Fuel delivery device for cryogenic fuels

A technology of fuel delivery and low-temperature fuel, which is applied to fuel injection devices, fuel supply devices, fuel injection pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

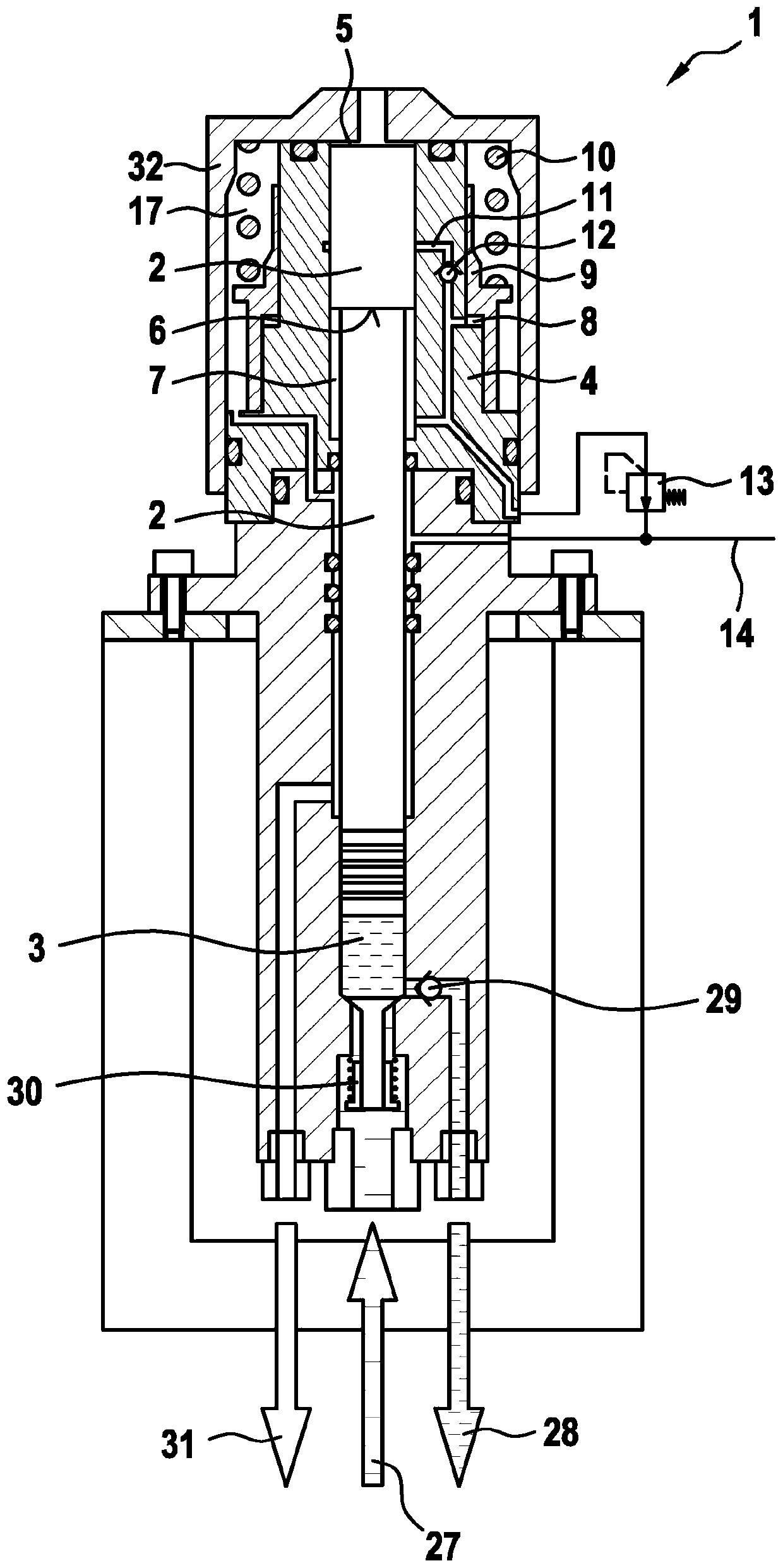

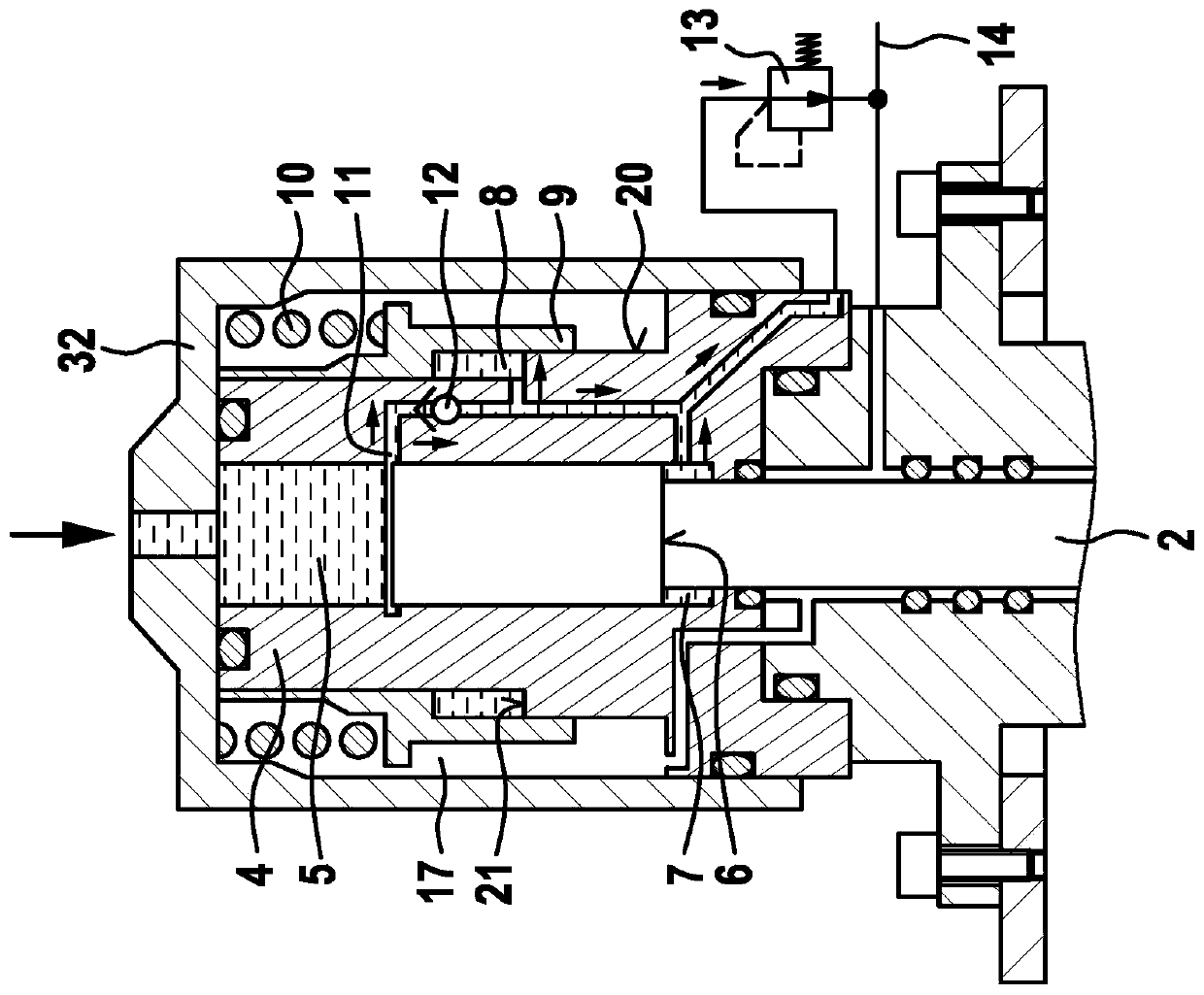

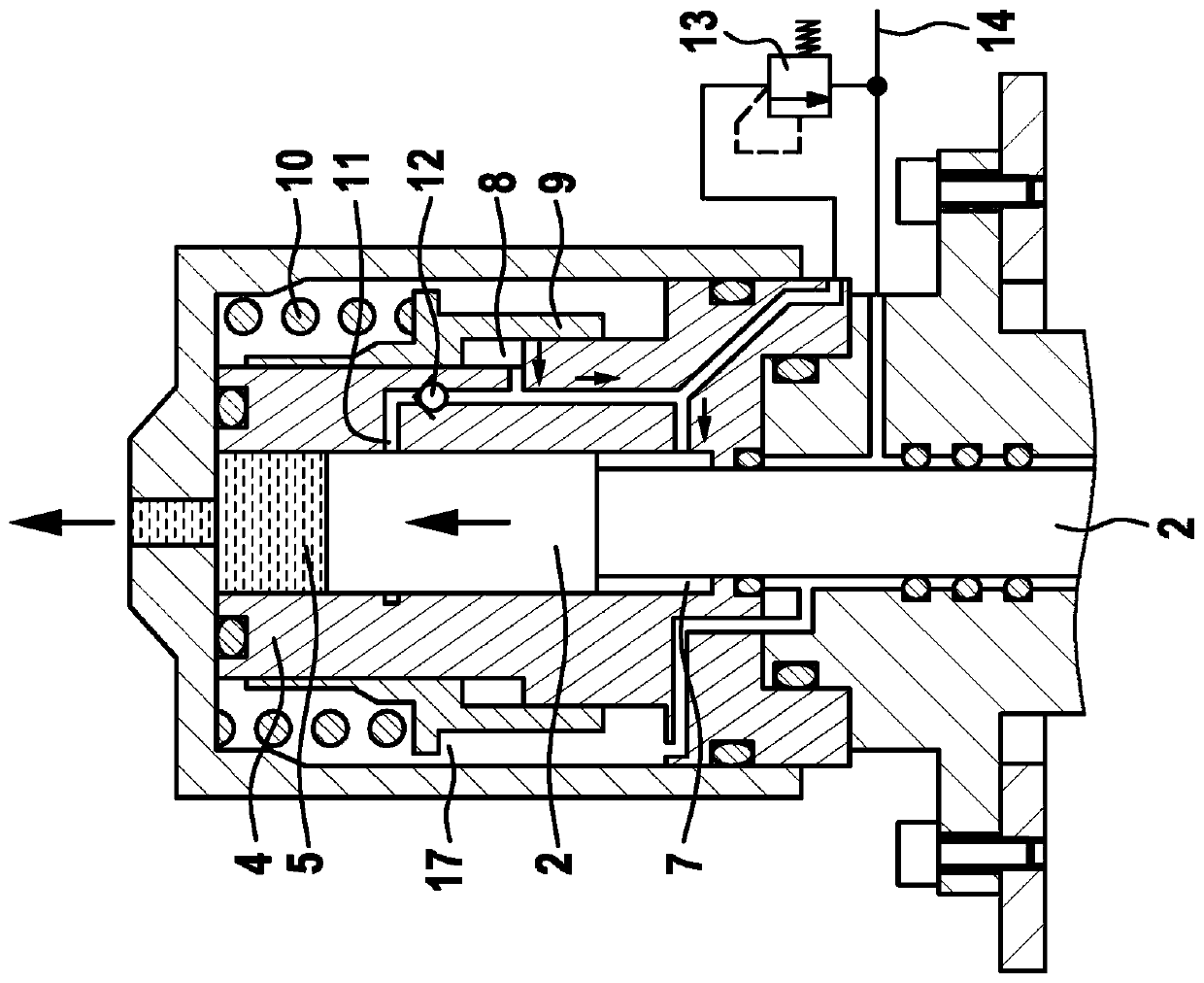

[0035] exist figure 1 The fuel delivery device according to the invention shown in is used to supply fuel to an internal combustion engine (not shown) of a motor vehicle, wherein the fuel is a cryogenic fuel, preferably natural gas. The fuel delivery device comprises a piston pump 1 for delivering fuel to high pressure.

[0036] Fuel is stored in liquid form in tanks (not shown). Via the inflow opening 27 and the suction valve 30 , the fuel reaches the compression chamber 3 of the piston pump 1 , which is delimited by the reciprocating pump piston 2 . During the working stroke of the pump piston 2 , the fuel present in the compression chamber 3 is compressed and supplied via the outflow opening 28 to a buffer accumulator (not shown). A non-return valve 29 is arranged in the region of the outflow opening 28 in order to prevent fuel from flowing back into the compression chamber 3 during a new suction stroke of the pump piston 2 . Furthermore, a return line 31 is provided for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com