Battery cycle tester and testing method thereof

A technology of battery cycle and test method, which is applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve the problems of increased test cost, large energy consumption, and increased cost, and achieve the effects of reducing test cost, improving conversion efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

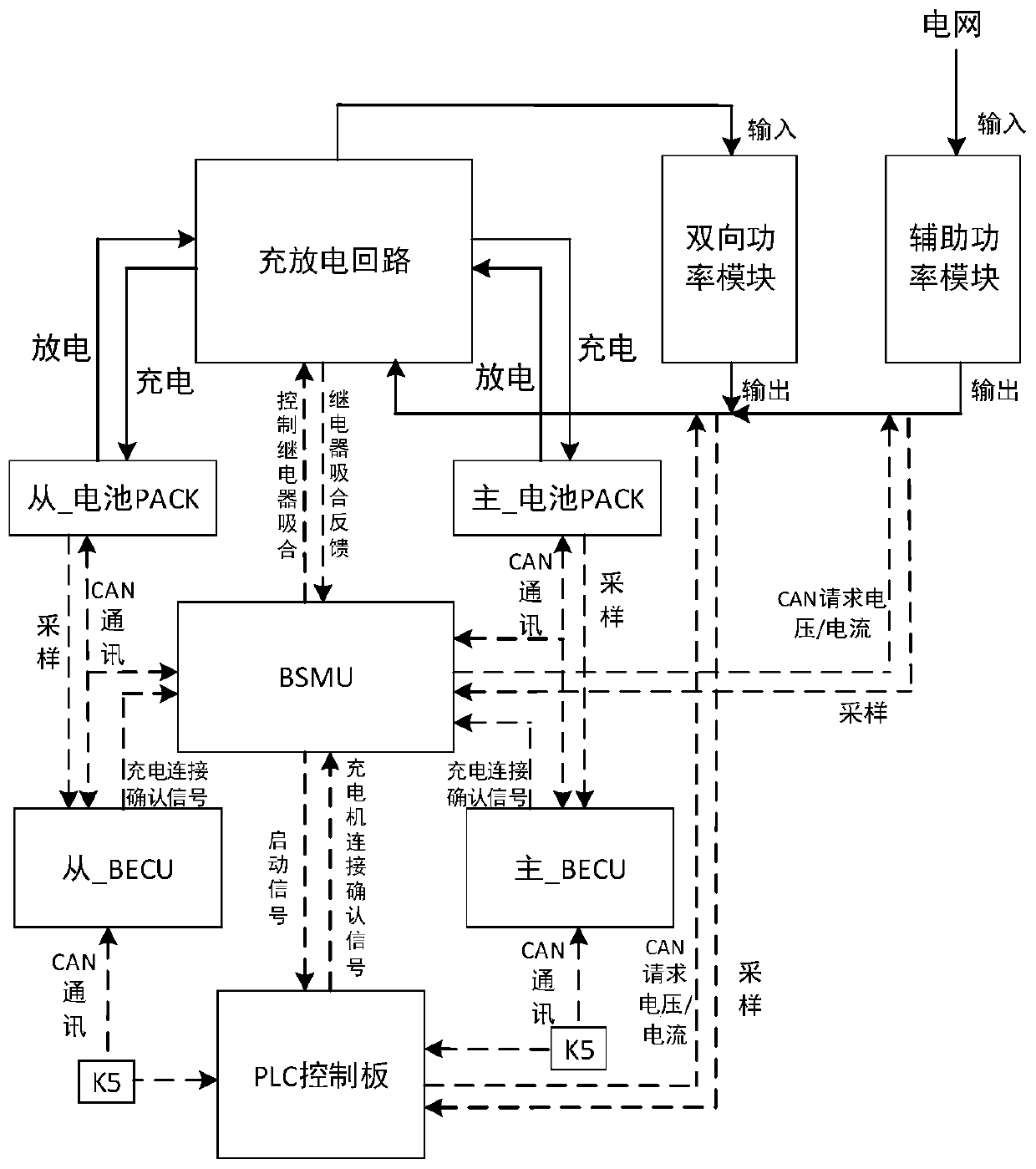

