Non-damage SMA self-resetting steel frame joint

A self-resetting, non-damaged technology, applied in building components, building types, earthquake-proof, etc., can solve the problems of complex construction, loss and relaxation of prestressed stress, and difficulty in controlling the tension of prestressed tendons, so as to reduce losses, Good ductility and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

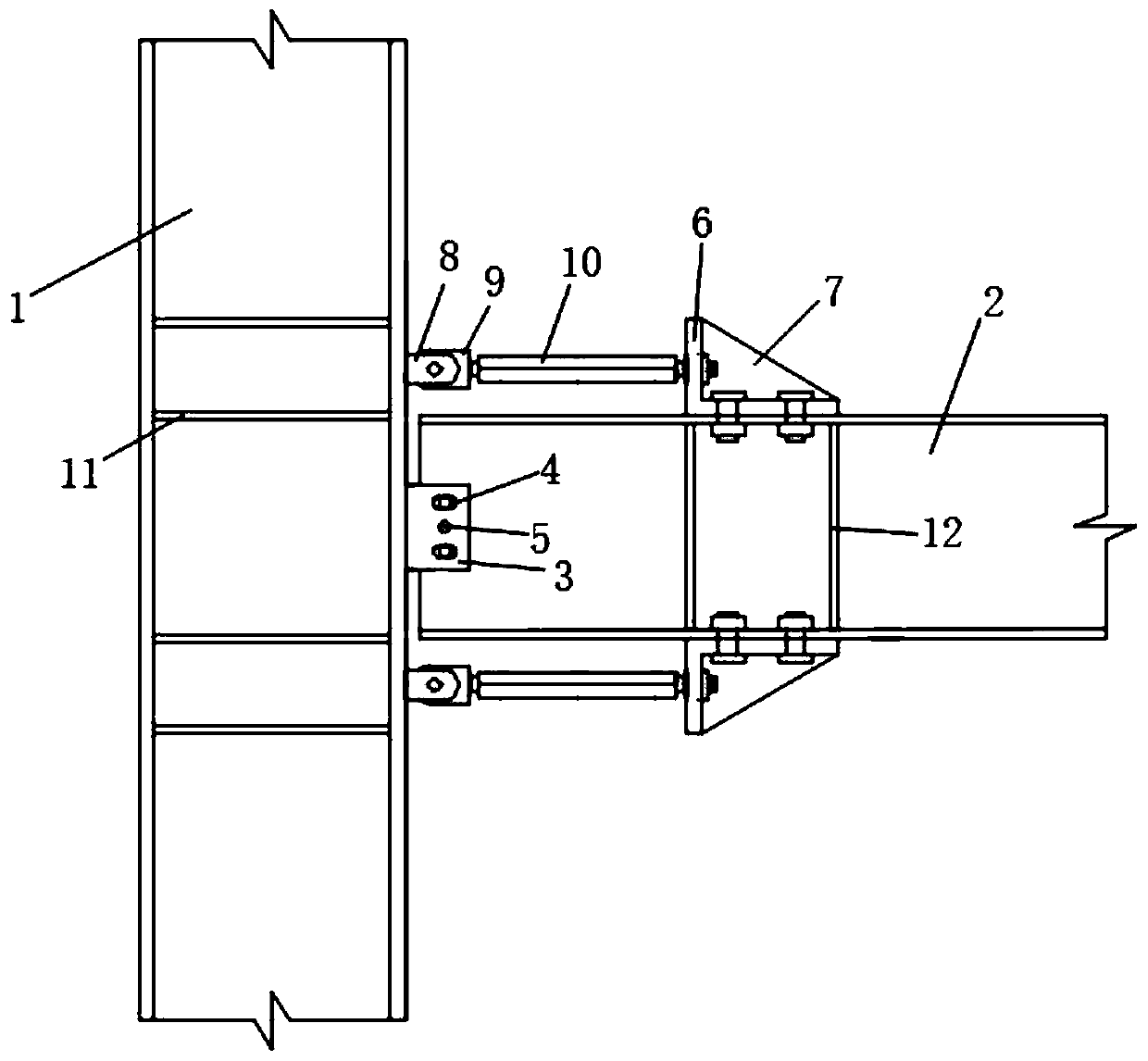

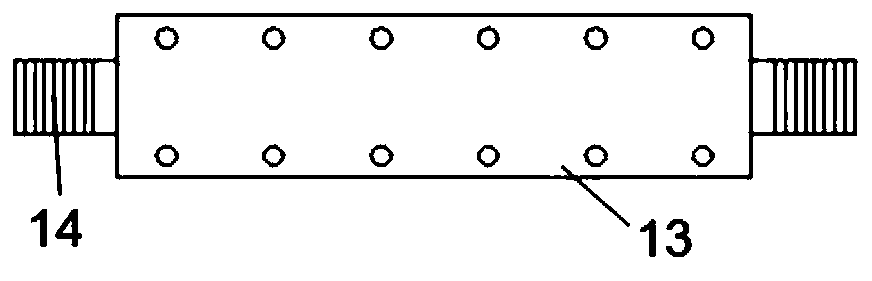

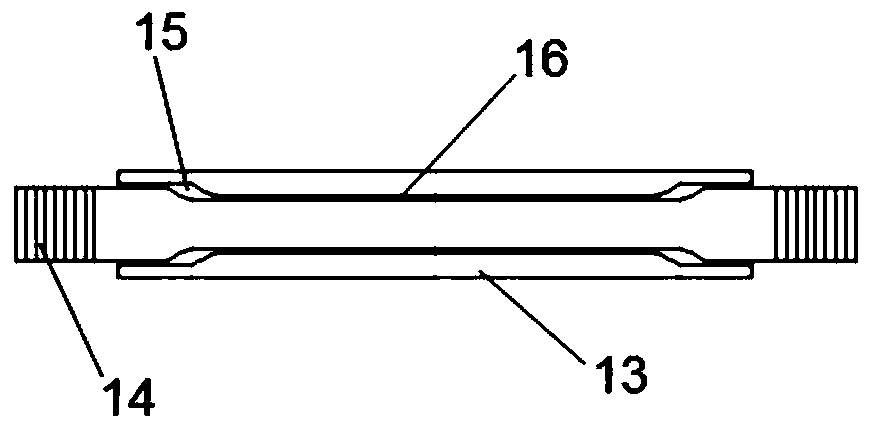

[0029] Such as Figure 1-2 As shown, a non-damage SMA self-resetting steel frame joint, the realization of the joint is as follows: steel beams, steel columns, stiffeners on beam-column webs, bolt holes on the upper and lower flanges of steel beams, angle steel, stiffeners on angle steel Ribs and bolt holes, shear plates, bolt holes and slotted holes in shear plates, connecting plates, lug plates, buckling restraint sleeve plates, working sections of SMA mandrels and external threads at both ends are all prefabricated in the factory. Then transport to the construction site. Firstly, the shear plate (3), upper and lower ear plates (8) on both sides are welded to the column flange. Afterwards, high-strength bolts are used to connect the steel beam (2) and the steel column (1) together through the shear plate (3), and the initial and final tightening o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com