Drying device for wind turbine blade mould

A technology of wind power generation blades and drying devices, which is applied in drying, drying machines, drying gas arrangement, etc., can solve problems such as low efficiency, prolonged drying time, and poor drying effect, and achieve friction-free and drying effects Good, fast heat drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

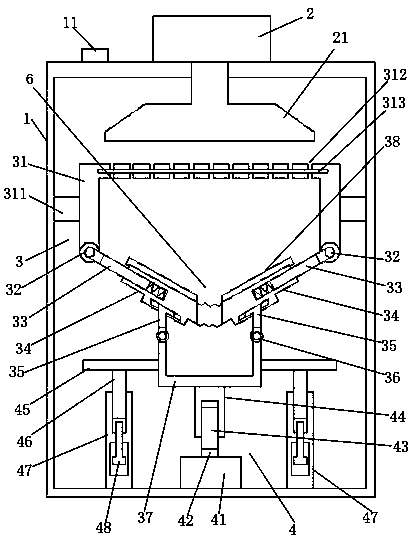

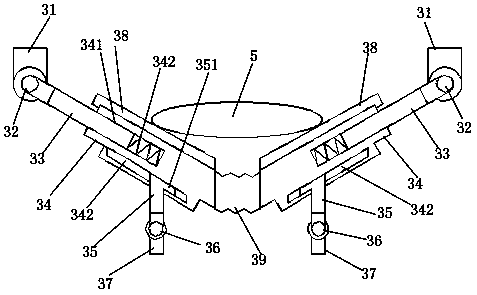

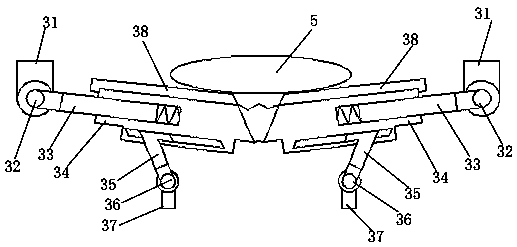

[0024] Such as Figures 1 to 5 As shown, a wind power blade mold drying device includes a drying bin body 1, a hot air blower 2, a supporting rotation mechanism 3, and a telescopic drive mechanism 4; a hot air blower 2 is installed outside the middle of the upper end of the drying bin body 1; The lower end of the hot air blower 2 is connected with a ventilation hood 21; the ventilation hood 21 is located at the inner upper end of the drying bin body 1; an exhaust port 11 is arranged above one end of the drying bin body 1; the supporting rotation mechanism 3 is installed inside the drying bin body 1; the supporting and rotating mechanism 3 includes a connecting cover 31, two upper rotating shafts 32, two rotating rods 33, two rotating telescopic plates 34, a flexible connecting plate 39, a connecting frame 37, two A rotating clamping rod 35 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com