Large integral positioning device

A positioning device and integrated technology, applied in the field of aviation assembly, can solve the problems of long positioning operation time of the positioner, affecting the quality and efficiency of product assembly, unstable front end shaking, etc., and achieve the effect of improving product quality and product assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

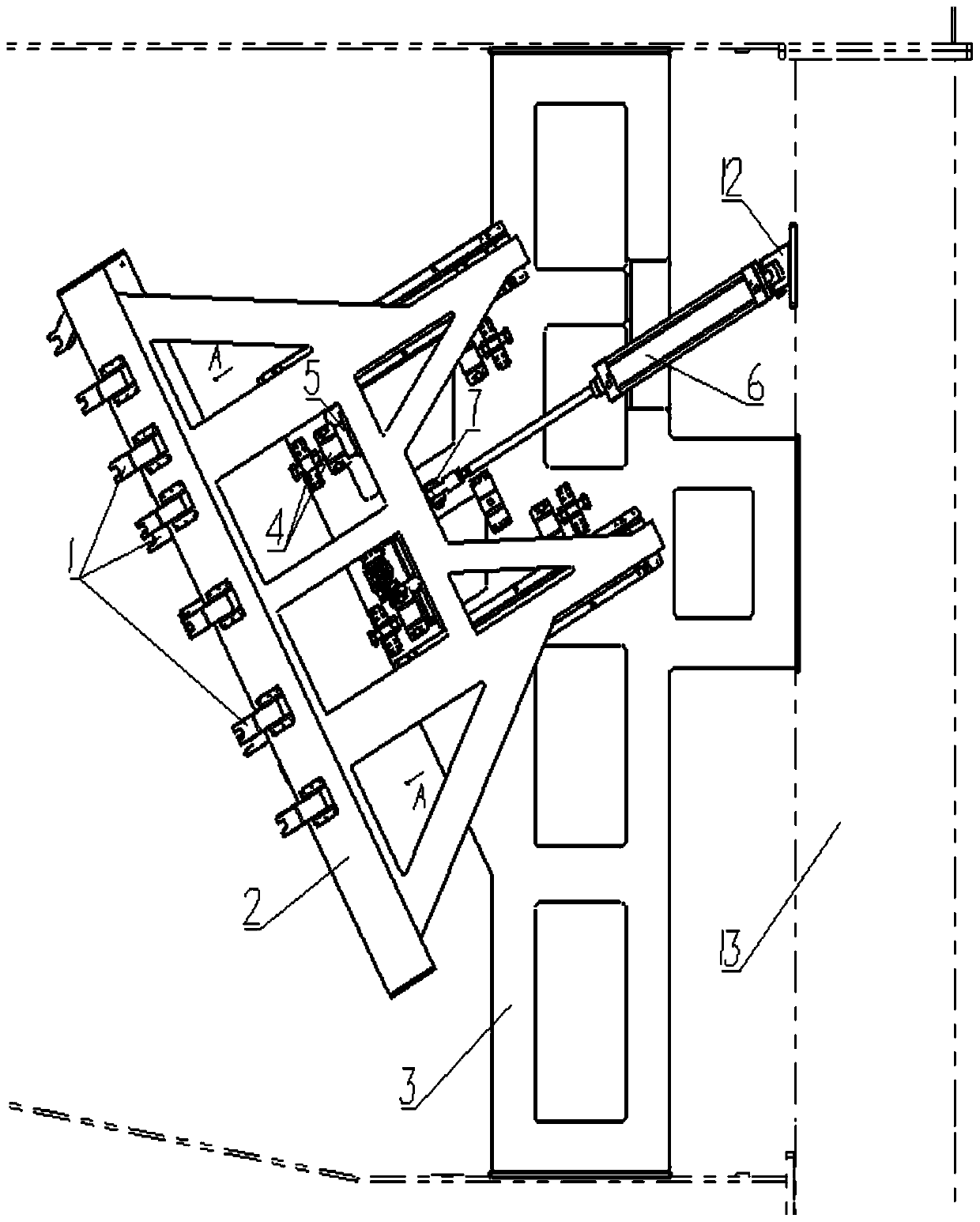

[0014] The present invention will be described in further detail below. A large integral fast and precise positioning device is proposed for the existing system. It is characterized in that the method steps for solving the above problems are as follows:

