Turbine movable blades cooling structure of marine gas turbine

A gas turbine and cooling structure technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem that the high temperature resistance cannot meet the use requirements of turbine blades, achieve safe and long-life use, reduce manufacturing costs, and make manufacturing difficult low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the application of the present invention will be further described:

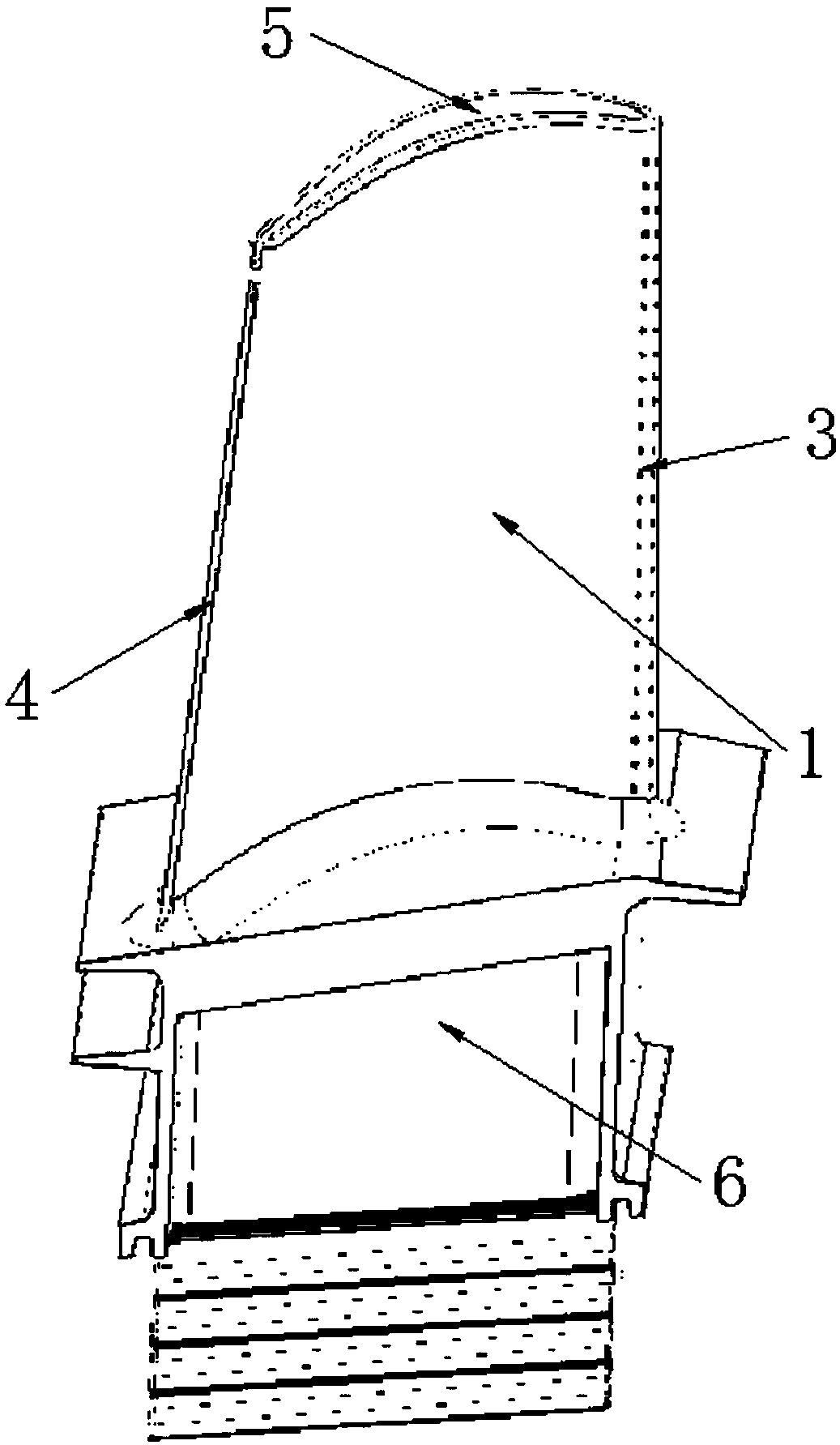

