Glue overflow detection device and glue overflow detection method

A detection device and glue overflow technology, which is applied in optical device exploration and other directions, can solve the problems of low detection accuracy, low detection efficiency, and affecting the detection accuracy of infrared proximity sensing holes, etc., and achieve the effect of simple detection method and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

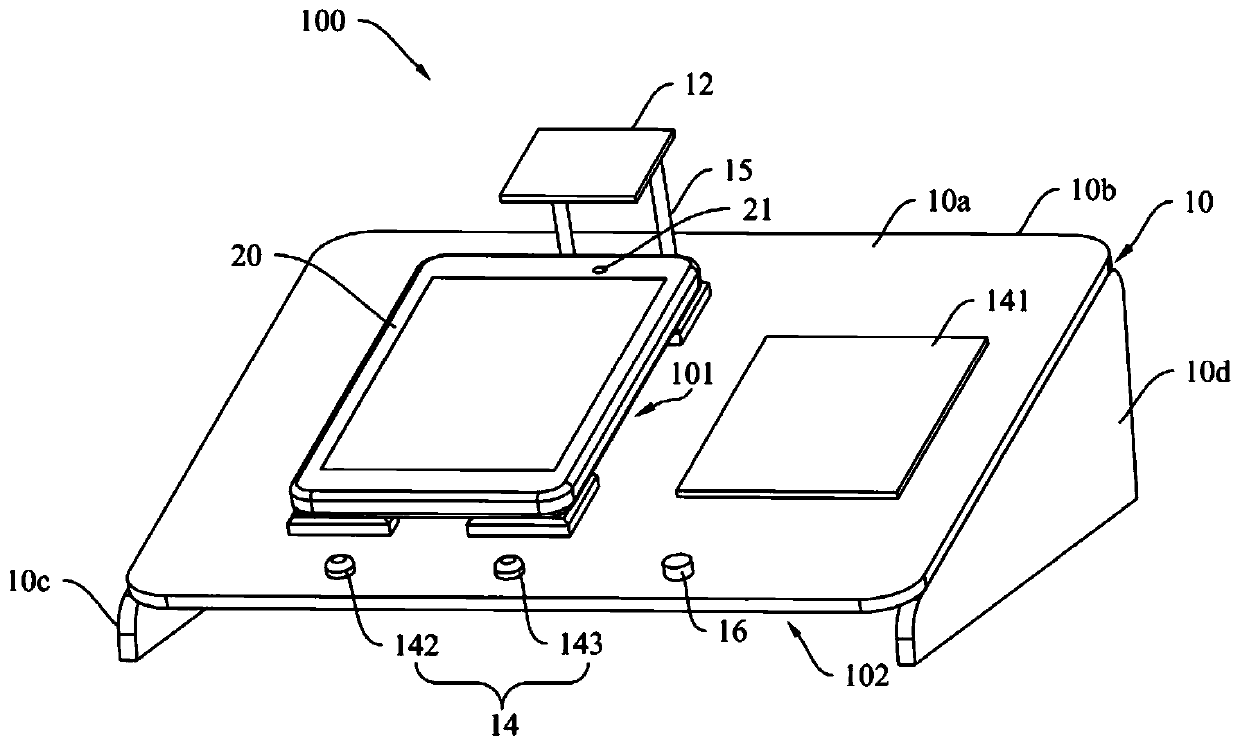

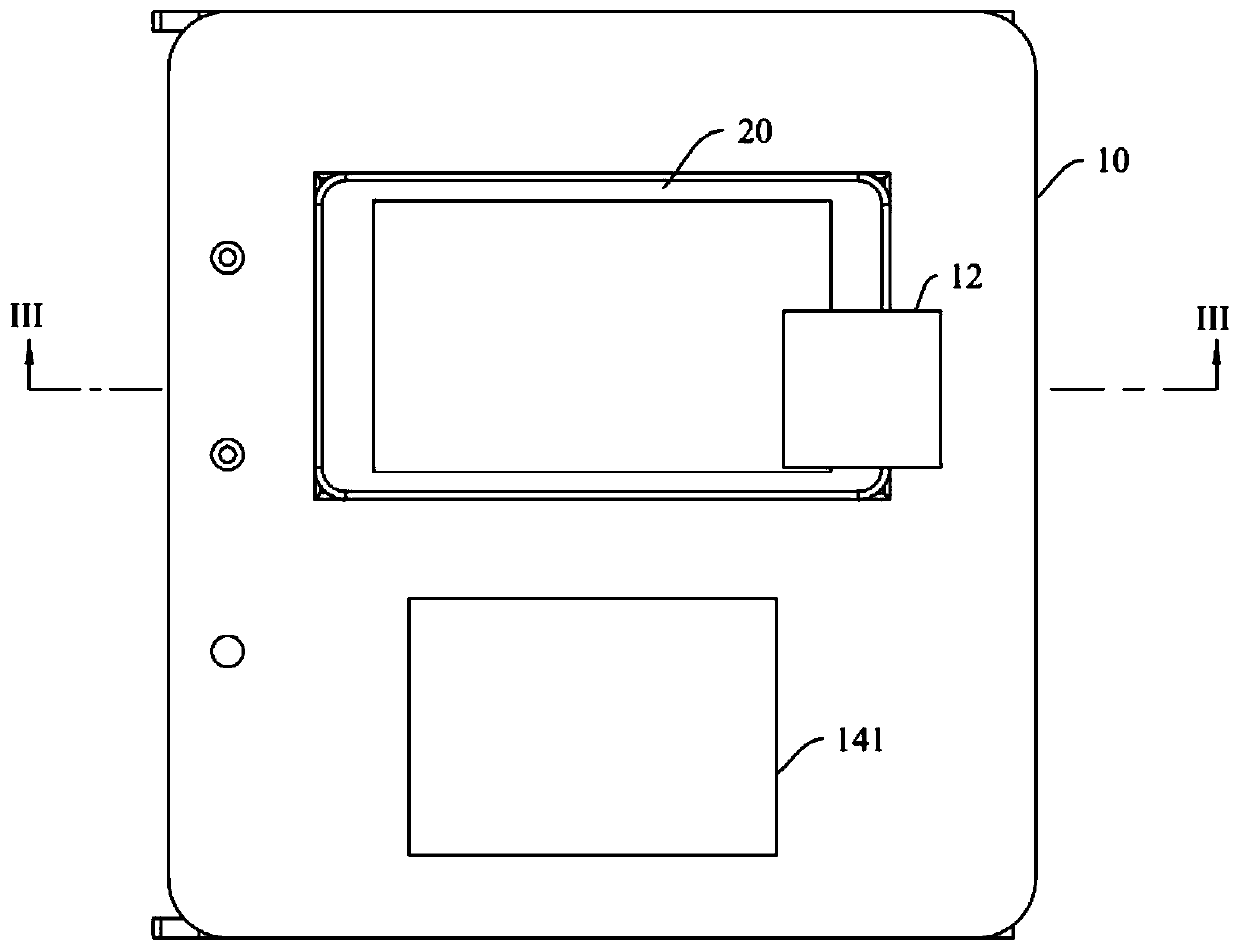

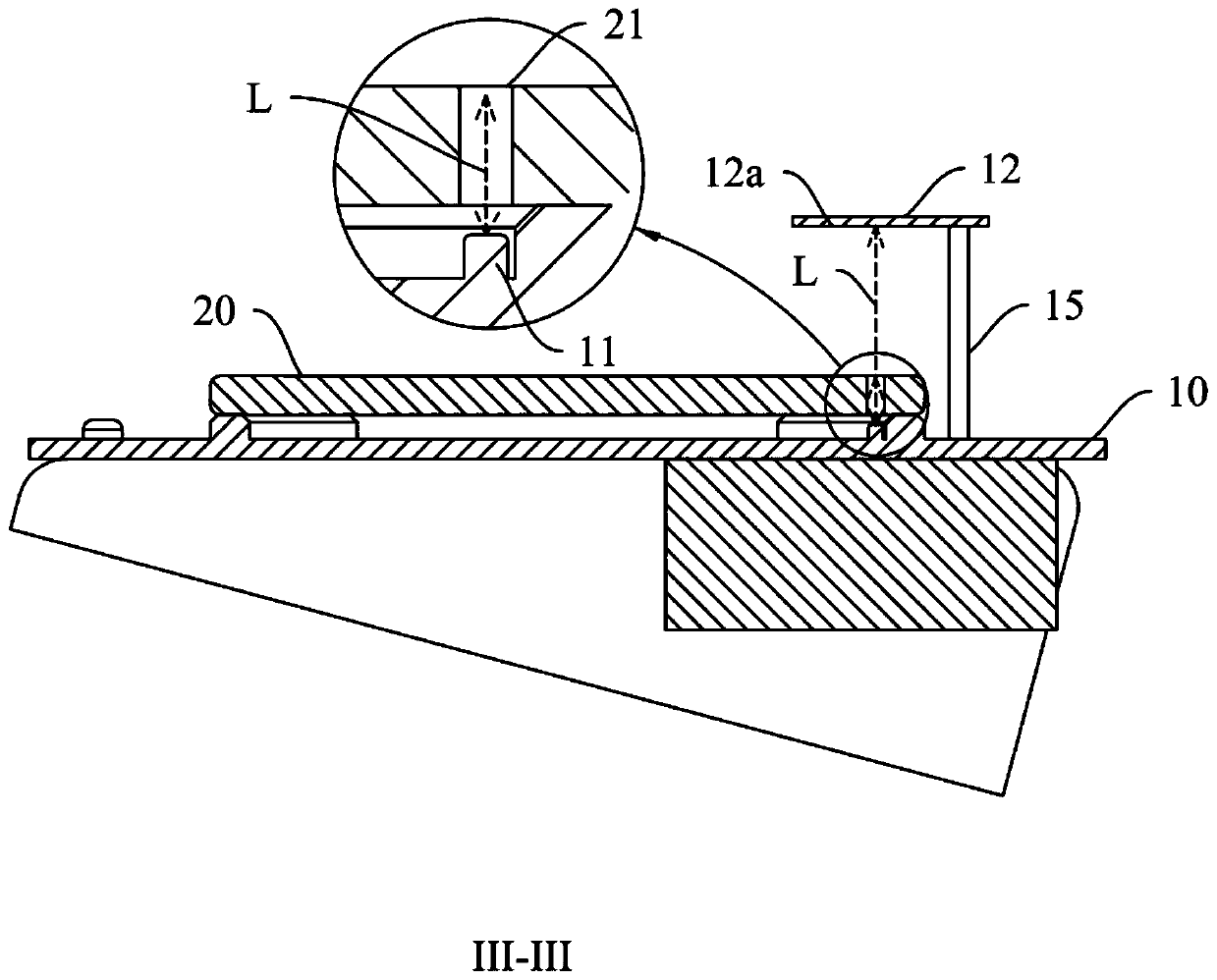

[0037] Please also refer to Figure 1 to Figure 4 , figure 1 shows a schematic structural view of the screen assembly of the electronic device placed in the glue overflow detection device of the present invention, figure 2 yes figure 1 side view, image 3 yes figure 2 Sectional view of III-III