Gas generating agent for high burning rate micro gas generator and preparation method thereof

A technology of gas generator and gas generating agent, which is applied to offensive equipment, explosives, inorganic oxyhalide salt explosive compositions, etc., can solve the problems of slow burning speed and low gas production of MGG, and achieve increased gas production and good flame sensitivity. , the effect of increasing the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

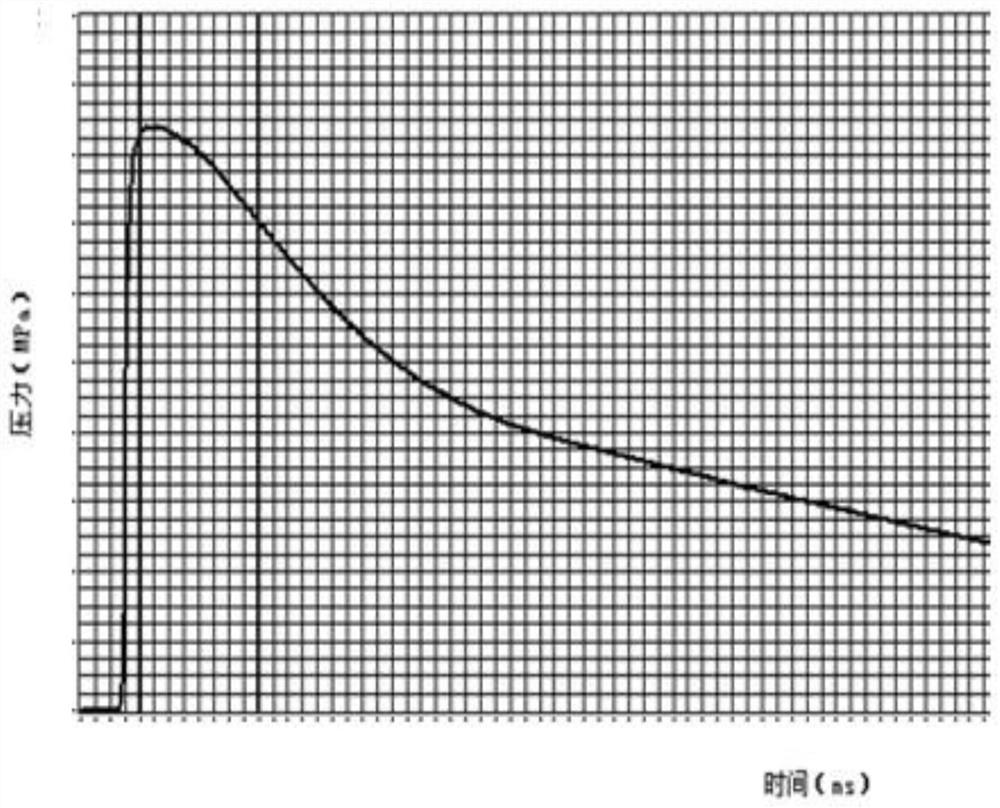

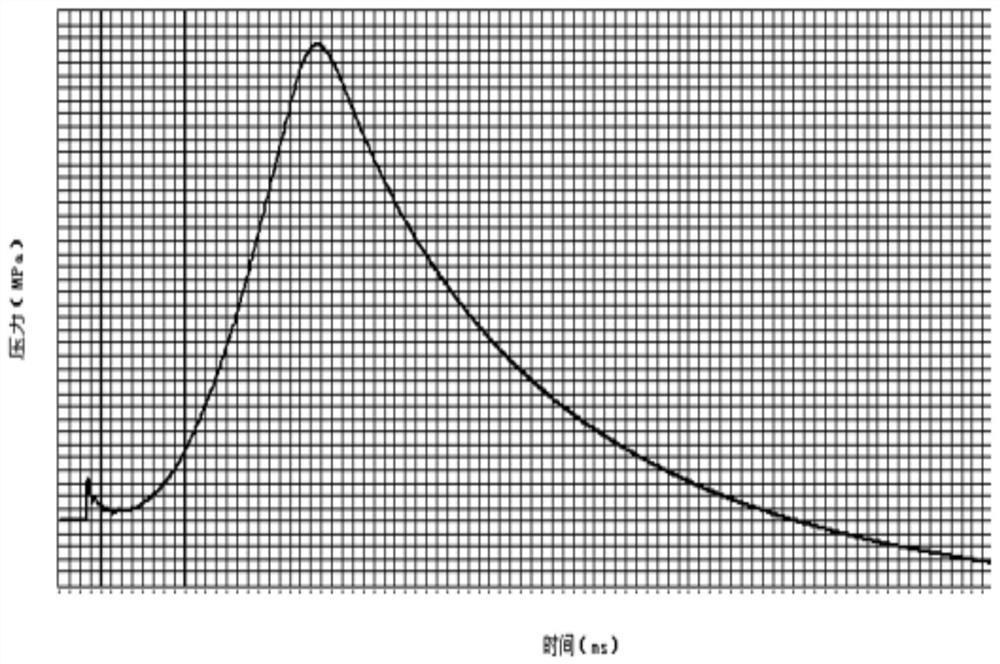

Image

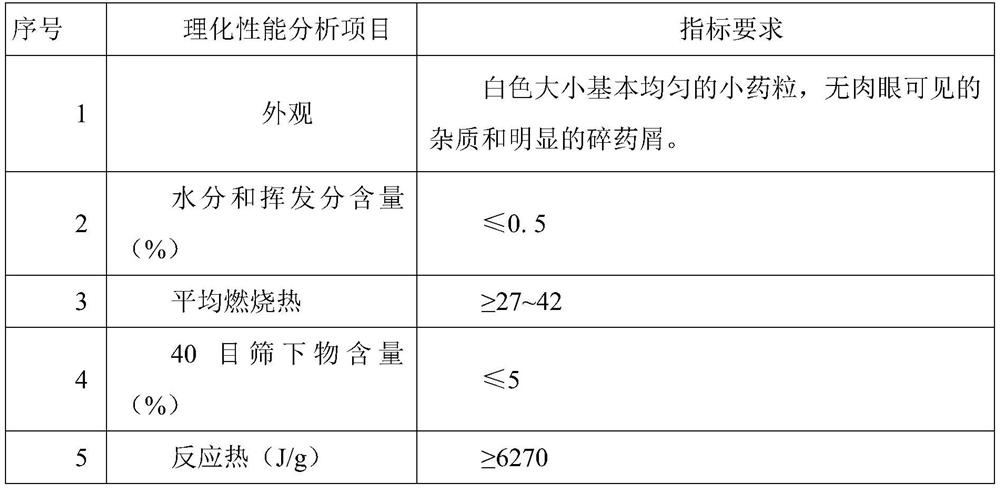

Examples

Embodiment 1

[0029] 1. Preparation of ammonium nitrate (AN) agent: AN raw materials are inspected and processed, crushed to 20-30 mesh by a crusher, dried and put into storage;

[0030] 2. Preparation of potassium perchlorate type primer: 50g of the treated potassium perchlorate and lead cyanide raw materials are each taken, poured into a stainless steel basin, and slowly added with a special concentration of nitrolacquer binder solution of 20% shellac 40ml wet mixed for 30min~40min, dried for 1 hour and then granulated, passed through 40 mesh and 20 mesh standard sieves respectively, and the 40 mesh sieve and the 20 mesh sieve were taken, dried and put into storage;

[0031] 3. Use AN and potassium perchlorate type primary explosives as the first and second agents for MGG respectively. The quality of ammonium nitrate (AN) type (AN) agent and potassium perchlorate type primary explosives can be determined by the volume ratio of the agent particles, the total weight ratio and the burning rat...

Embodiment 2-3

[0033] The preparation method is the same as in Example 1, and the usage ratio of various materials is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com