Multi-stage hot isostatic pressing method of Cu-containing cast Al-Si-Mg aluminum alloy castings

A technology of aluminum alloy casting and hot isostatic pressing, applied in the field of static pressing, can solve the problems of limited application and unpredictable performance, and achieve the effect of improving the degree of densification, mechanical properties and plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

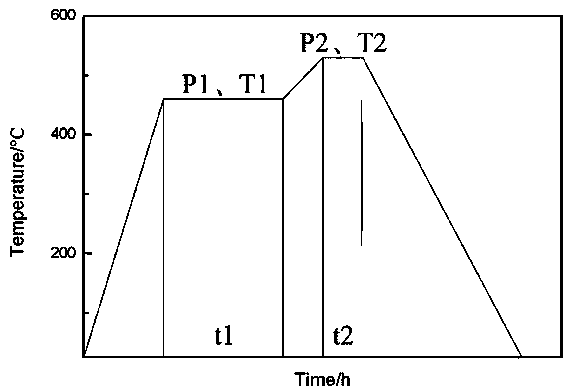

[0027] After the pouring of A336 and A354 alloy castings is completed, after cleaning, the main wall thickness is 40-70mm, and then the hot isostatic pressing process is used: the hot isostatic pressing process is divided into two processes, the first process pressure P 1 is 110MPa, temperature T 1 at 490°C, time t 1 is 1.5h, then enters the second process, the pressure P of the second process 2 is 110MPa, temperature T2 is 530℃, time t 2 for 30min. After the treatment is completed, the pressure is unloaded on the hot isostatic pressing furnace, and the casting is cooled to room temperature with the furnace, and then the casting is subjected to heat treatment and mechanical processing.

Embodiment 2

[0029] After the pouring of A318 and A332 alloy castings is completed, after cleaning, the main wall thickness is 20-40mm, and then the hot isostatic pressing process is used: the hot isostatic pressing process is divided into two processes, the first process pressure P 1 is 100MPa, temperature T 1 at 490°C, time t 1 is 1.5h, then enters the second process, the pressure P of the second process 2 is 100MPa, temperature T 2 at 530°C, time t 2 for 30min. After the treatment is completed, the pressure is unloaded on the hot isostatic pressing furnace, and the casting is cooled to room temperature with the furnace, and then the casting is subjected to heat treatment and mechanical processing.

Embodiment 3

[0031] After the pouring of A333 and A390 alloy castings is completed, after cleaning, the main wall thickness is less than 20mm, and then the hot isostatic pressing process is used: the hot isostatic pressing process is divided into two processes, the first process pressure P 1 90MPa, temperature T 1 at 460°C, time t 1is 1.5h, then enters the second process, the pressure P of the second process 2 is 100MPa, temperature T 2 at 530°C, time t 2 for 30min. After the treatment is completed, the pressure is unloaded on the hot isostatic pressing furnace, and the casting is cooled to room temperature with the furnace, and then the casting is subjected to heat treatment and mechanical processing.

[0032] The density, mechanical properties and elongation of the castings are all improved after the above hot isostatic pressing treatment. The density after hot isostatic pressing is 2.3% higher than that of castings without hot isostatic pressing, the mechanical properties after hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com