A straight line is easy to tear the aluminum -plated nylon film and its preparation method

A nylon film, nylon technology, used in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of difficult to meet market demand, few types, etc., achieve good linear tear performance, extended shelf life, excellent oxygen The effect of barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the linear easy-to-tear aluminized nylon film provided by the embodiment of the present invention comprises:

[0035] Step 1, basement membrane preparation:

[0036] ①Mix the components in layers A, B, and C respectively in proportion, and disperse evenly through a high-speed mixer;

[0037] ② Melt and co-extrude the homogeneously mixed raw materials in ① through three extruders, and cast the melt through a T-shaped die to a quenched cast sheet with a chilled roller with a surface temperature of 15-35°C;

[0038] ③Put the cast sheet in ② in a 40-75°C water tank for about 1-2 minutes of humidity-conditioning treatment. After the humidity-conditioning, the surface of the cast sheet is dried with an air knife to dry the residual moisture on the surface, and then stretched synchronously or distributedly. The stretching temperature is 130-205°C, and the stretching ratio is 2.5×2.5-3.5×3.5;

[0039] ④ The film obtained in ③ is subjected to heat set...

Embodiment 1

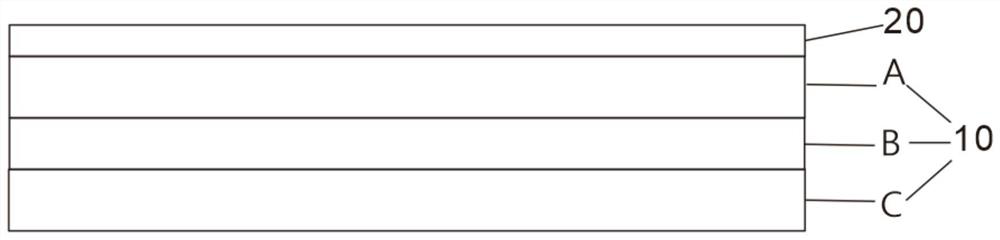

[0042] Such as figure 1 As shown, a linear easy-to-tear aluminum-coated nylon film, the thickness of the base film is 15 μm, the thickness of the A and C layers is 2 μm, and the thickness of the aluminum vapor-deposited layer is 40 nm.

[0043] In terms of mass percentage, layer A and layer C are both composed of 69.5% nylon 6, 30% special nylon composition and 0.5% anti-stick nylon masterbatch; layer B is composed of 70% nylon 6 and 30% special nylon composition;

[0044] The special nylon composition is composed of MXD6-PA66 copolymer, PA512, PA66 / PA6 copolymer and MXD6-g-MAH, and the content ratio is 6:4:3:1.

Embodiment 2

[0046] Such as figure 1 As shown, a linear easy-to-tear aluminized nylon film, the thickness of the base film is 15 μm, the thickness of the A and C layers is 3 μm, and the thickness of the aluminum vapor deposition layer is 100 nm.

[0047] In terms of mass percentage, layer A and layer C are composed of 79% nylon 6, 20% special nylon composition and 1% anti-stick nylon masterbatch; layer B is composed of 65% nylon 6 and 35% special nylon composition;

[0048] The special nylon composition is composed of MXD6-PA66 copolymer, PA612, MXD6 / PA6 copolymer and MXD6-g-MAH, and the content ratio is 7:3:3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| corona value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com