A pile foundation construction method

A construction method and pile foundation technology, which can be applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low single pile bearing capacity, low engineering cost, friction, impact, etc., to reduce transportation costs and improve load capacity , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

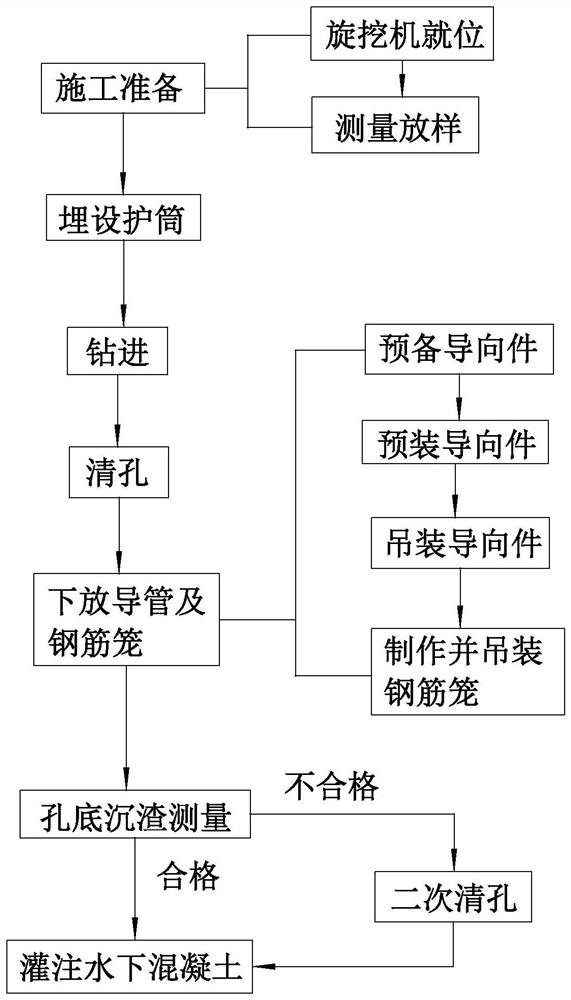

[0039] refer to figure 1 , is a kind of pile foundation construction method disclosed by the present invention, comprises the following steps:

[0040] Step S1, construction preparation:

[0041] Step S1.1 Pre-construction preparation The clear water well should be dug in an area without piles, and the proximity to the mud pool can bring convenience for water replenishment. The mud pool should be dug in an area without engineering piles near the main building. Firstly, the bulldozer is used to level the site. After the equipment enters the site, installation and commissioning are carried out, and the piling sequence is determined according to the site construction conditions.

[0042] Step S1.2 Measure and stake out. After the site is leveled, make a measurement control network according to the design coordinate points, position according to the plane setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com