in, Figure 4 A schematic diagram of the screen assembly of the electronic device not placed in the glue overflow detection device is shown in . The glue overflow detection device 100 of this embodiment is used to detect the infrared proximity sensing hole 21 on the screen assembly 20 of the electronic device, so as to determine whether the infrared proximity sensing hole 21 has glue overflow or hole blocking phenomenon. The glue overflow detection device 100 of the present embodiment includes a detection table 10, an optoelectronic device 11, a baffle 12, and a controller 13 (see Figure 5 shown) and the output unit 14. Wherein, there is a positioning position 101 on the table ...

Embodiment 2

[0063] Please also refer to figure 1 and Figure 6 , Figure 6 It is a flowchart of the glue overflow detection method disclosed in Embodiment 2 of the present invention. The glue overflow detection method in this embodiment 2 is realized by using the glue overflow detection device 100 in the above-mentioned embodiment 1. The glue overflow detection method includes:

[0064] 201. Place the screen assembly of the electronic device on the table top of the inspection table, and make the infrared proximity sensing hole on the screen assembly correspond to the optoelectronic device.

[0065] In this embodiment, during detection, the screen assembly 20 needs to be placed on the positioning position 101 of the detection table 10, and the position of the screen assembly 20 should be kept so that the screen assembly 20 remains still during the detection process. Avoid the displacement of the screen component 20 from affecting the detection result.

[0066] As an optional implementa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com