Output power-increased electric heating device

An electric heating device and output power technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of not considering the heat-resistant limit temperature of heating tube materials, short service life of products, and safety. To achieve the effect of compact structure, reduced material consumption, and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

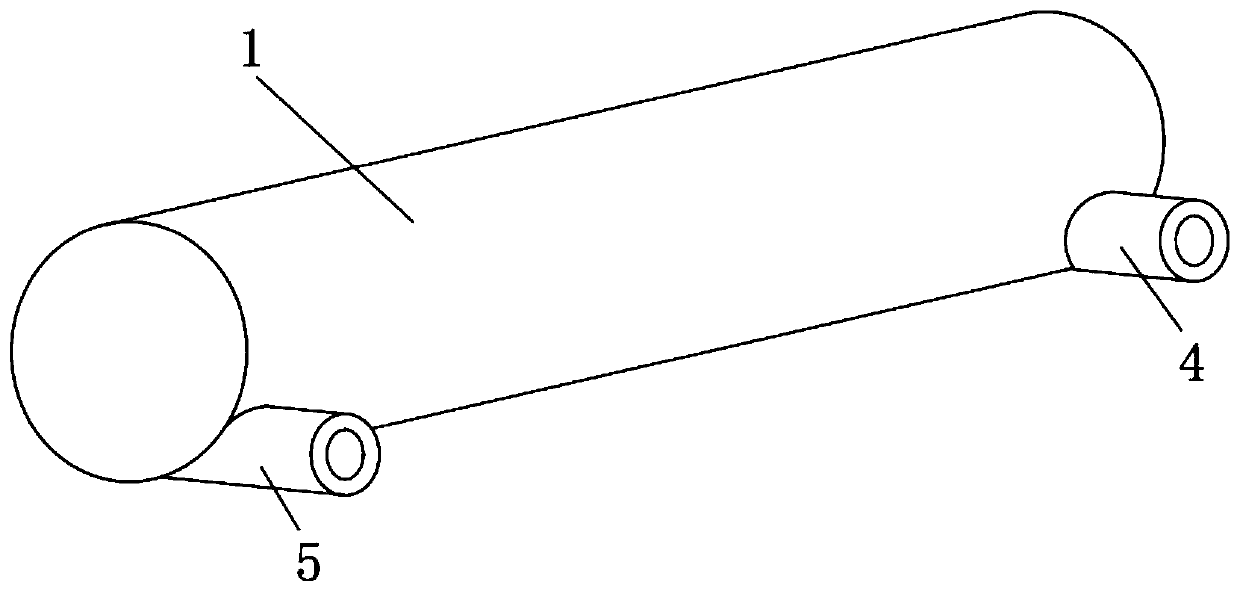

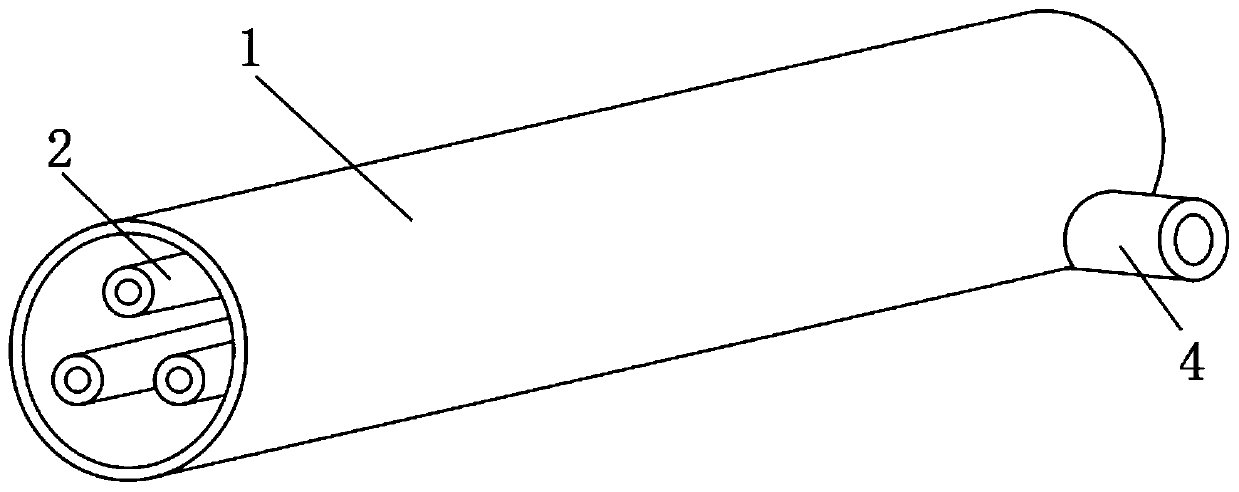

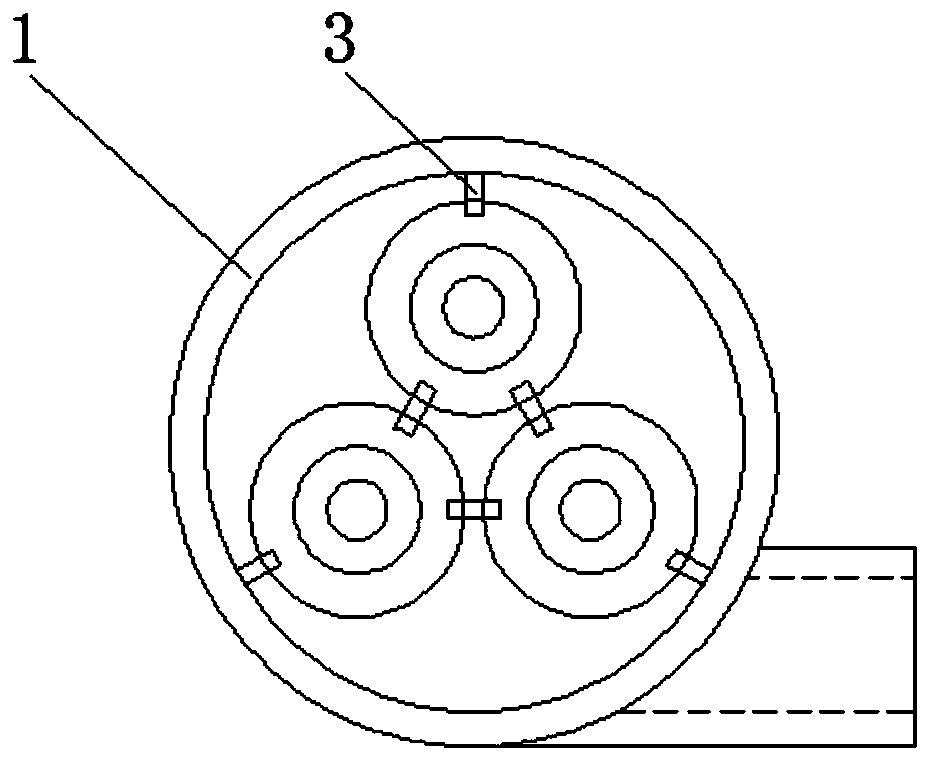

[0027] Such as Figure 1 to Figure 5 As shown, an electric heating device with increased output power includes a housing 1, a heating tube 2, a support 3, an outlet 4 and an inlet 5; 4 and the cylinder structure of the inlet 5, and the two ends of the cylinder are closed, three heating tubes 2 are installed in the shell 1, arranged in a character shape, the heating tubes 2 are equal inner diameter heating tubes 201, and the outer diameters of the heating tubes 2 are non-equal Diameter setting, the outer diameter of the heating tube 2 at the inlet 5 is smaller than the outer diameter of the heating tube 2 at the outlet 4; there is a gap between the heating tube 2 end and the shell 1 end, and the heating tube 2 and the shell 1 The space between the heating pipes 2 and the adjacent heating pipes 2 are all fixed by the support 3, and the support 3 is located in the middle of the heating pipe 2. The specific number of heating tubes 2 is adjusted according to actual needs. When the...

Embodiment 2

