

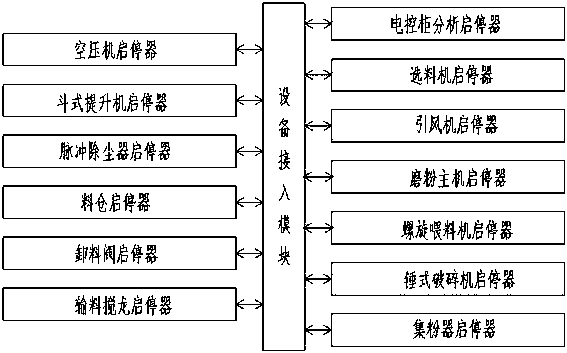

[0015] Such as figure 1 , 2 . As shown in 3, a remote automatic start-stop system for a pulverizer includes an equipment access module, the output end of the equipment access module is connected to the input end of the controller module, and the controller module and the Internet of Things gateway module The IoT gateway module is connected to the device cloud platform module, the device cloud platform module is connected to the Uweb application module, the Uweb application module is connected to the networked remote monitoring device, and the remote monitoring device is connected to the controller module through the Internet. The output end of the controller module is connected to the input end of the equipment access module. The equipment access module includes an air compressor start-stop device, a bucket elevator start-stop device, a pulse dust collector start-stop device, a silo start-stop device, a discharge valve start-stop device, and a clinker auger start-stop device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com