Industrial volatile organic pollutant treatment device and use method thereof

A volatile organic and pollutant treatment technology, applied in the field of industrial pollutant treatment, can solve the problems of secondary pollution of solid particles, inconvenient collection and storage of solid particles, inconvenient solid particle treatment, etc., to reduce the risk of secondary pollution, The effect of convenient collection and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

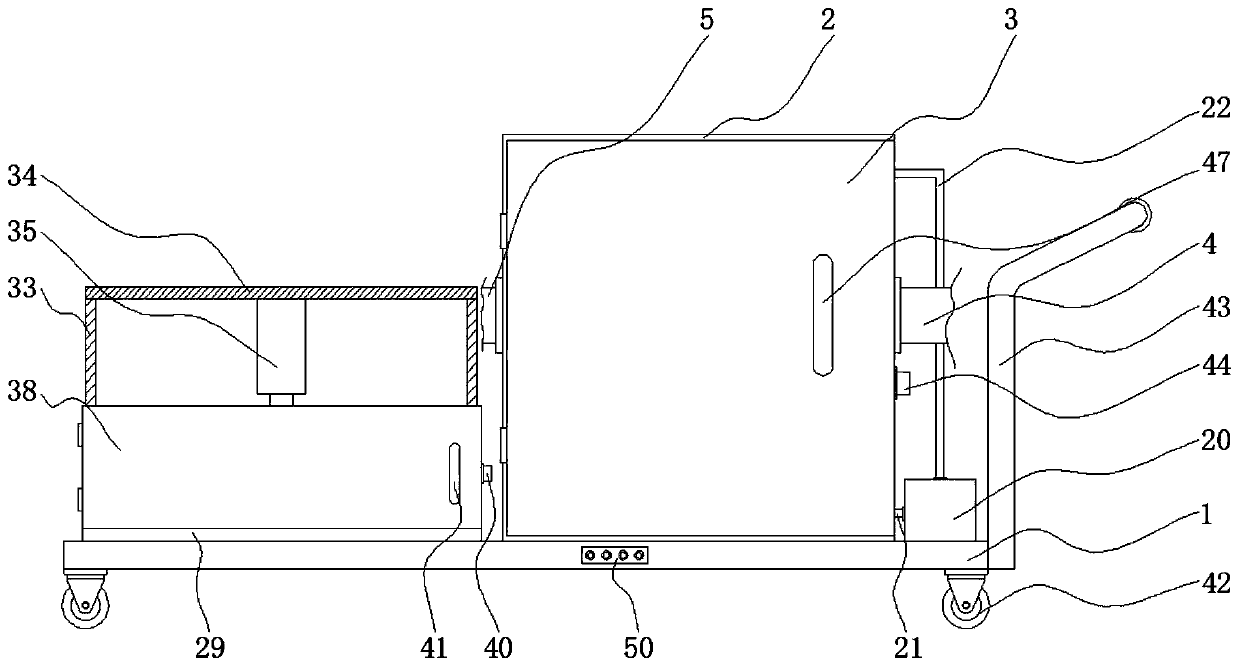

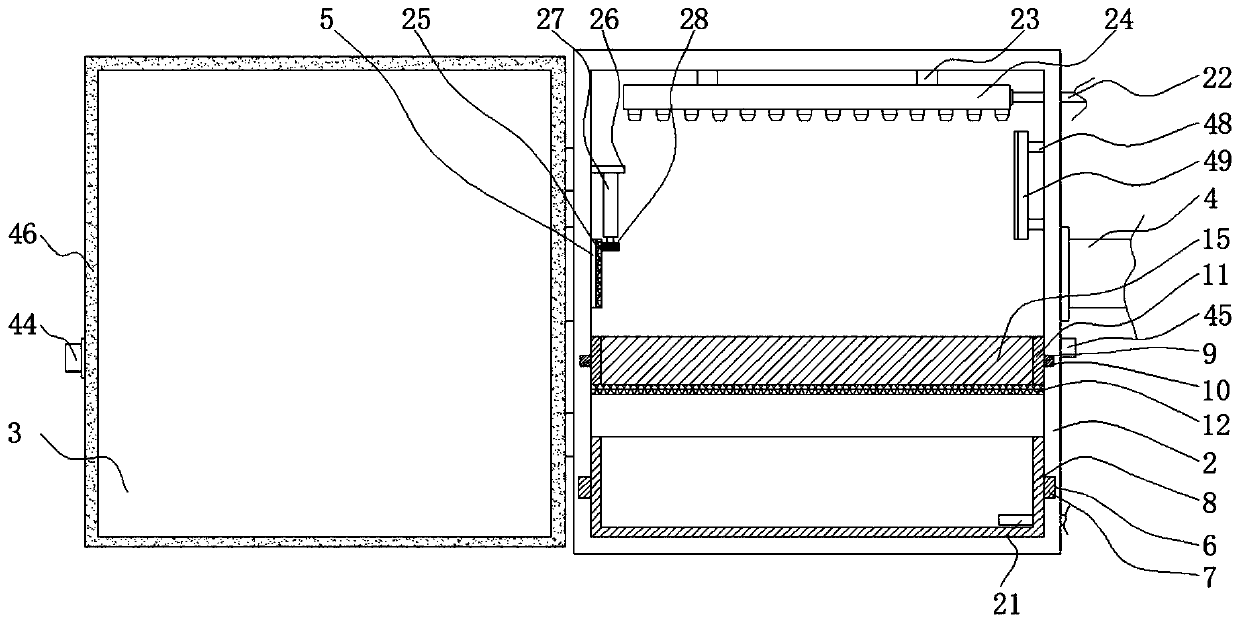

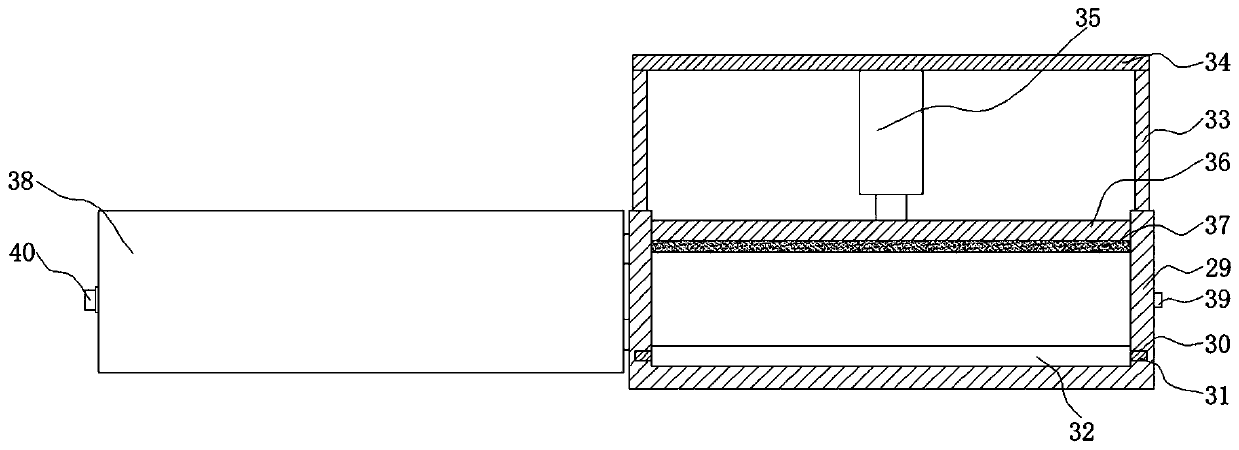

[0026] see Figure 1-5, the present invention provides a technical solution: an industrial volatile organic pollutant treatment device, including a bottom plate 1, the upper surface of the bottom plate 1 is fixedly connected with a cabinet body 2, and the outer walls of the cabinet body 2 are respectively connected with first pipe bodies 4 and the second pipe body 5, the inner side wall of the cabinet body 2 is symmetrically provided with two first chute 6, and the inner side walls of the two first chute 6 are all slidably connected with the first slider 7, and the two first chute The adjacent side of the block 7 is fixedly connected with a water tank 8, and the inner side wall of the cabinet body 2 is located above the first chute 6 and is symmetrically provided with two second chute 9, and the inner side walls of the two second chute 9 all slide The second slider 10 is connected, and the adjacent side of the two second sliders 10 is fixedly connected with a U-shaped plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com