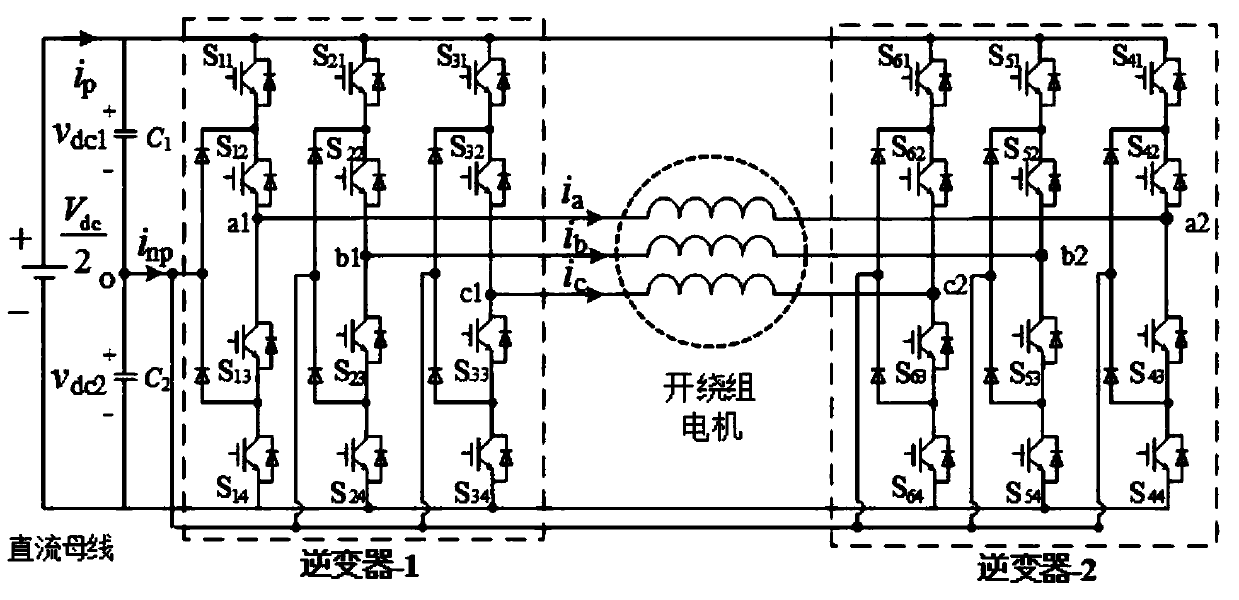

Double-three-level inverter open winding motor model control method

A three-level inverter and motor model technology, which is applied in the direction of motor generator control, electronic commutation motor control, AC motor control, etc., can solve the problem of dual two-level output voltage with less vectors, fewer control targets, and increased system Issues such as cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention without constituting a limitation on the rights of the present invention.

