Clamping and cutting mechanism for remote picking of orchard

A remote and orchard technology, applied in the direction of picking machines, applications, harvesters, etc., can solve problems such as complicated operations and damage to fruit integrity, and achieve the effect of facilitating sales, eliminating the risk of damage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

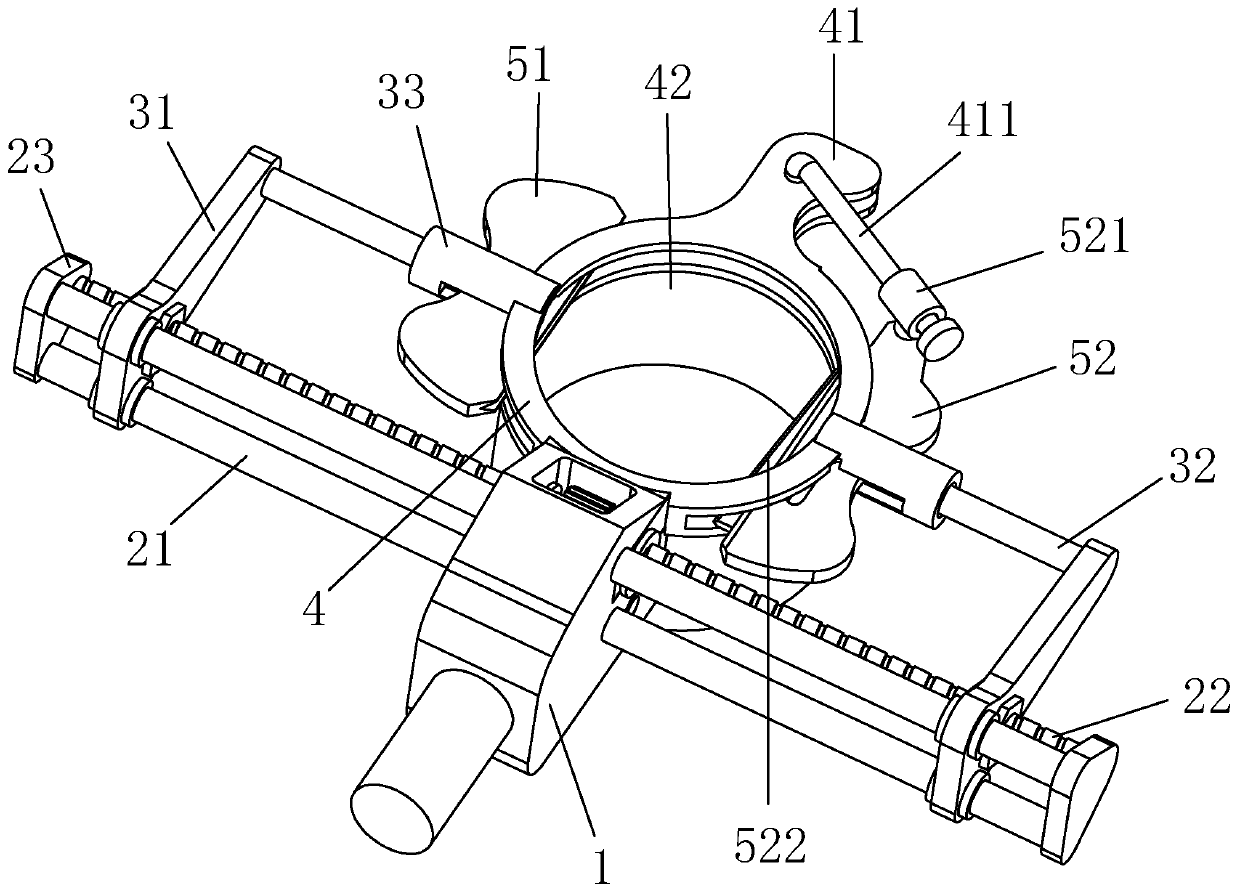

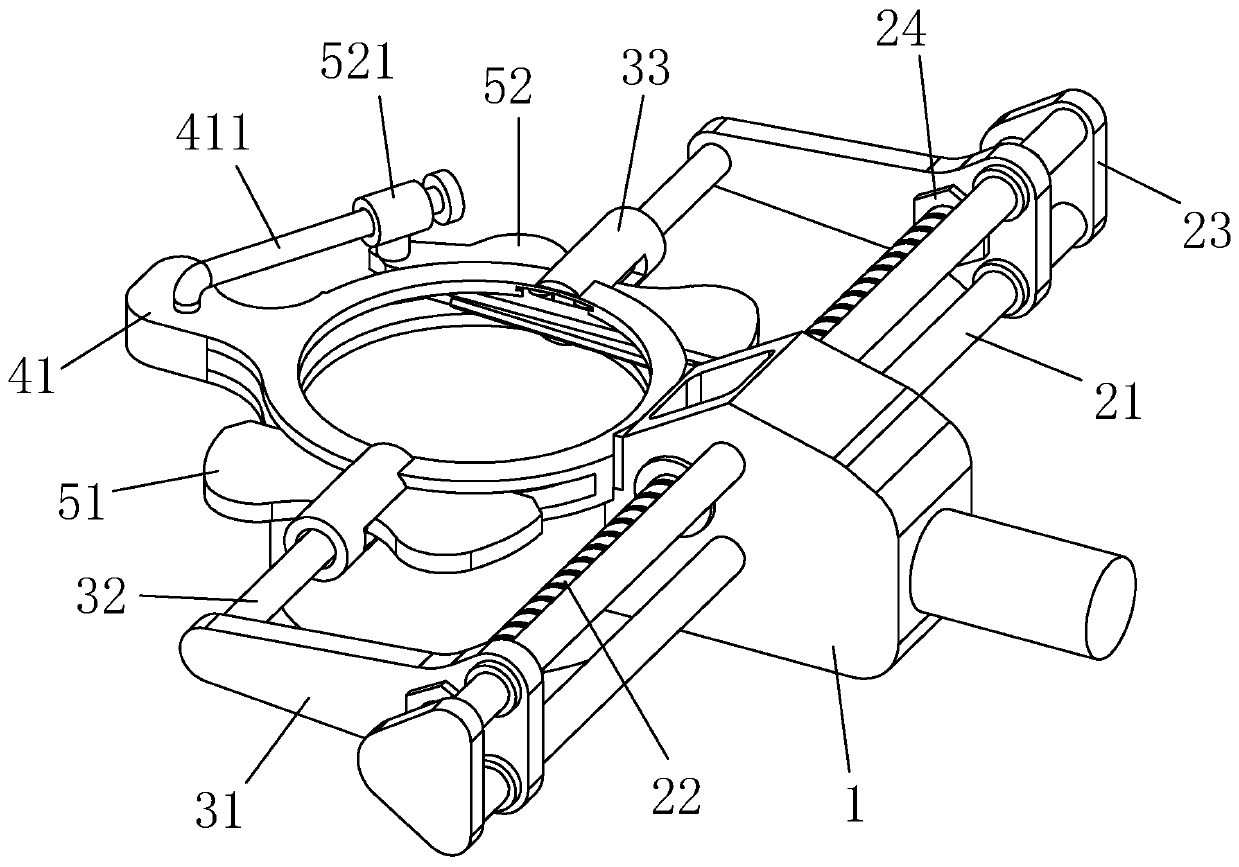

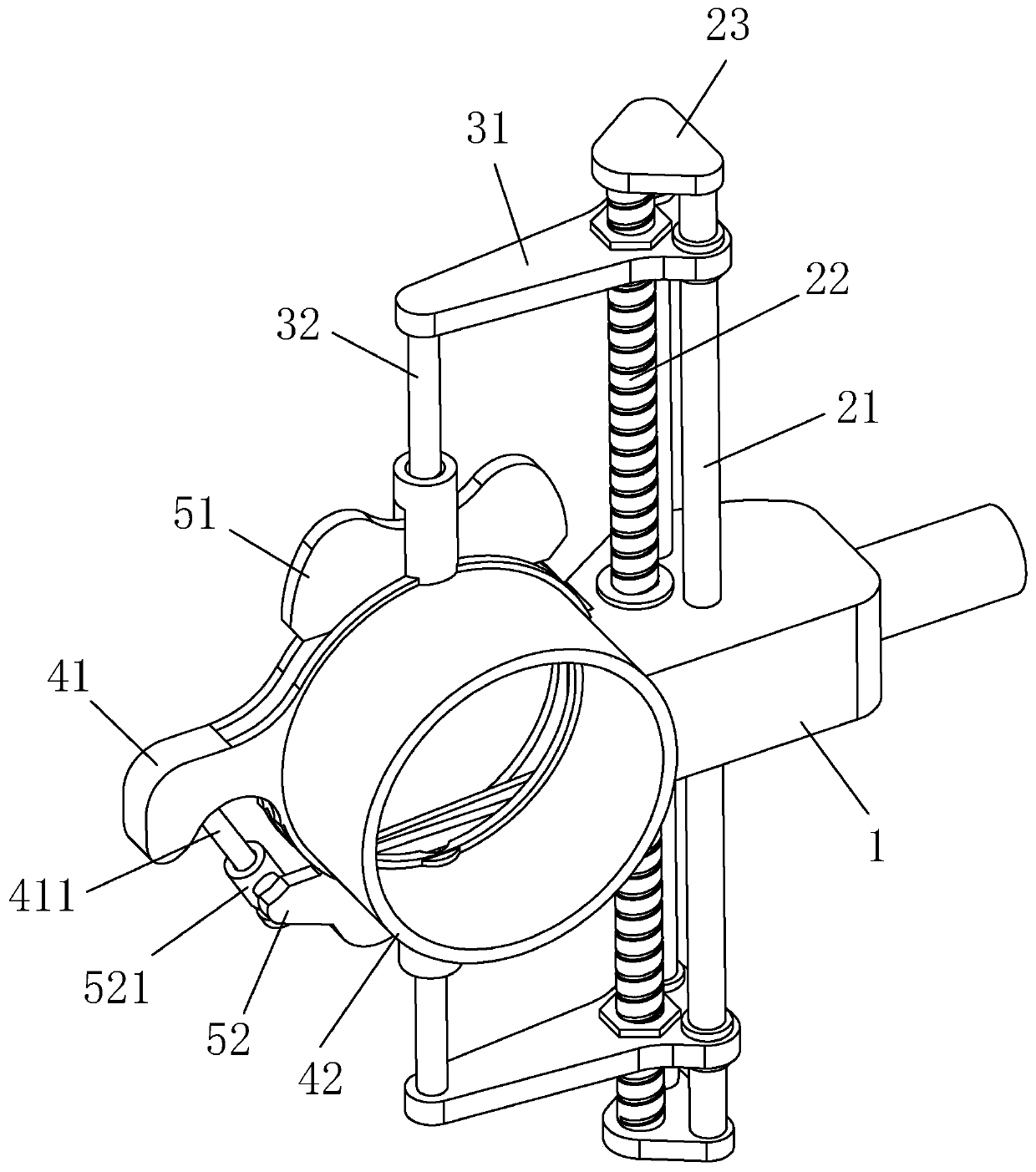

[0044] Such as Figure 1-6 The clamping and cutting mechanism shown includes a mounting ring 4, a power mechanism and two moving mechanisms. The mounting ring 4 is an annular ring, and the center position of the annular ring in the height direction is provided with a gap slot. The number of gap slots is two. Two gap slots are symmetrically