Three-phase separation equipment for oil-containing silt (sand)

A three-phase separation, sediment technology, applied in immiscible liquid separation, liquid separation, separation methods and other directions, can solve the problems of polluted soil and water sources, environmental pollution, complex components and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

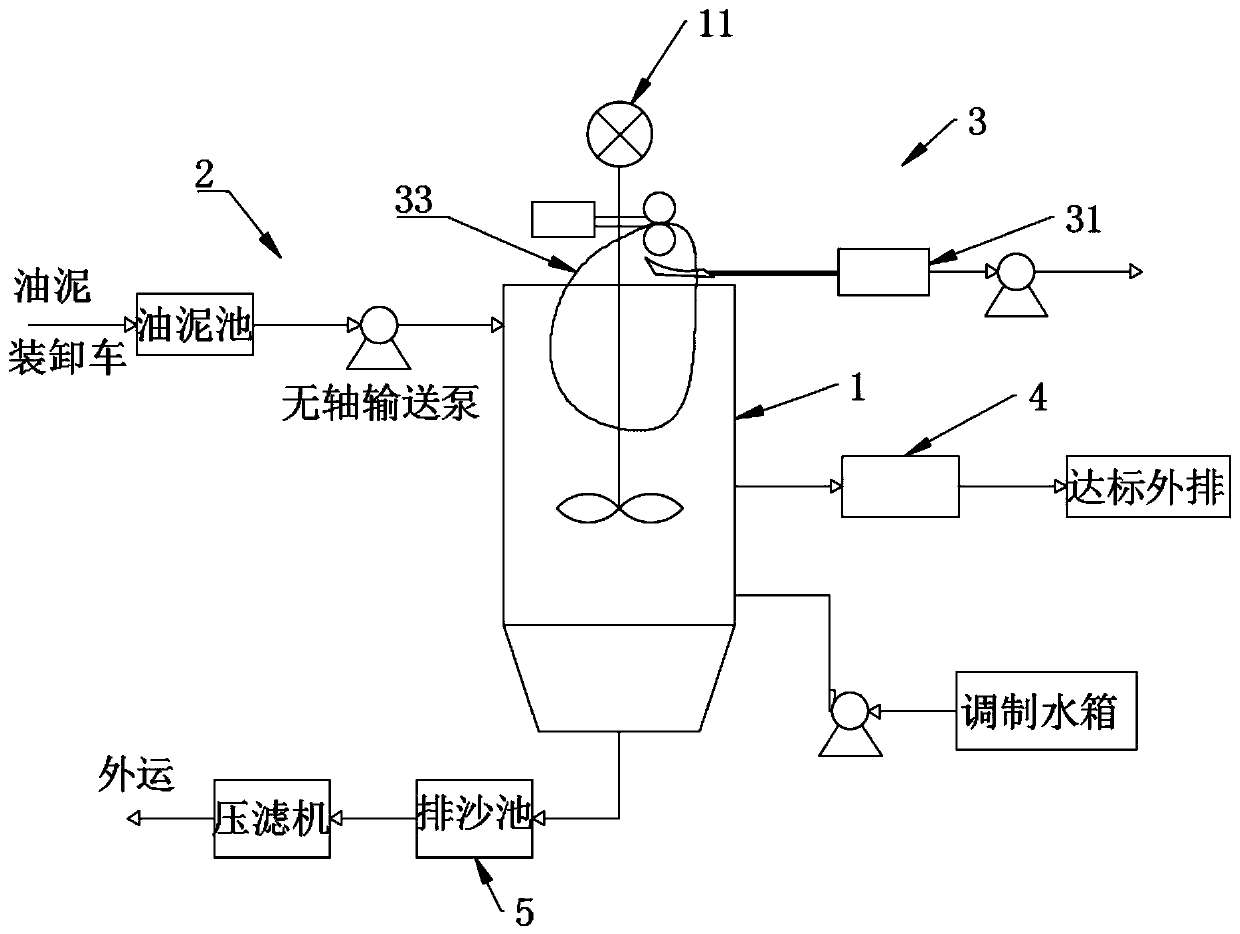

[0025] Embodiment: a kind of three-phase separation equipment of oily silt (sand), as figure 1 As shown, a stirring reaction tank 1 is included, and a rotatable stirrer 11 is arranged in the stirring reaction tank 1. A rotor pump or an auger conveying mechanism 2 for sending oily silt into the stirring reaction tank 1 is arranged on one side of the stirring reaction tank 1, and the other side A brewing water tank is provided to send the acid potion into the stirring reaction tank 1, the acid potion is 5%-10% hydrochloric acid, and the concentration of the acid solution is selected according to the oil content ratio in the oily sediment. An oil extraction mechanism 3 is arranged obliquely above the stirring reaction tank 1. The oil extraction mechanism 3 includes an oil tank 31, a gear pump and a sticky oil hose 33. Two meshing gears 32 are set above the stirring reaction tank 1, and the two meshing gears A flexible oily hose 33 is pierced between the gears 32, and a gear pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com