Automatic wine bottle labeling equipment

A wine bottle and labeling technology, applied in the directions of labeling, labeling machines, labels, etc., can solve the problems of increased labor, low labeling quality, and low labeling efficiency, and achieves the goal of improving work efficiency and labeling quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

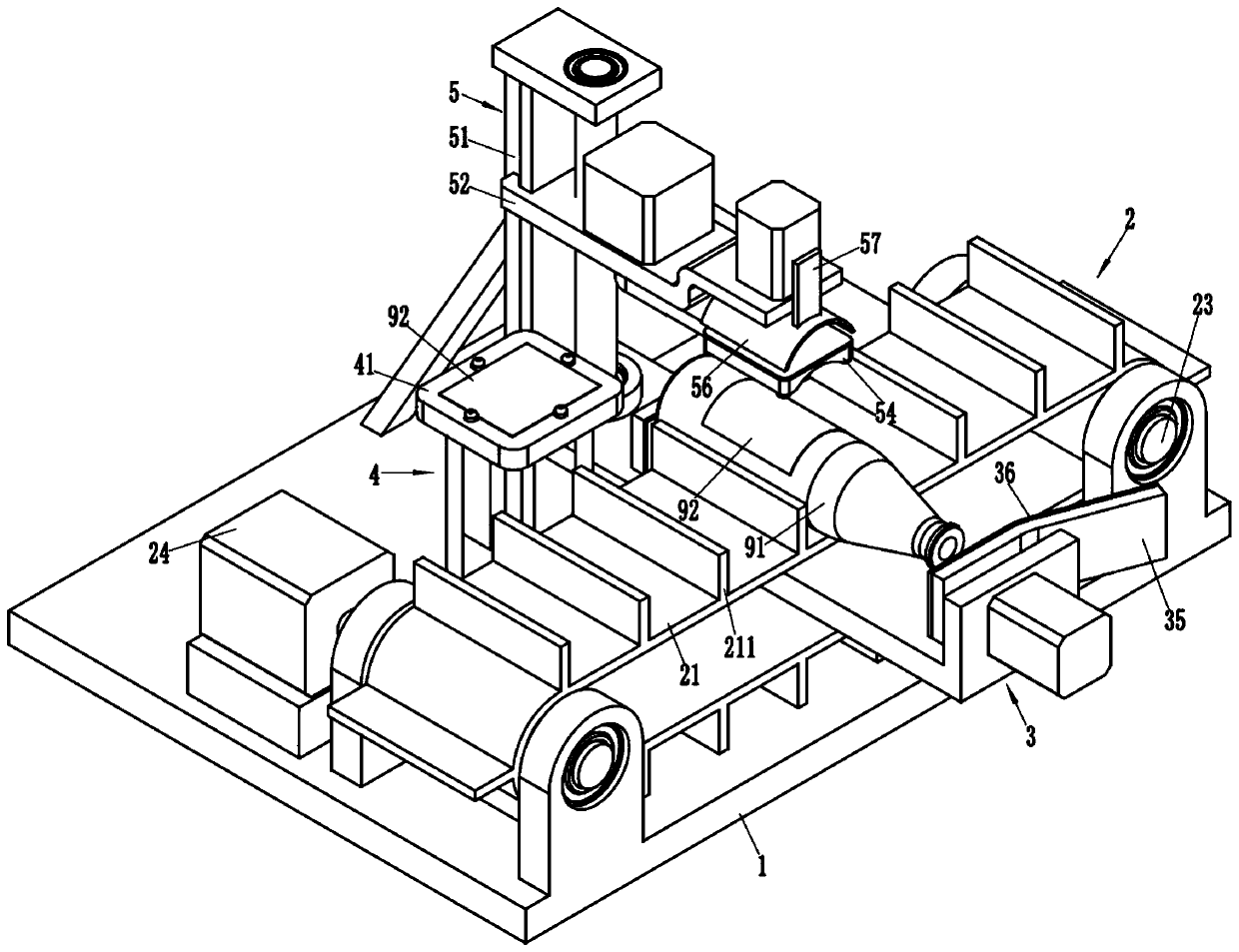

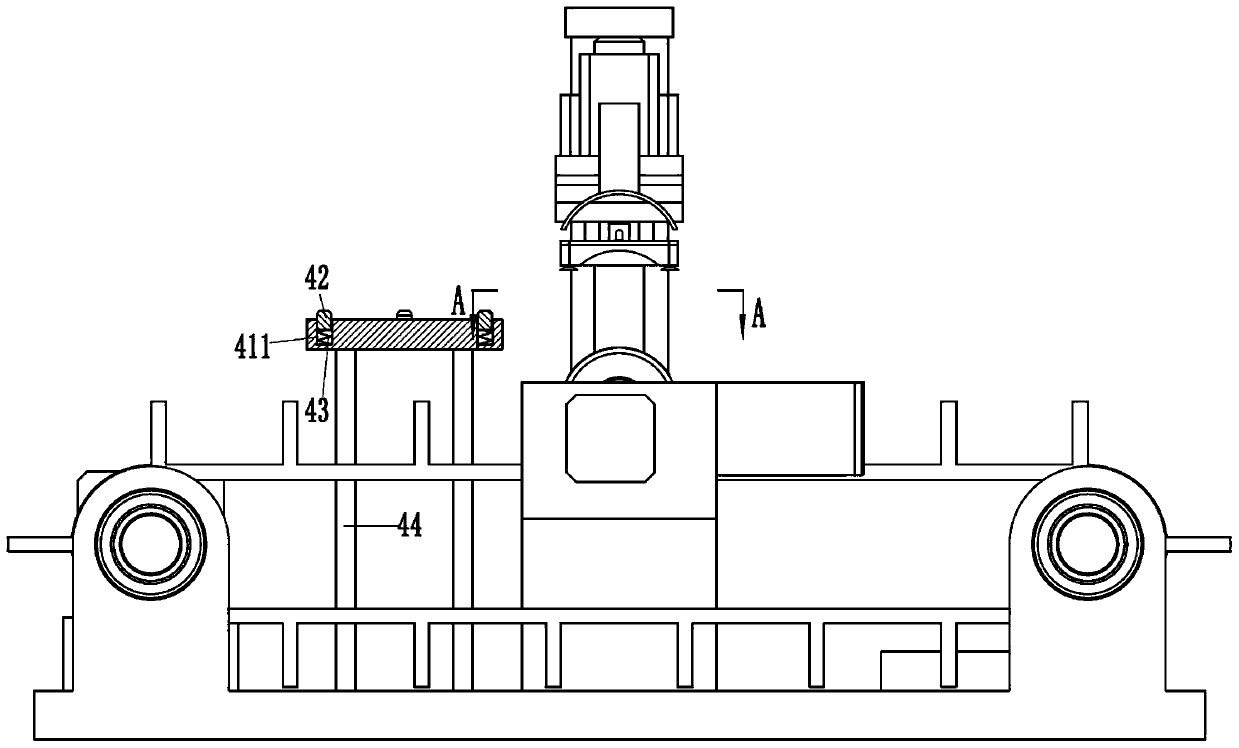

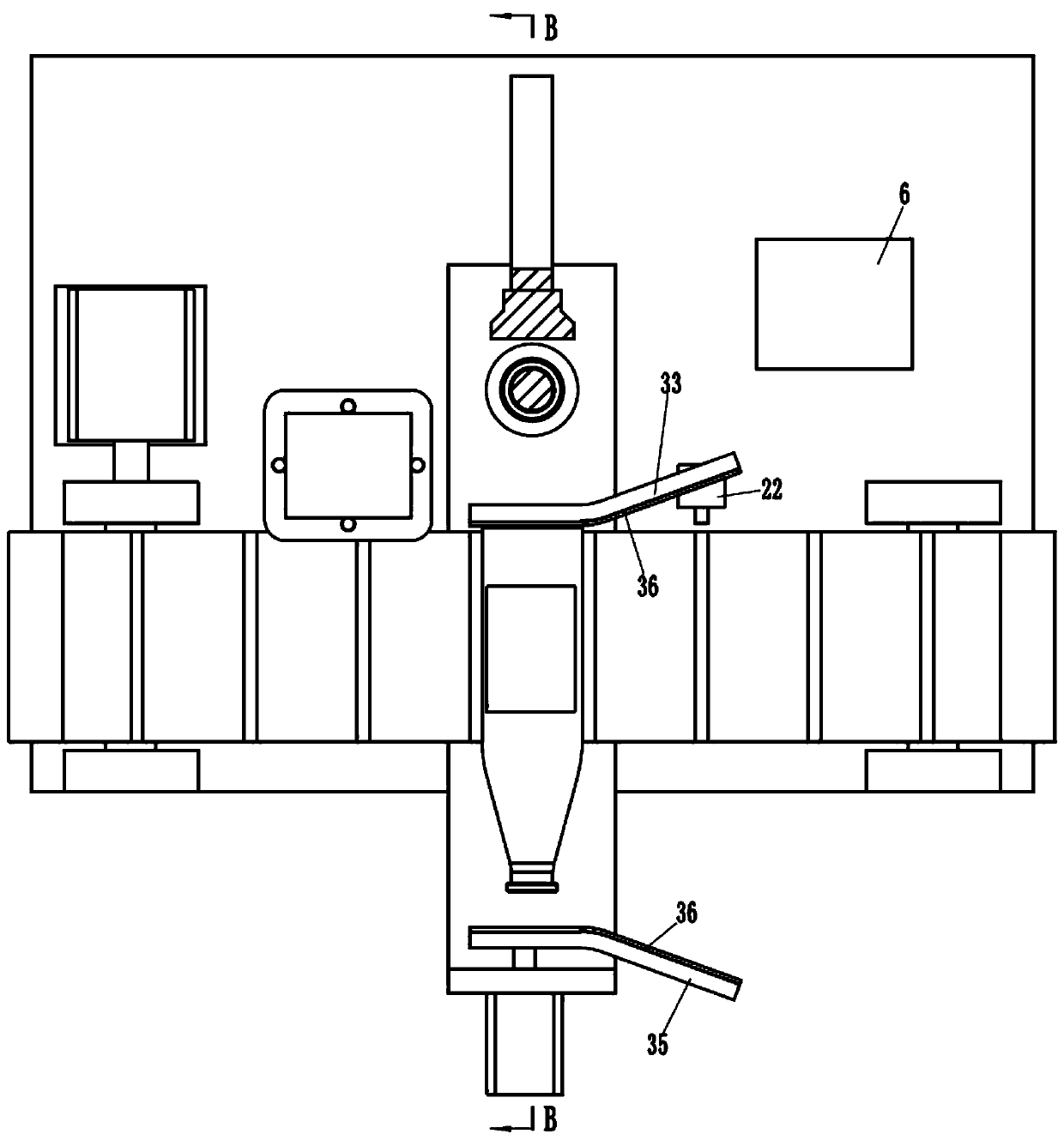

[0018] Examples, see e.g. Figure 1 to Figure 6 As shown, an automatic wine bottle labeling equipment includes a frame 1, and the frame 1 is provided with a wine bottle conveying mechanism 2, a wine bottle positioning mechanism 3, a label placement table 4 and a labeling mechanism 5. The wine bottle conveying mechanism 2 includes a

[0019] A square conveyor belt 21 and a sensor 22 are formed on the conveyor belt 21 with several linear and evenly distributed limiting plates 211, the wine bottle 91 is placed between the two limiting plates 211, the sensor 22 is facing the limiting plate 211, and the sensor 22 It is electrically connected with the control box 6 arranged on the frame 1; the wine bottle positioning mechanism 3 includes a base 31 fixed on the frame 1, a base plate 32 is fixed on the front side wall of the base 31, and the base plate 32 The rear end is fixed with a fixed guide splint 33, the base plate 32 passes through the front end of the conveyor belt 21 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com