A kind of graphene-gold bonding wire and its preparation method and application

A graphene and bonding wire technology, used in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc. The effect of high tensile strength, improved bonding performance and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

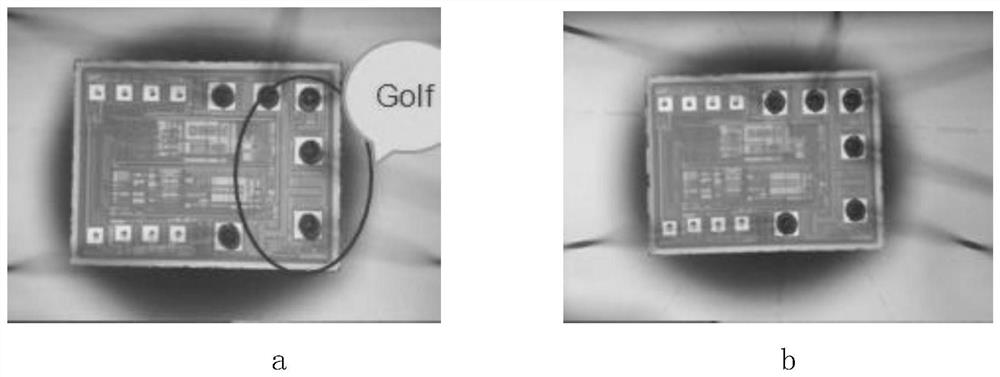

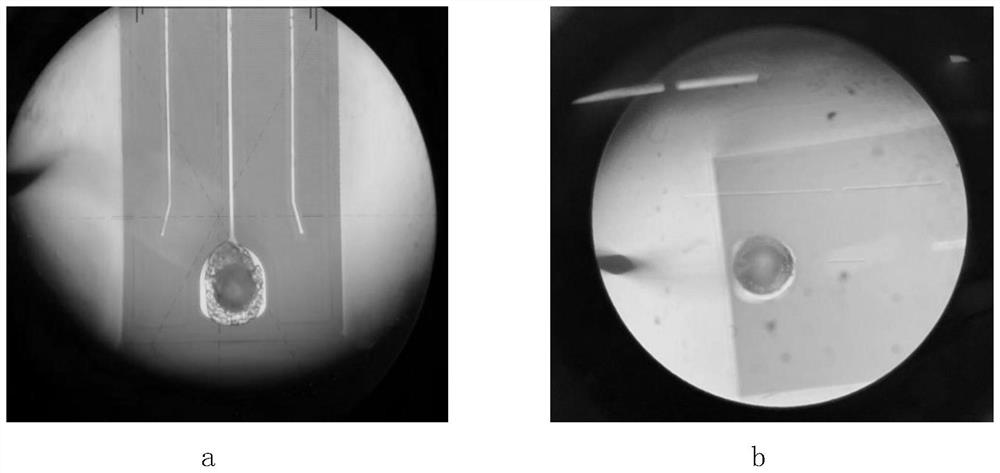

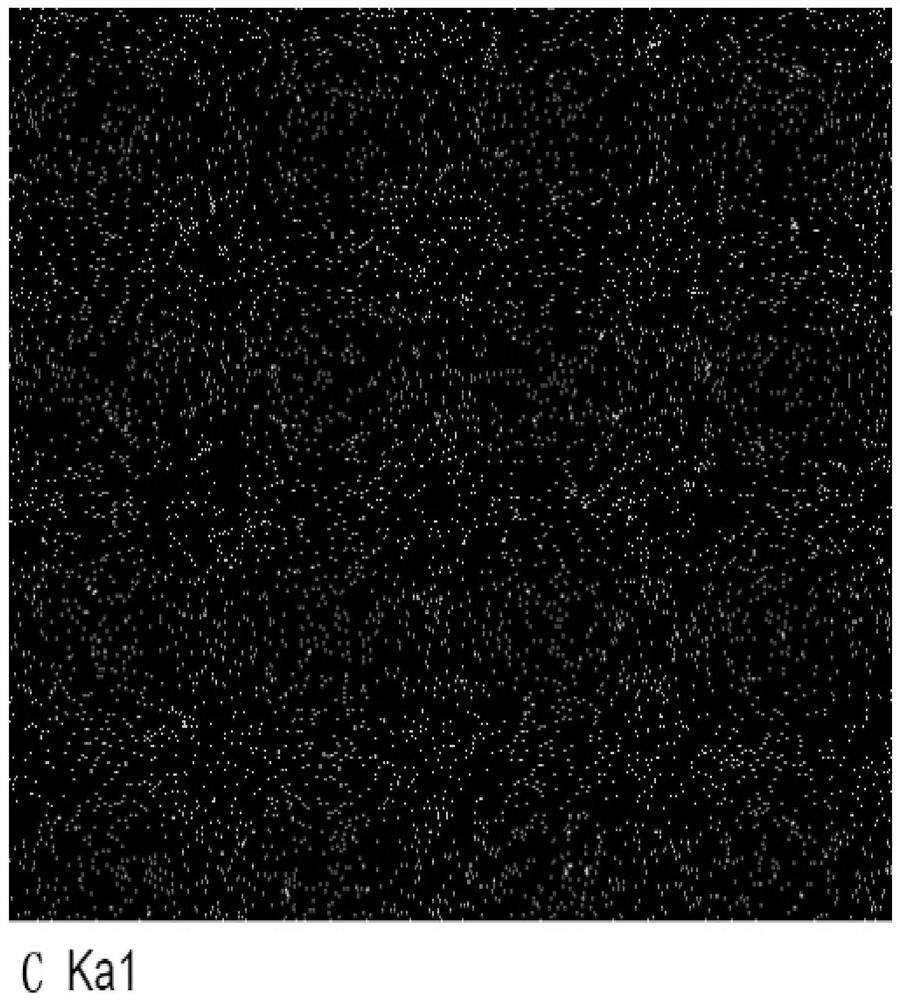

Image

Examples

Embodiment 1

[0038] A graphene-gold bonding wire, comprising: 0.05% graphene, 0.0005% lanthanum, 0.0005% cerium, 60% gold, 39.947% silver, and the balance is unavoidable impurities.

[0039] The preparation method of above-mentioned graphene-gold bonding wire, comprises the following steps:

[0040] S11, prepare graphene-gold composite powder material:

[0041] Prepare AuCl with a concentration of 0.12mol / L 3 Aqueous solution 5L.

[0042] Graphene with a quality of 8g was placed in the prepared AuCl 3 In the aqueous solution, apply electromagnetic stirring and ultrasonic dispersion at the same time, adjust the pH value of the solution to 13 with a concentration of 20wt% ammonia water, and drop in a formaldehyde reducing agent with a concentration of 15wt% under the condition of a reaction temperature of 60°C to 90°C Carry out reduction, rinse and filter with deionized water after the reaction is completed, place the collected reaction product in a drying oven to dry, and obtain a graphe...

Embodiment 2

[0065] A graphene-gold bonding wire, comprising: 0.1% graphene, 0.0008% lanthanum, 0.0010% cerium, 70% gold, 29.898% silver, and the balance is unavoidable impurities.

[0066] The preparation method of above-mentioned graphene-gold bonding wire, comprises the following steps:

