Production equipment for coating powder easy to store

A production equipment and paint technology, applied in the field of paint powder production equipment, can solve the problems of increasing staff, inconvenient storage, and insufficient fineness of paint powder, etc., and achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

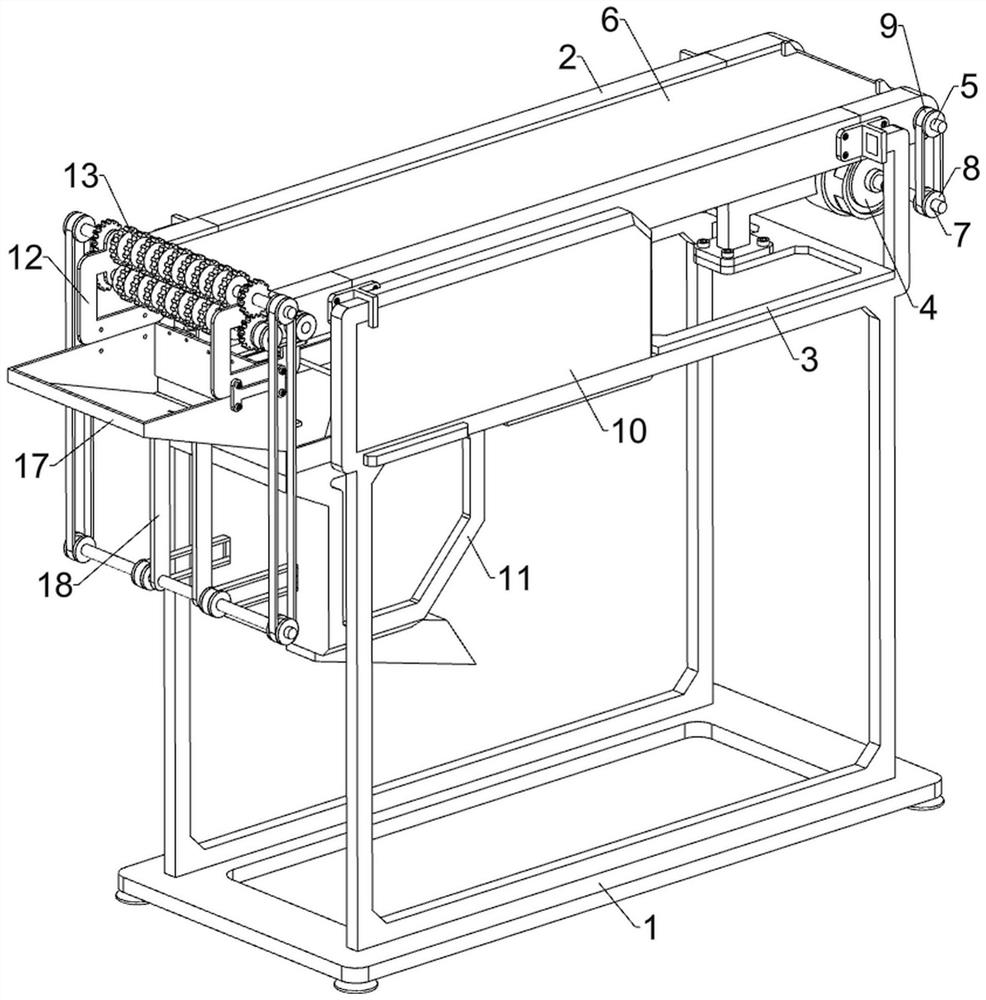

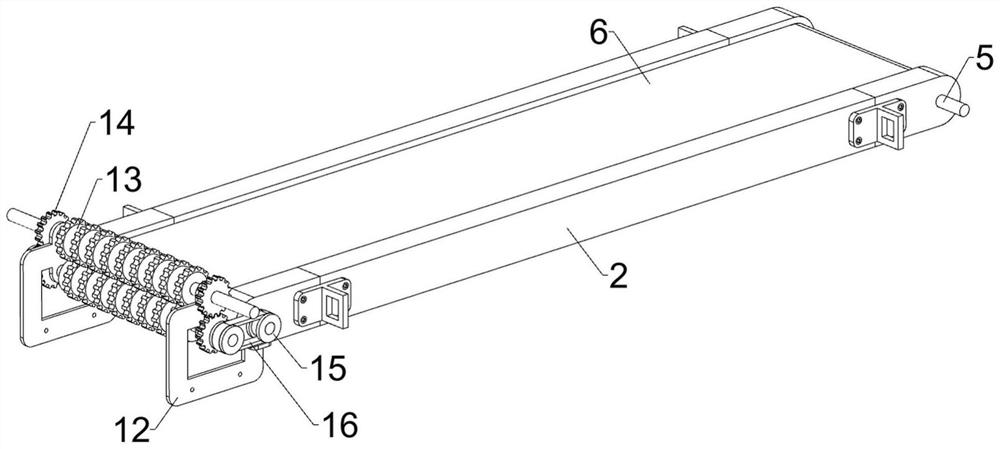

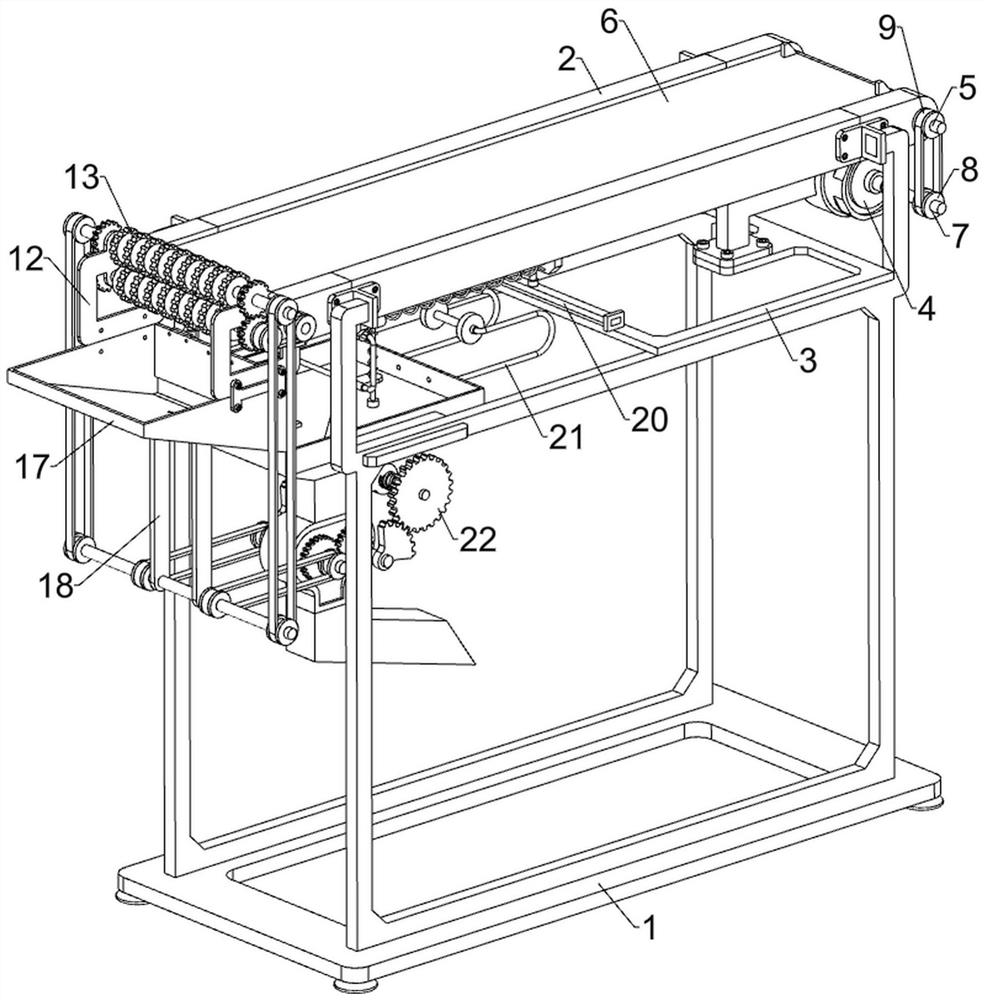

[0038] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of production equipment of easy-to-storage paint powder includes a support 1, a frame 2, a mounting plate 3, a double-axis motor 4, a first rotating shaft 5, a conveyor belt 6, a second rotating shaft 7, a first pulley 8, a second A flat belt 9, a protective case 10, a shielding case 11, a fixed frame 12, a crushing cylinder 13, a first gear 14, a second pulley 15, a second flat belt 16, a collecting assembly 17 and a finely crushing assembly 18, front and rear of the top of the support 1 Frames 2 are arranged on both sides, and a mounting plate 3 is provided on the right side of the upper part of the bracket 1. A biaxial motor 4 is arranged on the mounting plate 3. Two first rotating shafts 5 are rotatably arranged between the two frames 2. The first rotating shaft 5 is left-right symmetrical, and the two first rotating shafts 5 are covered with conveyor belts 6 through rollers. The upper part of...

Embodiment 2