[0032] Such as Figure 6 and Figure 7 As shown, the difference between embodiment 2 and embodiment 1 is that the heating tube 2 in embodiment 2 is a heating tube 202 of equal medium diameter, and the inner diameter of the heating tube 2 at the 5 end of the inflow port is greater than the inner diameter of the heating tube 2 at the 4 end of the outlet port, and the inflow The outer diameter of the heating tube 2 at the port 5 end is smaller than the outer diameter of the heating tube 2 at the outlet port 4 end.

[0033] In the design of the heating tube 202 with equal medium diameter, the inner diameter of the heating tube 2 gradually decreases and the outer diameter gradually increases, so that the cross-sectional area of the heating tube 2 increases rapidly. Under the condition of the heating tubes 2 of the same quality, to achieve the same heating effect, the axial dimension of the heating tube 202 with the same medium diameter is smaller. When there are constraints on ...

Embodiment 3

[0035] Such as Figure 8 and Figure 9 As shown, the difference between embodiment 3 and embodiment 1 is that the heating tube 2 in embodiment 3 is a heating tube 203 with an equal outer diameter, the outer diameter of the heating tube 2 is set at an equal diameter, and the inner diameter of the heating tube 2 at the 5 ends of the inlet port is larger than that of the outlet. The inner diameter of the heating tube 2 at the 4 ends of the orifice.

[0036] In the design of the constant outer diameter heating tube 203 , the outer diameter of the heating tube 2 is kept constant, and the cross-sectional area of the tube is gradually increased by reducing the inner diameter of the heating tube 2 . When there is a requirement for the radial size of the heater or the spacing between the heating tubes 2, the heating tubes 203 with equal outer diameters can be selected to obtain better results. As the cross-sectional area of the heating tube 2 gradually increases, the flow area of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com