distributed about the center of the annular ring, and the two gap slots are used to accommodate the first moving plate 51 and the second moving plate 52 respectively. The mounting ring 4 is fixed at the middle position of the power mechanism. The power mechanism includes a driving part 1, a second guide rod 21 and a threaded rod 22. The driving part 1 is a slow motor. The model of the slow motor is YDS56. A cabinet is fixed on the side, and the slow motor is installed in the cabinet.

[0045] Such as Figure 1-6 As shown, both sides of the driving member 1 are provided with side plates 23, and the two side plates 23 adopt a triangular structure...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is:

[0056] Such as Picture 11 As shown, the first guide rod 411 includes a guide inner end 4111 and a guide outer end 4112. The angle between the guide inner end 4111 and the guide outer end 4112 is an obtuse angle. The guide inner end 4111 and the movement direction of the second moving plate 52 are different. The included angle between the guide outer end 4112 and the movement direction of the second moving plate 52 is smaller than the included angle between the guide inner end 4111 and the guide outer end 4112. An integral structure is adopted between the guide inner end 4111 and the guide outer end 4111. A rounded transition is adopted between the ends 4112.

[0057] In use, the guide sleeve 521 drives the second moving plate 52 to move through the flexible coupling 529. At the same time, the guide sleeve 521 slides along the guide outer end 4112 toward the guide inner end 4111. When the guide sleeve 521 slides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com