[0041] Such as figure 1 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, on the basis of Embodiment 1, the collection assembly 17 includes a concentration frame 171, a guide sleeve 172, a first sliding rod 173, a first spring 174 and a blocking plate 175, and a Concentration frame 171, the right side of the concentration frame 171 is symmetrically provided with guide sleeves 172 front and back, and the first sliding rod 173 is slidably arranged on the two guide sleeves 172, between the bottom of the first sliding rod 173 and the bottom of the guide sleeve 172 on the same side. A first spring 174 is connected, and a blocking plate 175 is arranged between the bottom ends of the two first sliding rods 173 .

[0042] The fine crushing assembly 18 includes a first fixed plate 181, a rotating rod 182, a third pulley 183, a third flat belt 184, a collection frame 185, a storage hopper 186, a fine crushing cylinder 187, a second gear 188, a four...

Embodiment 3

[0045] Such as image 3 , Figure 4 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 and Figure 18 As shown, on the basis of Embodiment 2, a swing assembly 19 is also included. The swing assembly 19 includes a support frame 191, a swing plate 192 and a connecting rod 193. The right side of the concentration frame 171 is provided with a support frame 191. The support frame 191 A swinging plate 192 is arranged on the top to rotate, and a connecting rod 193 is arranged at the middle position of the top of the blocking plate 175, and the connecting rod 193 is slidingly connected with the lower part of the swinging plate 192 .

[0046] When the crushed paint in the concentration frame 171 reaches a certain amount, the staff presses the swing plate 192 to rotate downward, and the swing plate 192 rotates downward and pulls the blocking plate 175 through the connecting rod 193 to slide upward to open the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com