Multi-track numerical control type machining equipment for steel structure machining and machining process

A technology of processing equipment and processing technology, which is applied in the field of steel processing, can solve the problems of affecting efficiency, inconvenient processing, heavy weight, etc., and achieve the effects of improving processing efficiency, reducing production space and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments.

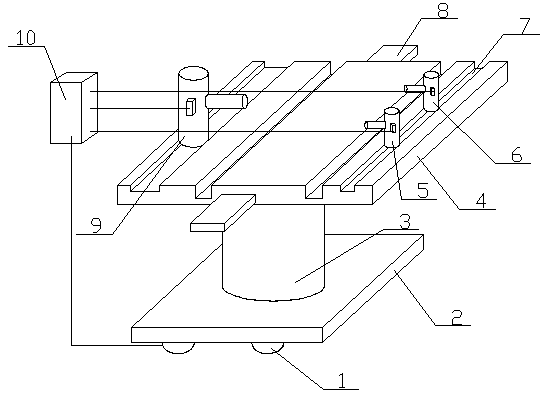

[0014] A multi-track numerical control processing equipment for steel structure processing is characterized in that it includes an operating table 4, a support 3) and a base 2, wherein the upper surface of the operating table 4 is provided with a plurality of chute 7, the The widths of the chutes 7 are all different, and a plurality of forging equipment 5, bending equipment 6 and cutting equipment 9 are slidably arranged in the corresponding chute 7, and the bending equipment 7 and the cutting equipment 9 are all provided with electric controllers. The electric signal is connected with the controller 10 provided at the remote end by wires; the front and rear sides of the console 4 are provided with connecting blocks 8; the bracket 3) is installed on the bottom of the console 4, and the base 2 is installed on the bracket 3) At the bottom, a universal wheel 1 is arranged unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com