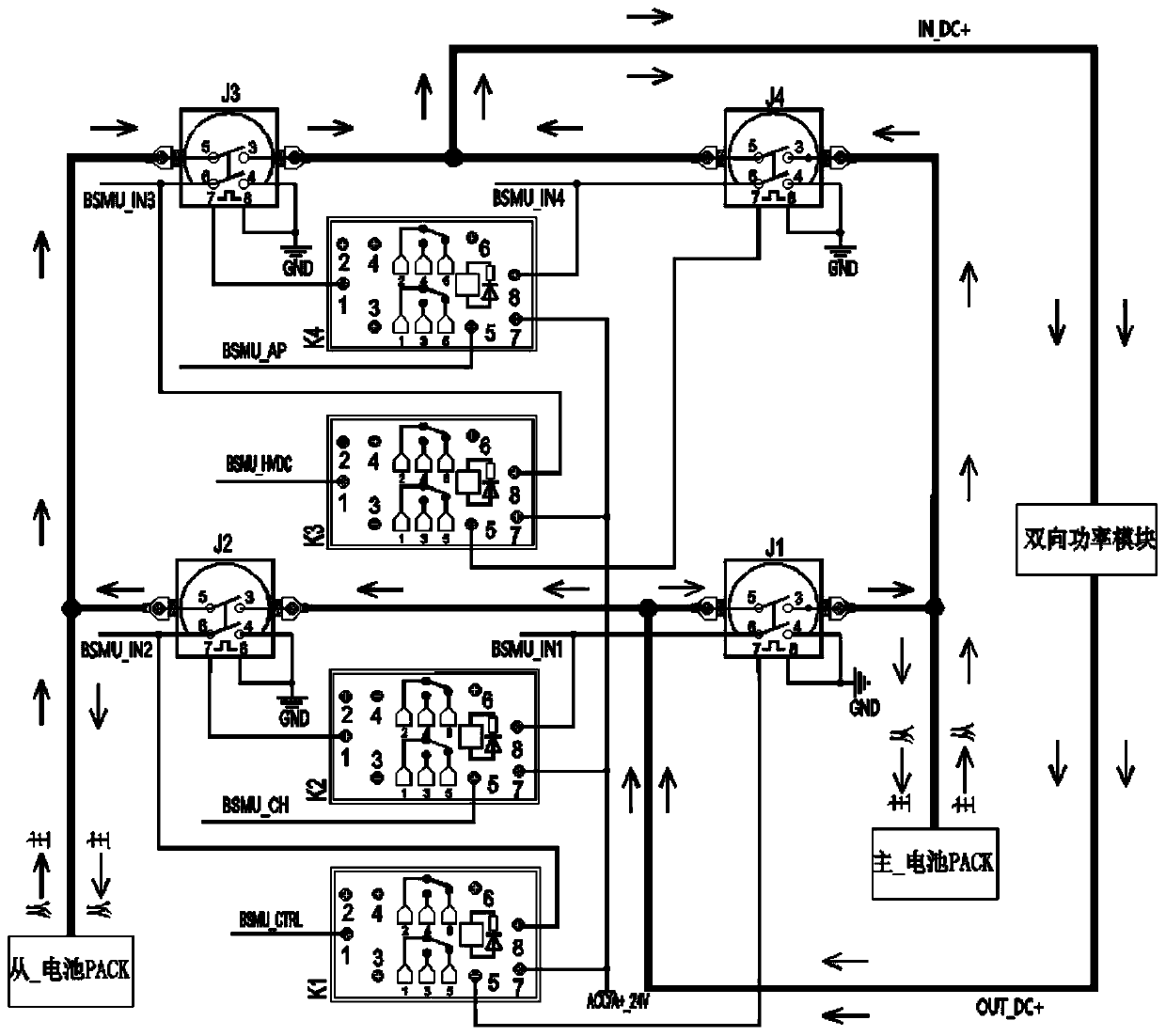

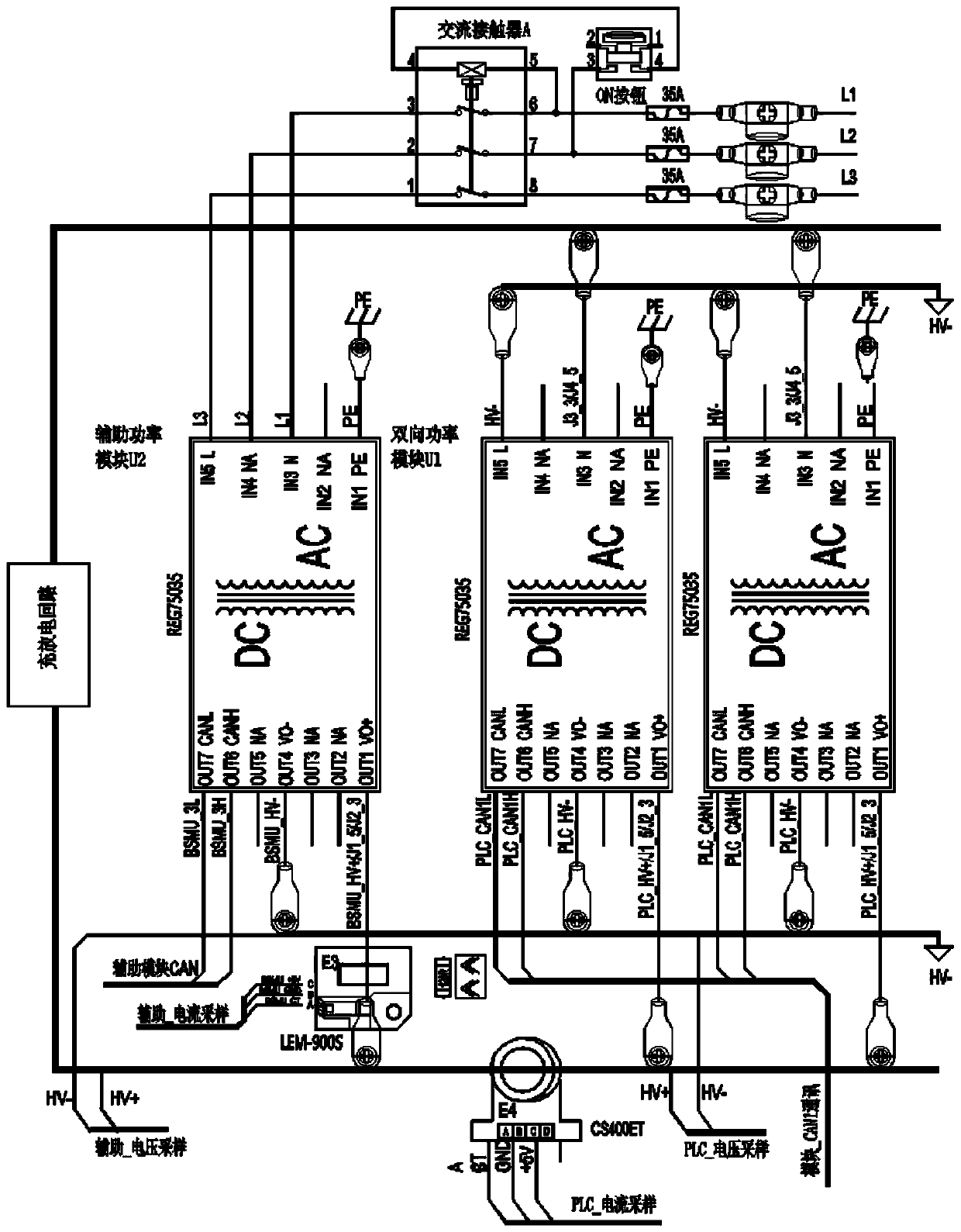

[0040] A battery cycle tester such as figure 1 As shown, including master_battery PACK, slave_battery PACK, charging and discharging circuit, bidirectional power module U1, auxiliary power module U2, master_BECU is BECU1, slave_BECU is BECU2, BSMU, PLC control board, for switching charging Direction relay K5, master_battery PACK_screen, slave_battery PACK_screen, charger screen and battery cycle test screen, the slave_battery PACK is the tested battery PACK, and the master_battery PACK is 8 sequentially The battery PACK groups PACK11-PCK18 connected in series, the slave_battery PACK is 8 sequentially connected battery PACK groups PACK21-PCK28, the bidirectional power modu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap