A precision fine-tuning device for on-machine measurement function integration

A fine-tuning device and precise technology, applied in the detection field, can solve problems such as small adjustment range, low structural rigidity of the probe adjustment device, and low displacement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

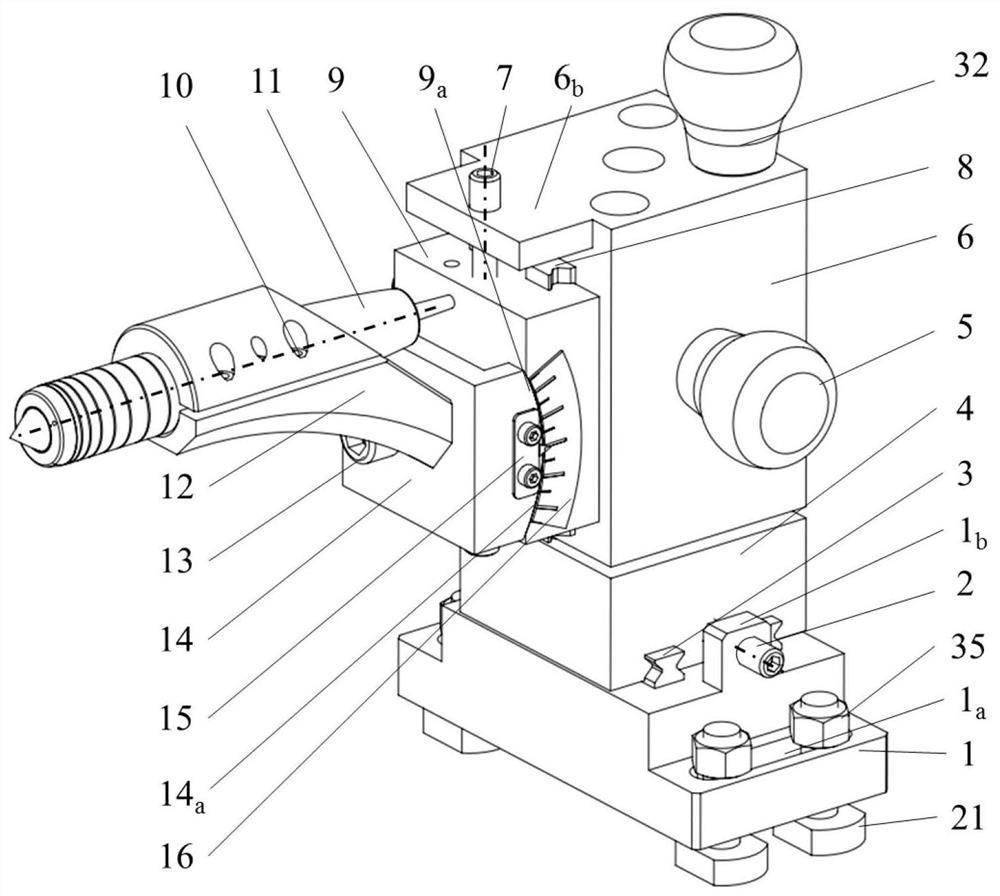

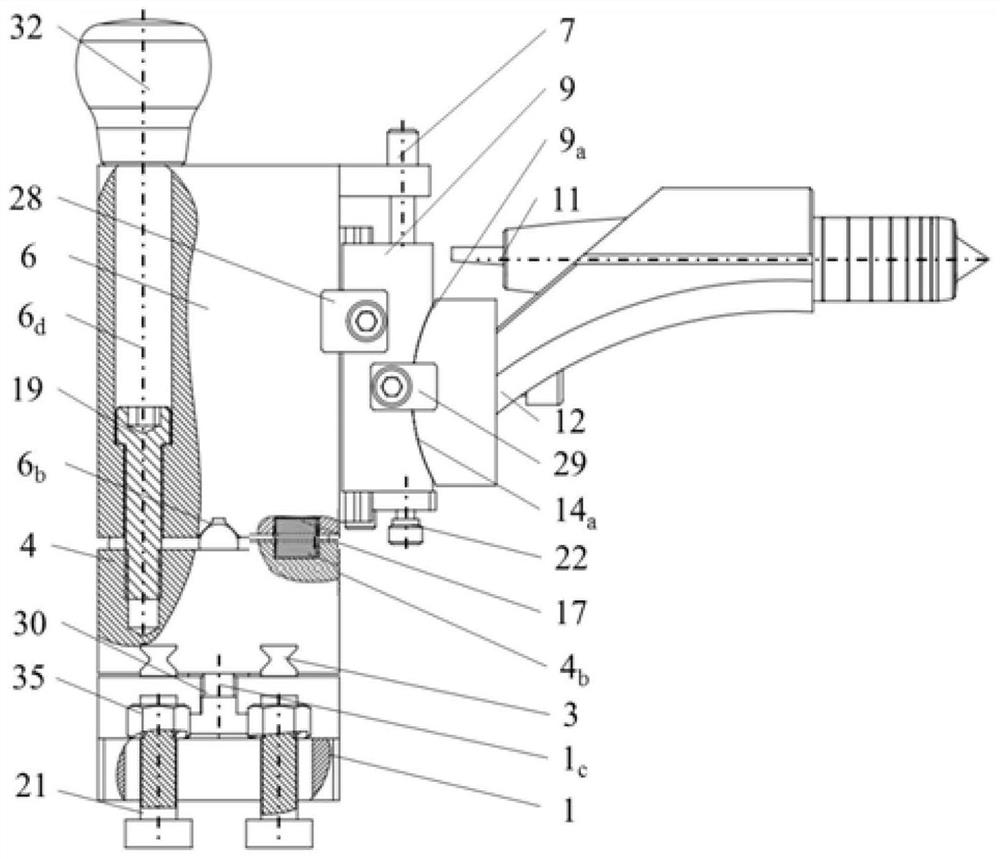

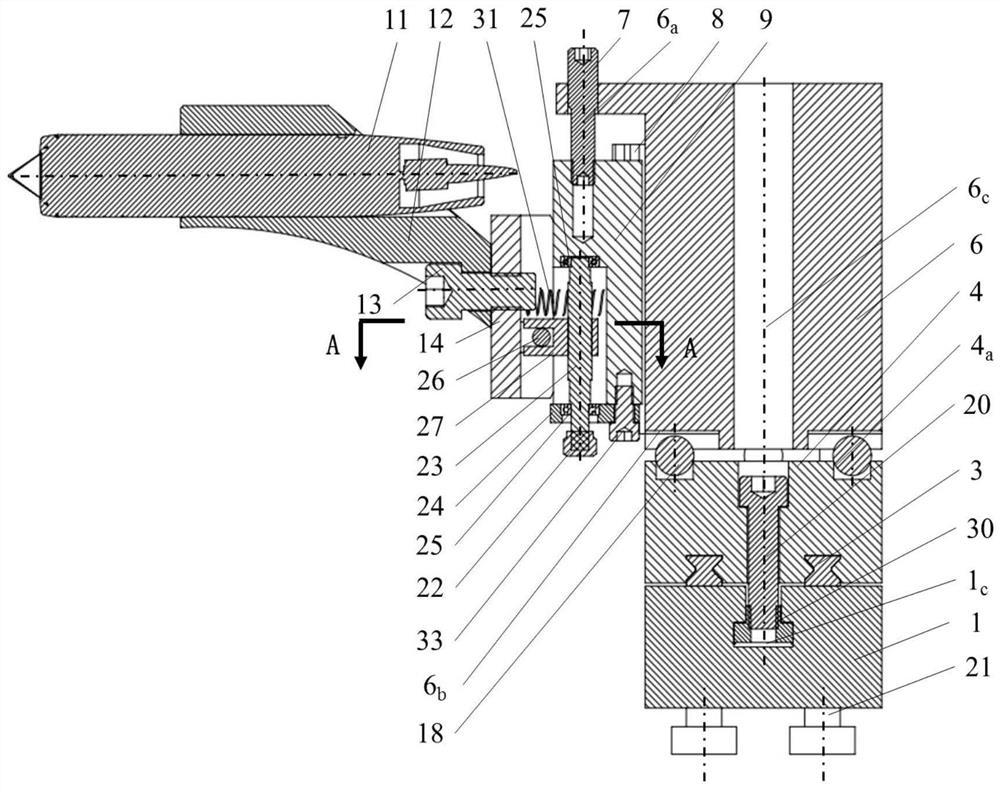

[0014] The specific embodiment of the present invention will be described in detail in conjunction with the accompanying drawings.

[0015] A precision fine-tuning device for the integration of on-machine measurement functions, its working principle: a long hole 1 is processed on the base 1 a , the T-bolt installed in the T-slot of the machine table passes through the long hole 1 a Fix the base 1 and the machine table with the hex nut 35; slide the X-direction sliding seat 4 on the X-direction sliding guide rail 3 to a suitable position, and the rough adjustment of the sensor measuring head 11 in the X direction can be completed. After the rough adjustment is completed, turn the X direction fine adjustment screw 2 to realize the fine adjustment of the sensor probe 11 in the X direction. After the adjustment is completed, use the set bolt 20 to cooperate with the T-shaped slot cThe tightening T-nut 30 in the middle completes locking. In the same way, the Y-direction sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com