Tool change method

A cutter body and cutting tool technology, applied to milling cutters, milling machine equipment, grinding machines, etc., can solve the problems of shorter overall length of cutters, discrepancy of milling cutters, reduction of milling cutter specifications, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

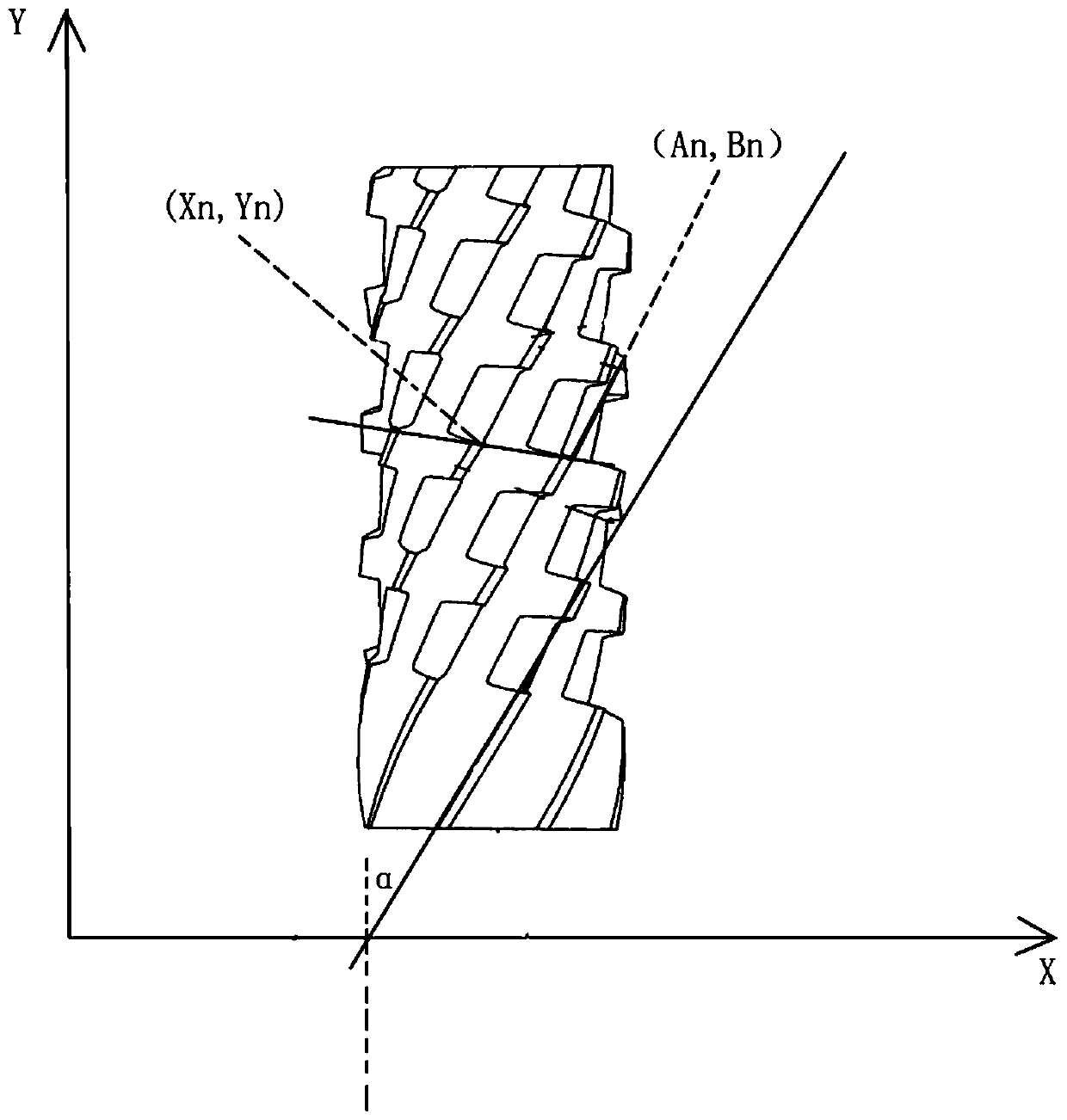

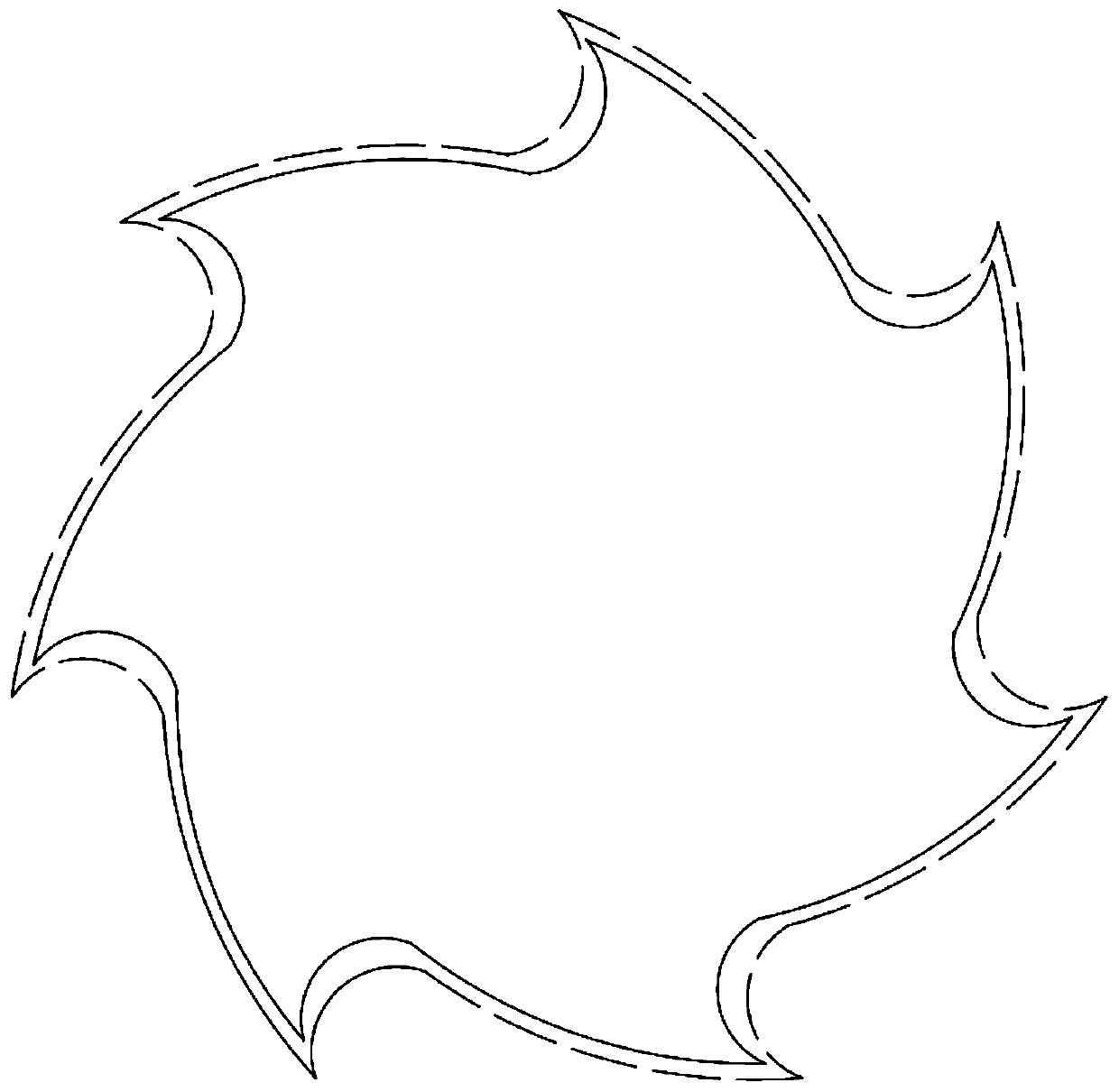

[0017] Such as figure 1 As shown, the present invention proposes a kind of knife changing method, comprises the following steps:

[0018] S1: Establish XY axis coordinate information, and obtain the groove position information of the tool to be modified;

[0019] In this step, it can be obtained through the CCD camera. Specifically, after fixing the recovered old tool on the fixture, turn the tool to the side where the position is relatively clear and complete, and obtain the image information through the CCD camera installed on the upper part. When working, usually only 80% of the length of the milling cutter is used, and the end of the shank is not used, so the detection end is an accurate starting position, such as figure 1 As shown, the blade including the cutting groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com