Martensitic stainless steel forge piece material with low-temperature resistance and high strength

A martensitic stainless steel, high-strength technology, applied in the field of forged steel, can solve the problems of poor low-temperature resistance, low cost, inability to meet low-temperature resistance, corrosion resistance, and high strength at the same time, and achieve good low-temperature resistance and high strength , Performance heat treatment process optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

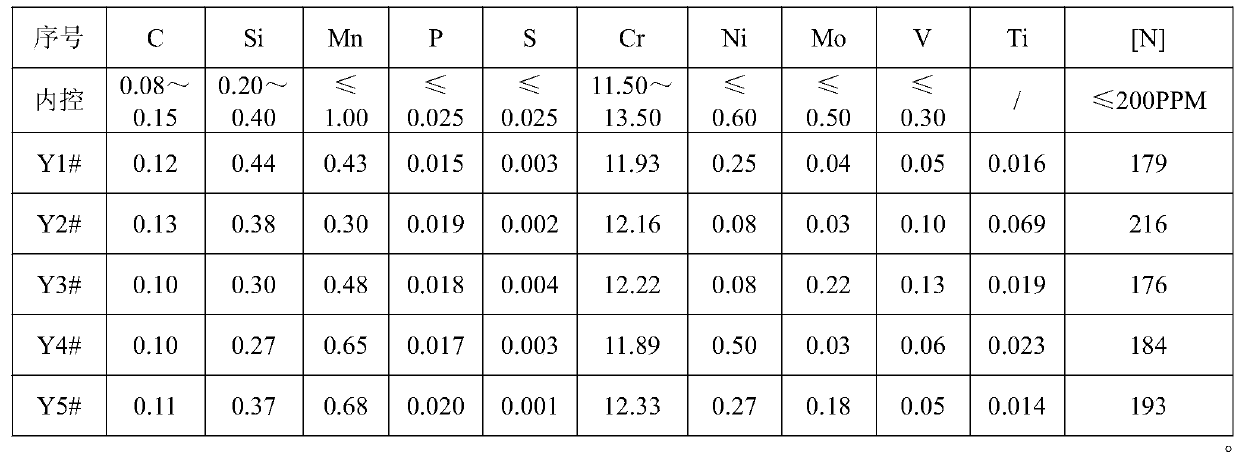

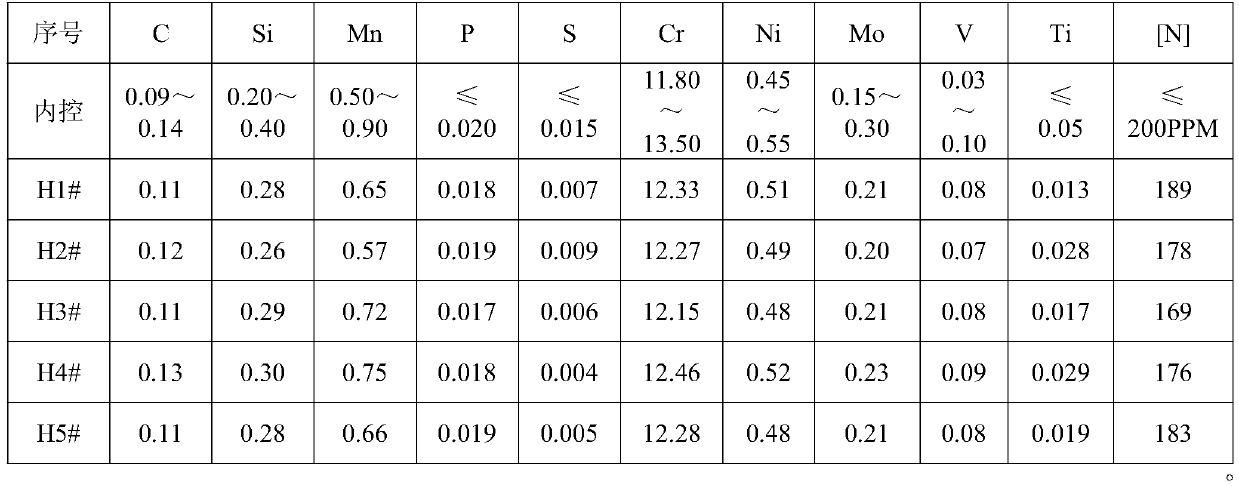

[0037] The present invention will be described in detail below in combination with specific embodiments.

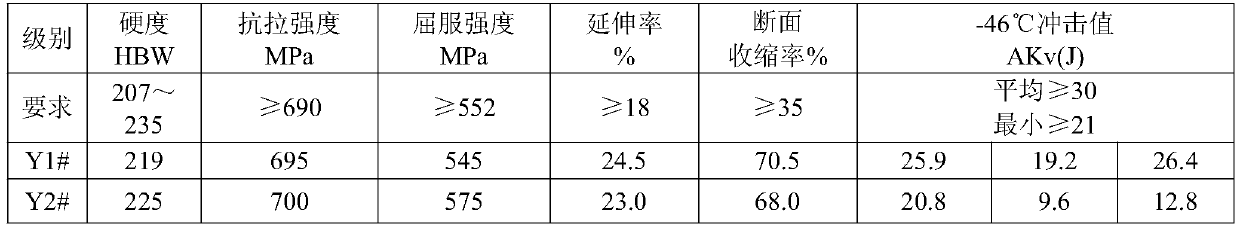

[0038] The present invention designs the technical field of steel forging, and discloses a low-temperature-resistant high-strength martensitic stainless steel forging material. The steel can not only meet the chemical composition requirements of American API 6A martensitic stainless steel, but also meet the Chinese national standards GB and The chemical composition requirements of martensitic stainless steel of American Society for Materials ASTM and American Iron and Steel Institute AISI have expanded the scope of application of materials. And the cost is also taken into consideration, while reducing the cost, it can meet the requirements of excellent toughness, low temperature and high strength performance. After quenching and tempering, when the hardness is in the range of 207-237HBW, the mechanical properties can reach the following properties: tensile strength ≥ 690MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com