Polishing waste acid regeneration method

A waste acid and sulfuric acid technology, applied in chemical instruments and methods, ion exchange column/bed methods, special treatment targets, etc., can solve problems such as troublesome post-processing, and achieve the effects of easy operation, improved removal rate, and high economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The regeneration method of the polishing waste acid of the present embodiment comprises the following steps:

[0029] (1) Filled resin column

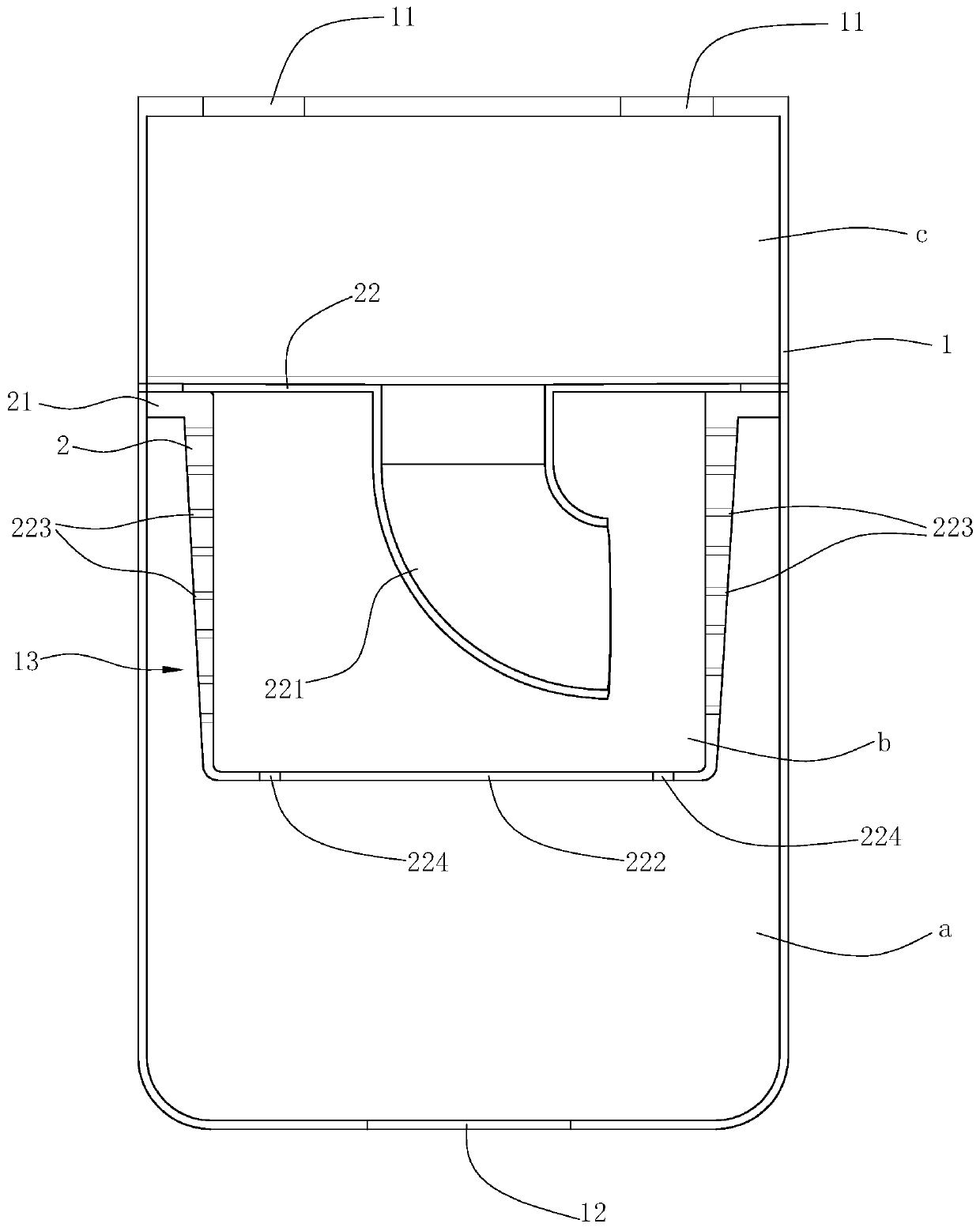

[0030] 800gYK-20 color-changing resin a, 1200gD001-CC type cation exchange resin b, 1000g001×4 gel-type strongly acidic styrene-based cation exchange resin c are filled in the glass column 1 successively from bottom to top; The liquid end and the lower end are the liquid outlet;

[0031] (2) Waste acid passes through resin column

[0032] 100g of waste acid with a mass fraction of aluminum ions of 1.5% is input from the liquid inlet and outlet of the glass column 1, and the acid solution flowing out from the resin column has a mass fraction of aluminum ions of 0.06%, and the removal rate of aluminum ions is 96%;

[0033] (3) Compounding of polishing acid

[0034] Add nitric acid and sulfuric acid to the acid solution after the resin column treatment, the total addition of nitric acid and sulfuric acid is 5g (sulfuric acid: ni...

Embodiment 2

[0042] The regeneration method of the polishing waste acid of the present embodiment comprises the following steps:

[0043] (1) Filled resin column

[0044] In the glass column 1, 700gYK-20 color-changing resin a, 2000gD001-CC type cation exchange resin b, 1000g001×4 gel type strongly acidic styrene-based cation exchange resin c are filled successively from bottom to top; The liquid end and the lower end are the liquid outlet;

[0045] (2) Waste acid passes through resin column

[0046] 80g of waste acid with a mass fraction of aluminum ions of 3% is input from the liquid inlet and output of the glass column 1; the mass fraction of aluminum ions flowing out from the resin column is 0.03%, and the removal rate of aluminum ions is 98%;

[0047] (3) Compounding of polishing acid

[0048] Add nitric acid and sulfuric acid to the acid solution after the resin column treatment, the total addition of nitric acid and sulfuric acid is 7g (sulfuric acid: nitric acid=2:1) to obtain...

Embodiment 3

[0052] The regeneration method of the polishing waste acid of the present embodiment comprises the following steps:

[0053] (1) Filled resin column

[0054] In the glass column 1, 500gYK-20 color-changing resin a, 1300gD001-CC type cation exchange resin b, 1000g001×4 gel-type strongly acidic styrene-based cation exchange resin c are filled successively from bottom to top; The liquid end and the lower end are the liquid outlet;

[0055] (2) Waste acid passes through resin column

[0056] 80g of waste acid with a mass fraction of aluminum ions of 0.5% is input from the liquid inlet and outlet of the glass column 1, and the acid solution flowing out from the resin column has a mass fraction of aluminum ions of 0.02%, and the removal rate of aluminum ions is 98%;

[0057] (3) Compounding of polishing acid

[0058] Add nitric acid and sulfuric acid in the acid solution after resin column treatment, the total addition of nitric acid and sulfuric acid is 2g (sulfuric acid: nitric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com