High-vacuum degree screw type vacuum pump

A high-vacuum, screw-type technology, applied in the direction of rotary piston pumps, pumps, rotary piston/swing piston pump components, etc., can solve the problems of screw wear, affecting the vacuum degree of the pump body, affecting the work of the pump body, etc. , to achieve the effect of preventing wear and ensuring high vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples.

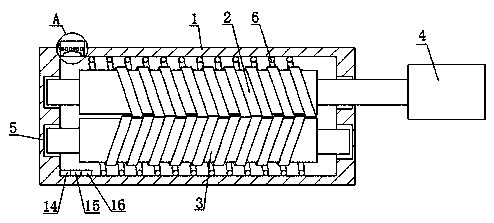

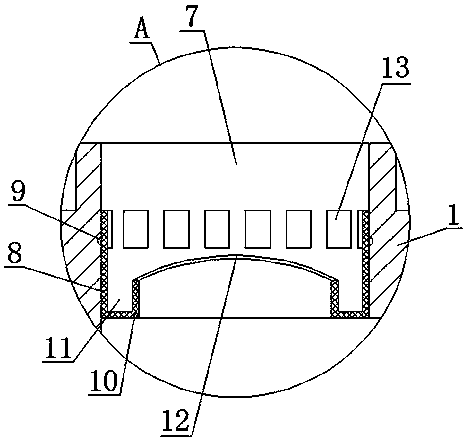

[0013] refer to Figure 1-2 , this embodiment provides a high-vacuum screw type vacuum pump, including a pump casing 1, a driving screw 2, a driven screw 3, a motor 4 and a bearing seat 5, and the pump casing 1 is horizontally provided with two engaging driving screws 2 And the driven screw 3, the motor 4 connected with the driving screw 2 is provided outside the pump casing 1, and the screw teeth with the opposite direction of rotation are provided on the driving screw 2 and the driven screw 3; the inside of the pump casing 1 is provided with The bearing housing 5 connecting the two ends of the active screw 2 and the driven screw 3; the inner wall of the pump casing 1 is installed with a cooling pipe 6 through a clamp, and the cooling pipe 6 is injected with cooling liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com