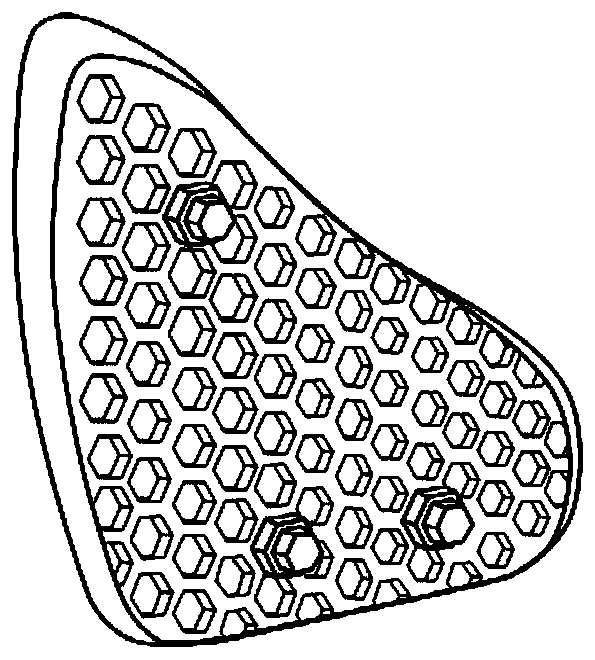

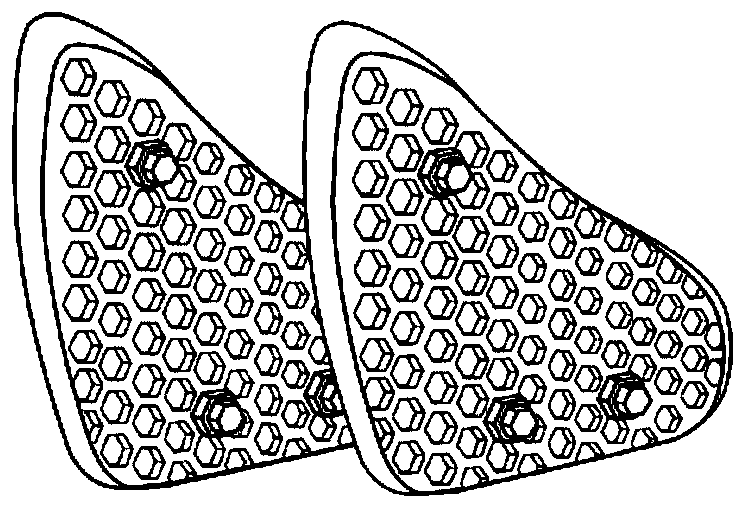

Assembled chair of honeycomb structure

A technology of honeycomb structure and assembled chairs, which is applied in the field of 3D printing, can solve the problems of high production cost, long production cycle, and low production efficiency of 3D printing, achieve convenient printing modification, improve the force strength, and save printing materials and printing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following describes several preferred embodiments of the present invention with reference to the accompanying drawings, so as to make the technical content clearer and easier to understand. The present invention can be embodied in many different forms of embodiments, and the protection scope of the present invention is not limited to the embodiments mentioned herein.

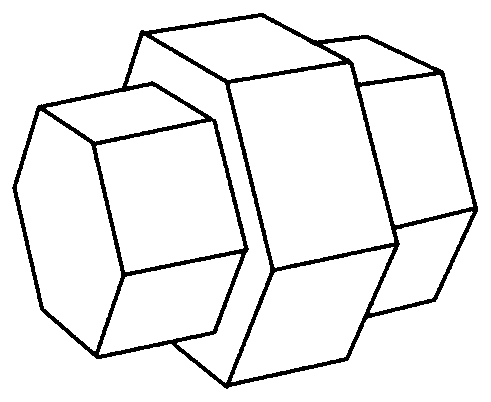

[0036] like Figure 1-3 As shown, on the one hand, the hollow structure can strengthen the stressed structure, so that each individual structure is not easily deformed under stress, and at the same time, compared with the fully filled structure, it can save printing materials and printing time. The hexagonal shape is relatively beautiful and stable, but the hollow structure is not limited to hexagonal shape, it can be triangular, pentagonal or other shapes. Each of the two slices has a positioning structure that cooperates with each other. When the bottom surface of the slice is aligned, the two slic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com