Underwater cleaning device and underwater robot system

A technology for cleaning devices and cleaning disks, which is applied to ship cleaning devices, underwater operation equipment, transportation and packaging, etc., can solve the problems of poor sealing performance of cleaning devices, easily damaged coatings or materials, and increased cage resistance. Underwater high pressure sealing effect, easy to use in loading operations, and achieve the effect of underwater zero buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

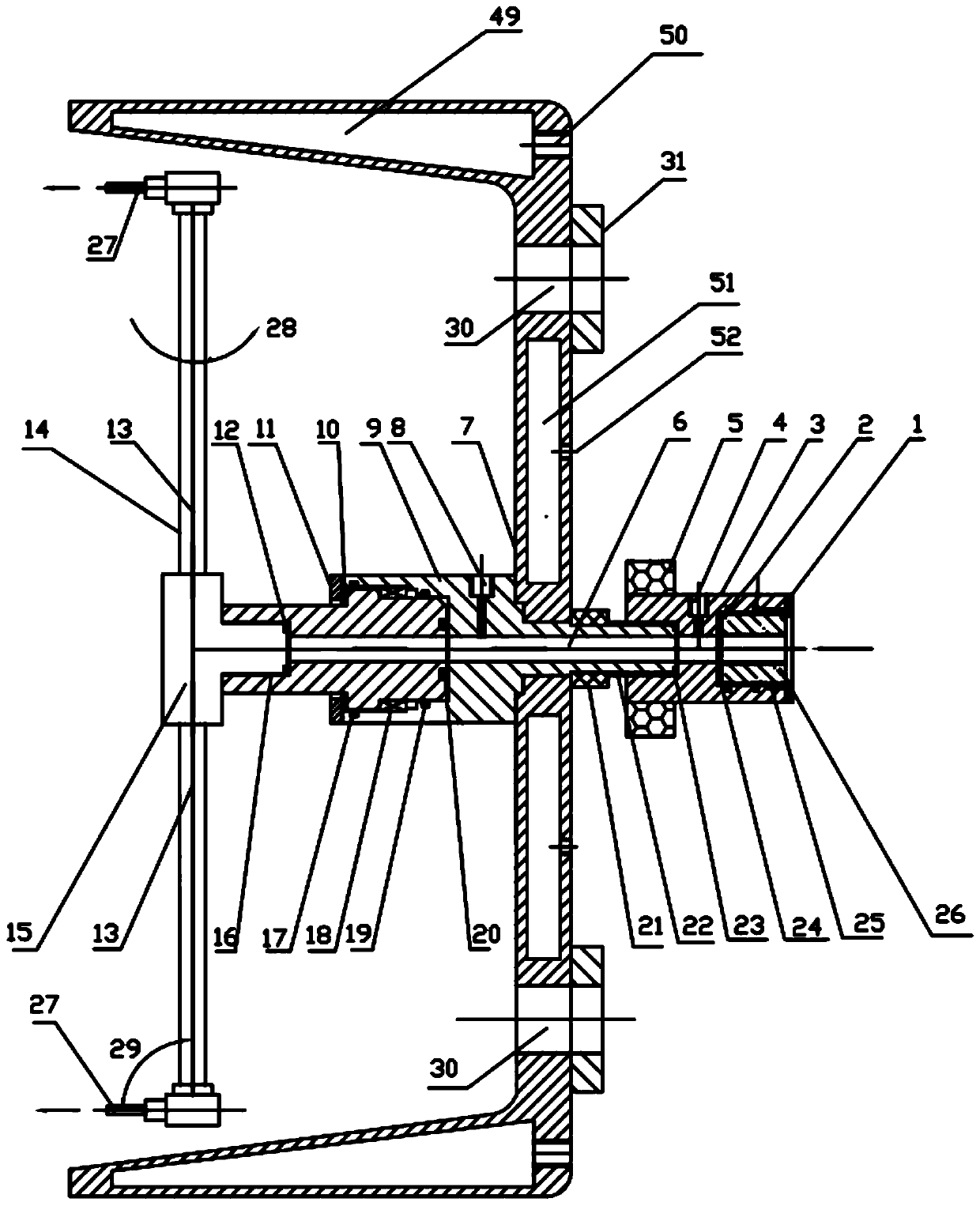

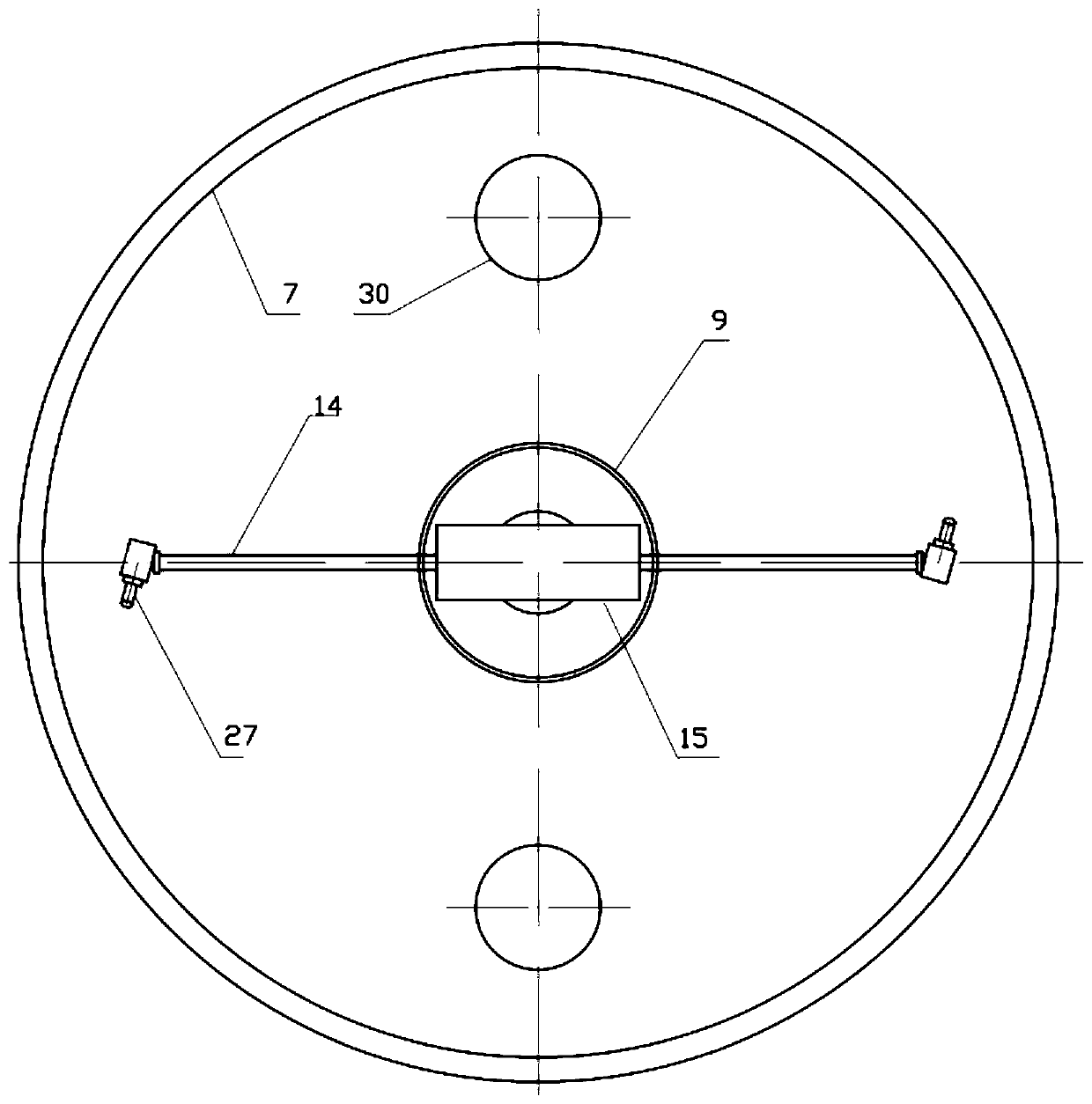

[0029] In one or more embodiments, an underwater cleaning device is disclosed, referring to figure 1 , including: cleaning device inner cavity 6, one end of the cleaning device inner cavity 6 is connected to the external high-pressure rubber hose through the first rotary joint 