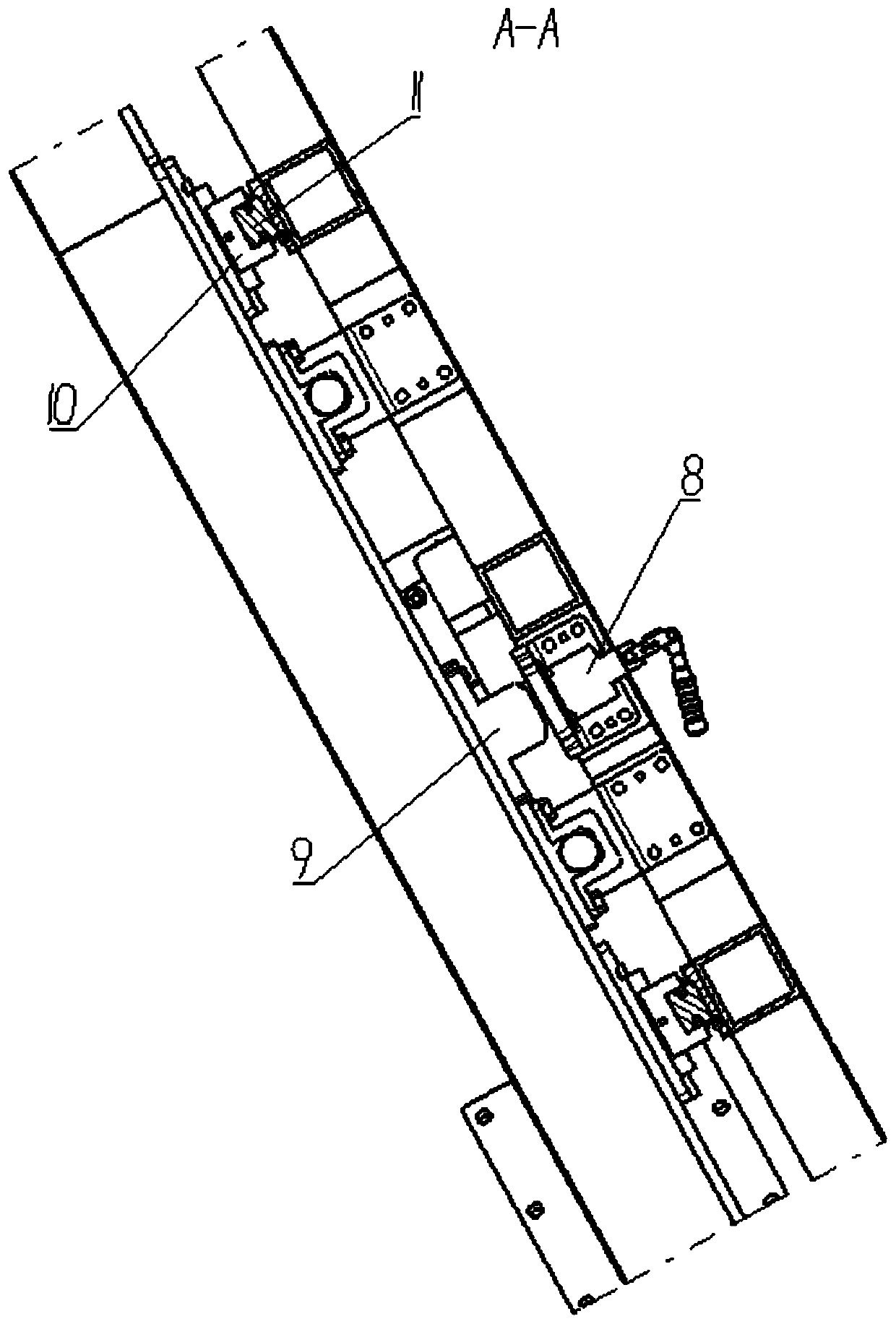

[0015] Design a set of locators 1 for locating products, and design a motion module 2 according to the spatial distribution of the locators 1. The locator 1 is fixedly connected with the motion module 2 through screws and cylindrical pins. Multiple sets of slide blocks 10 are arranged on the motion module 2, and the slide blocks 10 are connected with the motion module 2 by screws. A set of slide rails 11 is designed, and the slide rails 11 and the slider 10 are connected together. A support module 3 is designed, and the slide rail 11 is connected with the support module 3 by screws. A quick positioning assembly 8 is designed, and the quick positioning assembly 8 is fixedly connected with the motion module 2 through screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com