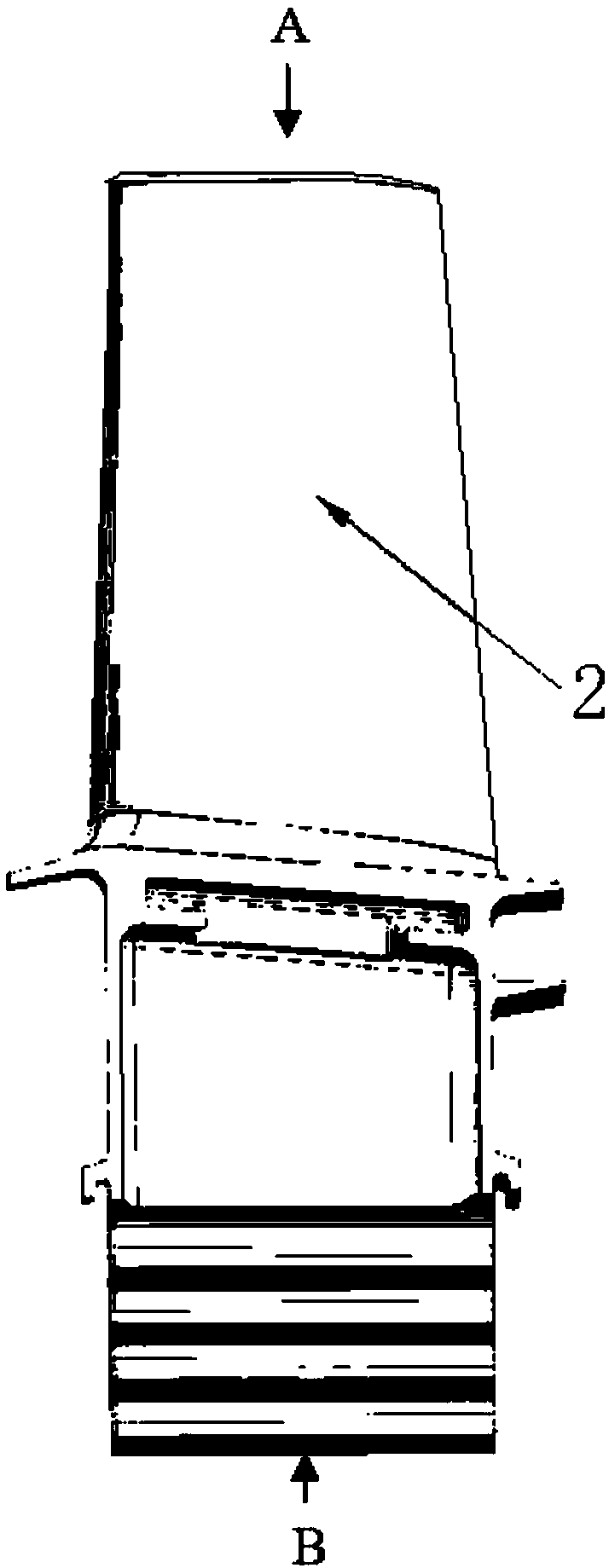

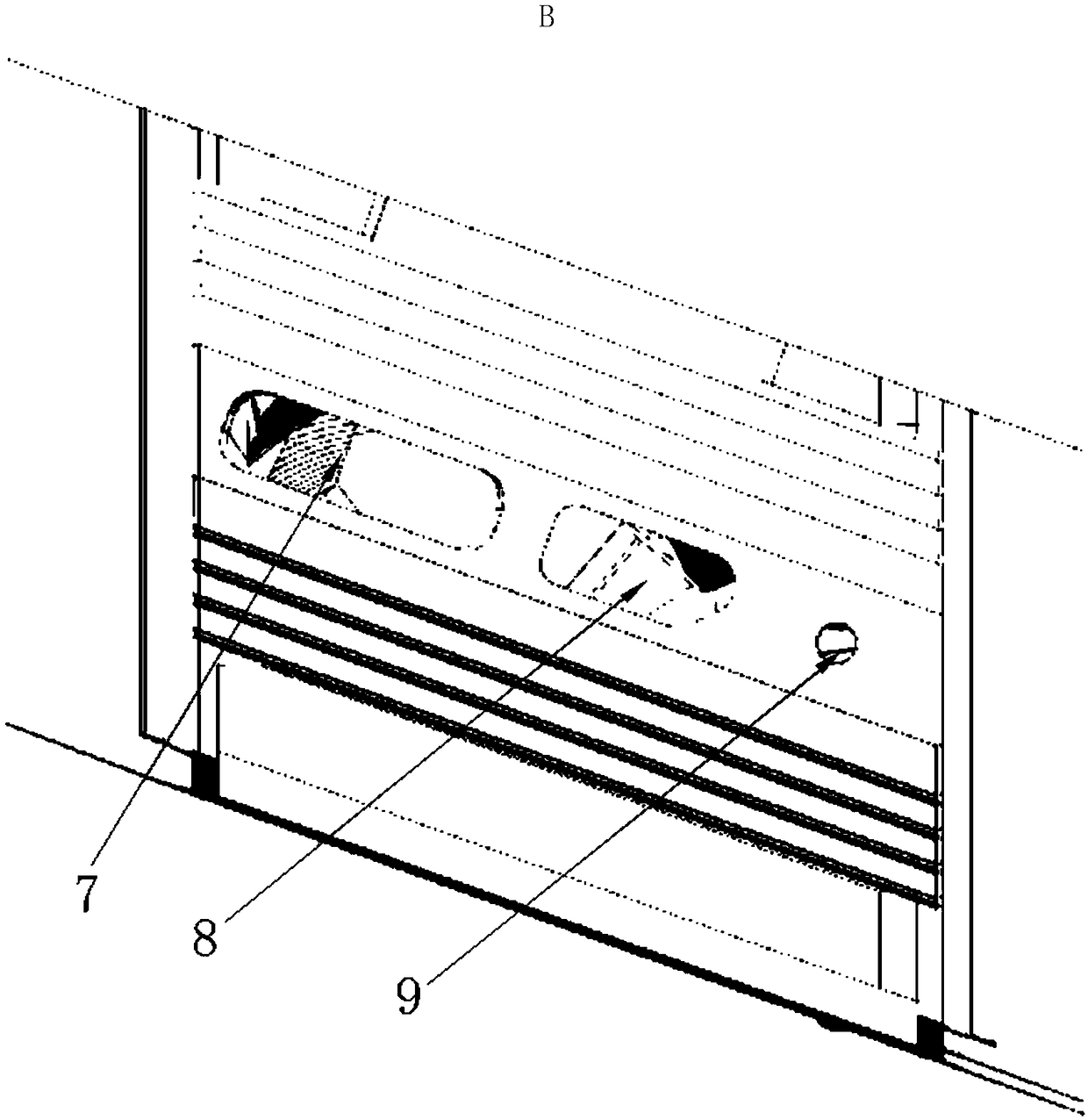

[0018] see Figure 1-Figure 4 As shown, a cooling structure of a marine gas turbine turbine blade in this embodiment includes a blade root 6, an airfoil pressure surface 1, an airfoil suction surface 2, a blade leading edge 3, and a blade trailing edge 4; the top of the blade has an H shape Groove 5, the front part of the blade body is provided with a front ribbed serpentine cooling channel 11, the air film hole 12 communicating with the front part ribbed serpentine cooling channel 11 is arranged at 3 places on the leading edge of the blade, and the middle part of the blade body is provided with a middle belt The ribbed serpentine cooling channel 13, the spoiler column cooling channel 14 is provided at the blade trailing edge 4, the ribbed serpentine cooling channel 13 in the middle is connected with the spoiler column cooling channel 14, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com