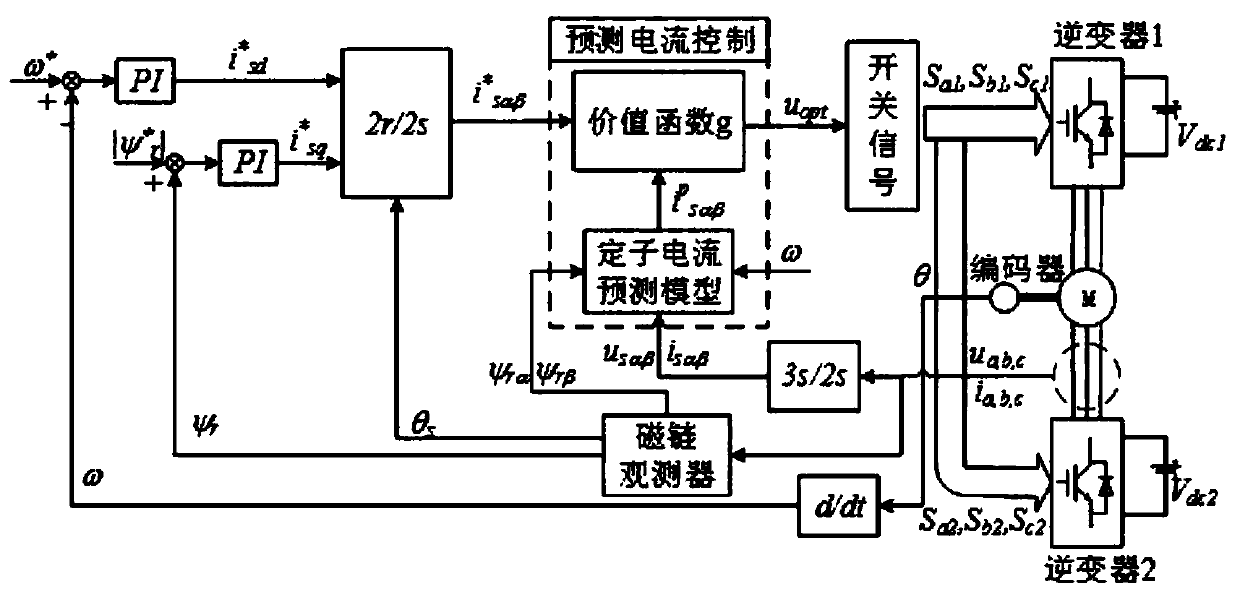

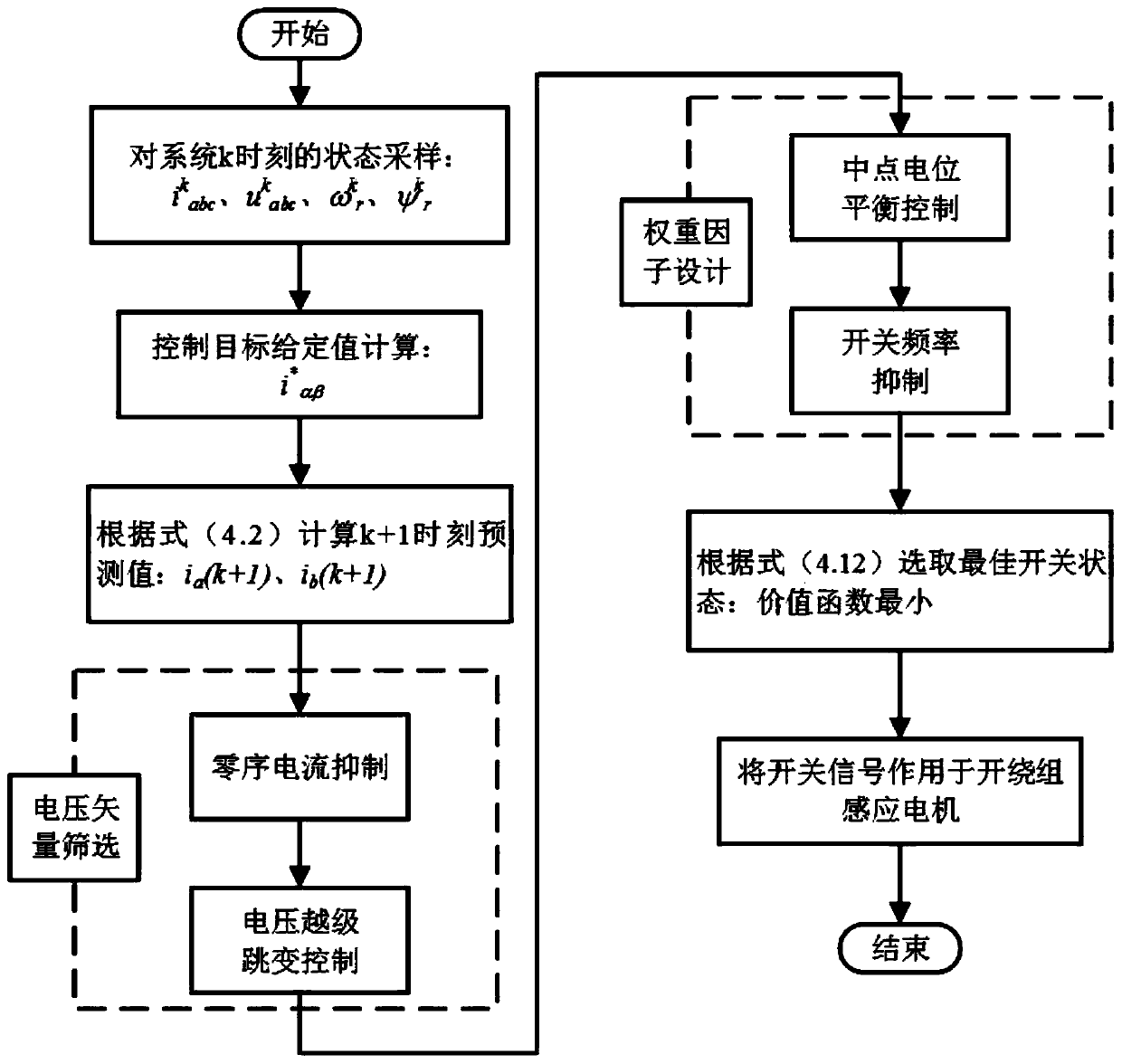

[0065] refer to Figure 1-3 , a dual three-level inverter open-winding motor model control method, the method includes the following steps,

[0066] (1) For the voltage at the kth moment electric current Rotating speed and the flux signal Sampling observation, given signal by flux linkage Estimate the flux linkage value ψ with the flux observer r Make a difference, and get the given value of the d-axis component of the stator current after passing through the PI regulator Through the given speed ω * Compared with the speed ω actually measured by the encoder, the given value of the stator current q component It can be obtained after adjustment by the PI regulator;

[0067...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com