[0067] S21, prepare graphene-gold composite powder material:

[0068] Prepare AuCl with a concentration of 0.13mol / L 3 Aqueous solution 8L.

[0069] Graphene with a quality of 10g was placed in the prepared AuCl 3 In the aqueous solution, apply electromagnetic stirring and ultrasonic dispersion at the same time, adjust the pH value of the solution to 14 with ammonia water with a concentration of 30wt%, and drop in a formaldehyde reducing agent with a concentration of 30wt% under the condition of a reaction temperature of 60°C to 90°C Carry out reduction, rinse and filter with deionized water after the reaction is completed, place the collected reaction product in a drying oven to dry, and obtain a g...

Embodiment 3

[0093] A graphene-gold bonding wire, comprising: 0.90% graphene, 0.0010% lanthanum, 0.0100% cerium, 80% gold, 19.086% silver, and the balance is unavoidable impurities.

[0094] The preparation method of above-mentioned graphene-gold bonding wire, comprises the following steps:

[0095] S31, prepare graphene-gold composite powder material:

[0096] Prepare AuCl with a concentration of 0.15mol / L 3 Aqueous solution 10L.

[0097] Graphene with a quality of 15g was placed in the prepared AuCl 3 In the aqueous solution, apply electromagnetic stirring and ultrasonic dispersion at the same time, adjust the pH value of the solution to 13 with a concentration of 20wt% ammonia water, and drop in a formaldehyde reducing agent with a concentration of 40wt% under the condition of a reaction temperature of 60°C to 90°C Carry out the reduction, rinse and filter with deionized water after the reaction is completed, place the collected reaction product in a drying oven to dry, and obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com