26, high-pressure water injection is provided through the external high-pressure rubber hose, and the high-pressure rubber hose is prevented from being rotated adaptively through the first rotary joint 26. The effect of bending and twisting on cleaning devices.

[0030] The other end of the inner cavity 6 of the cleaning device is connected to the cavitation injection rod through the second rotary joint 16; the rotation of the first rotary joint 26 and the second rotary joint 16 does not interfere with each other; the first rotary joint 26 is coaxially provided with a first fixed pipe , the second rotary joint 16 is coaxially provided with a second fixed pipe; the first fixed pipe and the second fixed pi...

Embodiment 2

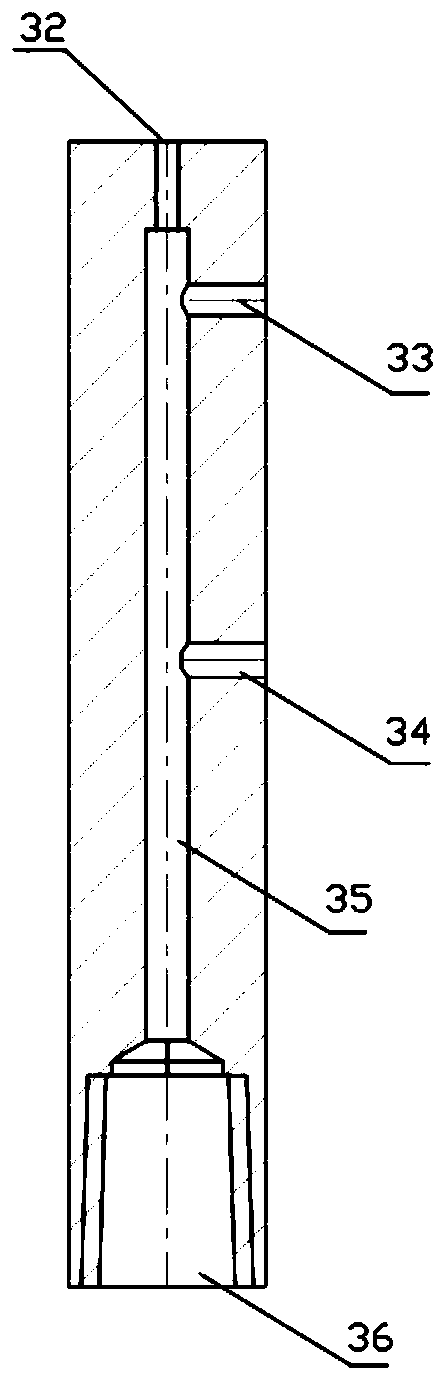

[0065] On the basis of Embodiment 1, this embodiment discloses an underwater cleaning robot system, which includes the underwater cleaning device described in Embodiment 1, wherein a loading fixture is connected to the fixed joint pipe 3 5. The actuator at the end of the robotic arm of the underwater robot can be connected through the loading fixture 5; the structure of the loading fixture 5 is as follows Figure 5 shown, including:

[0066]The two semicircular upper arc holes 42 and lower arc holes 47 on the lower clamp 45 and the upper clamp 44 clamp and fix the outer cylindrical surface of the fixed joint pipe 3 through the cooperation of the bolt 41 and the nut 43, thereby clamping and fixing the entire cleaning device. The distance between the upper fixture surface 48 and the lower fixture surface 46 can be adjusted according to the diameter of the fixed joint pipe 3; the loading fixture 5 can be installed at the end of the underwater mechanical arm, so the movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com