VOC-free coating liquid composition for image formation

A technology of coating liquid and composition, applied in the direction of coating, etc., can solve the problems of accidents, release of dangerous VOC substances, fire, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

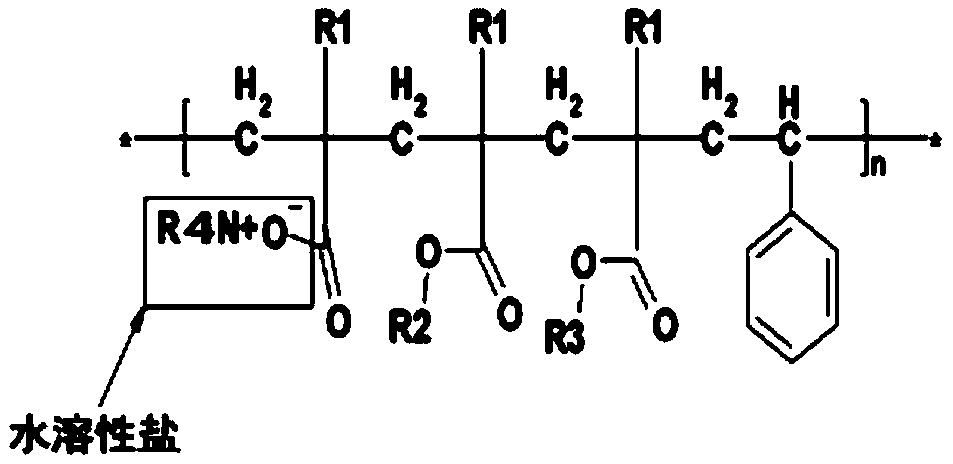

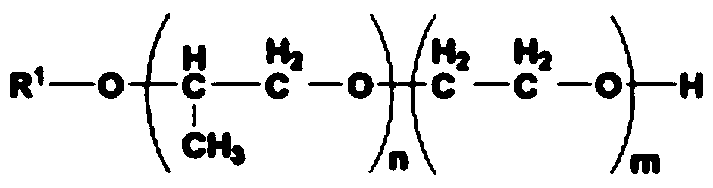

[0042] 1. The preparation method of coating liquid composition (comparative example, embodiment same, common)

[0043] Put the resin and liquid raw materials into the cylindrical paint production container, use a dissolver capable of high-speed dispersion to stir evenly at 500-1000RPM for 30 minutes, then put silicon oxide and hollow nano-titanium oxide in sequence , and disperse and stir at a high speed of 1200-1700 RPM for 2 hours, thereby preparing a VOC-free coating liquid composition for image formation.

[0044] 2. Substrate: glass plate Size: 450mm*600mm, thickness 3mm

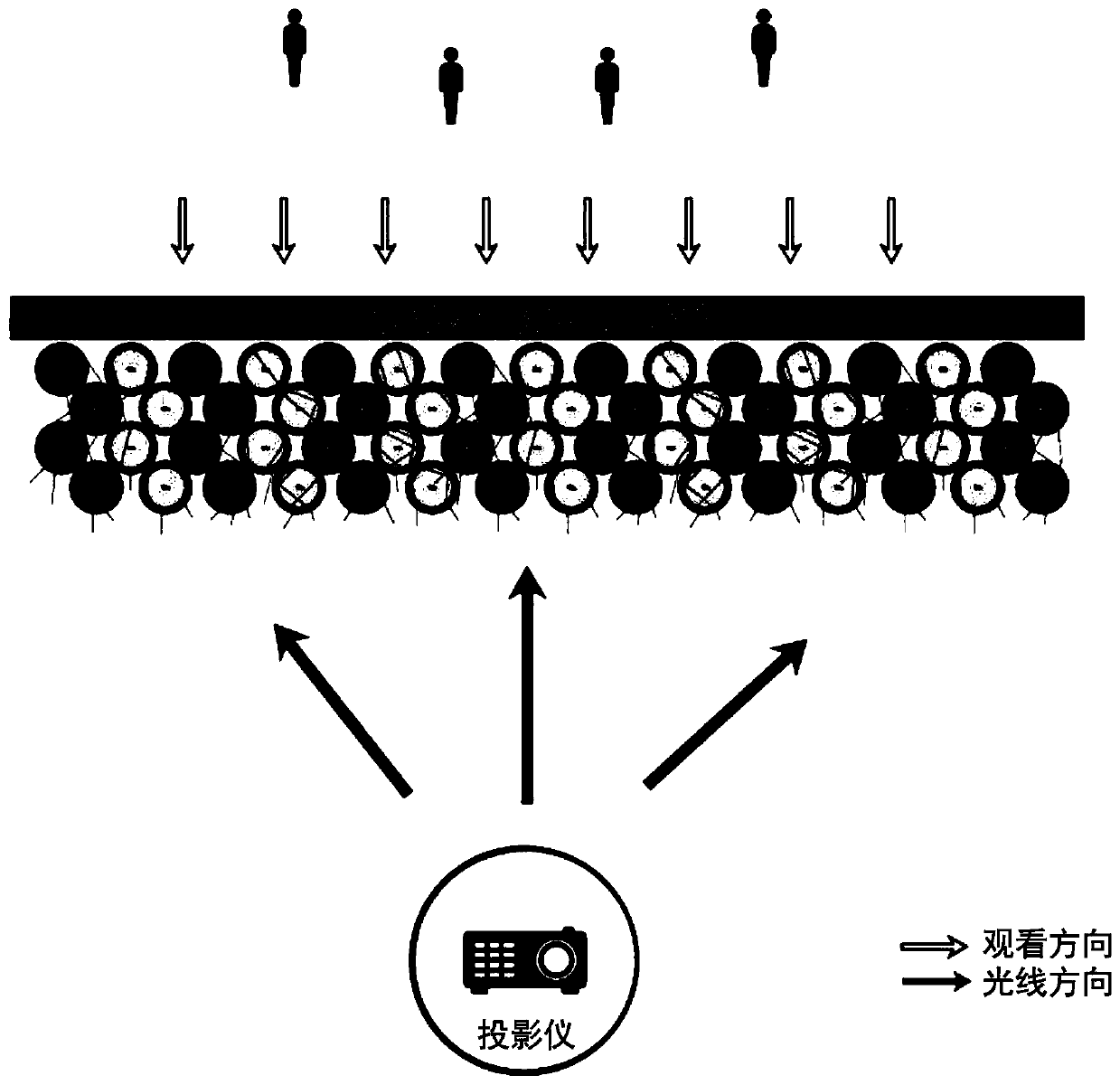

[0045] 3. Coating method for projector screen

[0046] (1) Coating tool used: planetary roller (used to make the thickness of 100% water-soluble paint or coating film thinner)

[0047] (2) Thickness of dry coating film: 30-40μm (coating twice, the second coating after 60 minutes after the first coating)

[0048] (3) Drying time (24 hours at 25°C)

[0049] (4) Beam projector used: 3000ANSI specificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com