Special tooling drilling vessel for stripping and trimming

A drilling dish and tooling technology, applied in glass cutting devices, metal processing, manufacturing tools, etc., can solve the problems of increased labor costs, time costs, and low work efficiency, achieve broad market application prospects, improve processing efficiency, and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

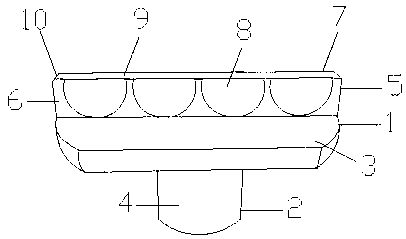

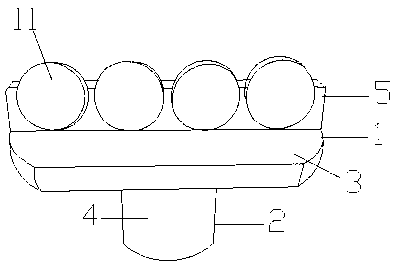

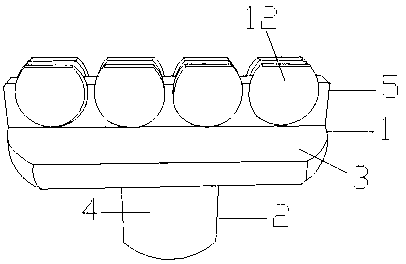

[0019] This embodiment provides a drilling dish for peeling and trimming special tooling, which includes a drilling dish body structure 1, and the drilling dish body structure 1 includes a drilling handle structure 2 and is arranged on the upper end of the drilling handle structure 2. Drilling dish platform surface 3, the outside of the drilling shank structure 2 is covered with a layer of wear-resistant cushion structure 4, the purpose of setting the wear-resistant cushion structure 4 is to increase the frictional force during contact , so that the clamping of the drilled dish structure 1 is more stable when in contact, the upper end of the drilled dish platform surface 3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com