Antiskid adhesive film and preparation method and application thereof

A film and anti-slip technology, applied in adhesives, heat-activated films/sheets, film/sheet release liners, etc., can solve the problems of thick thickness, poor anti-slip performance, poor elasticity of anti-slip structures, etc., and achieve excellent comfort , good skid resistance, good static and dynamic friction coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

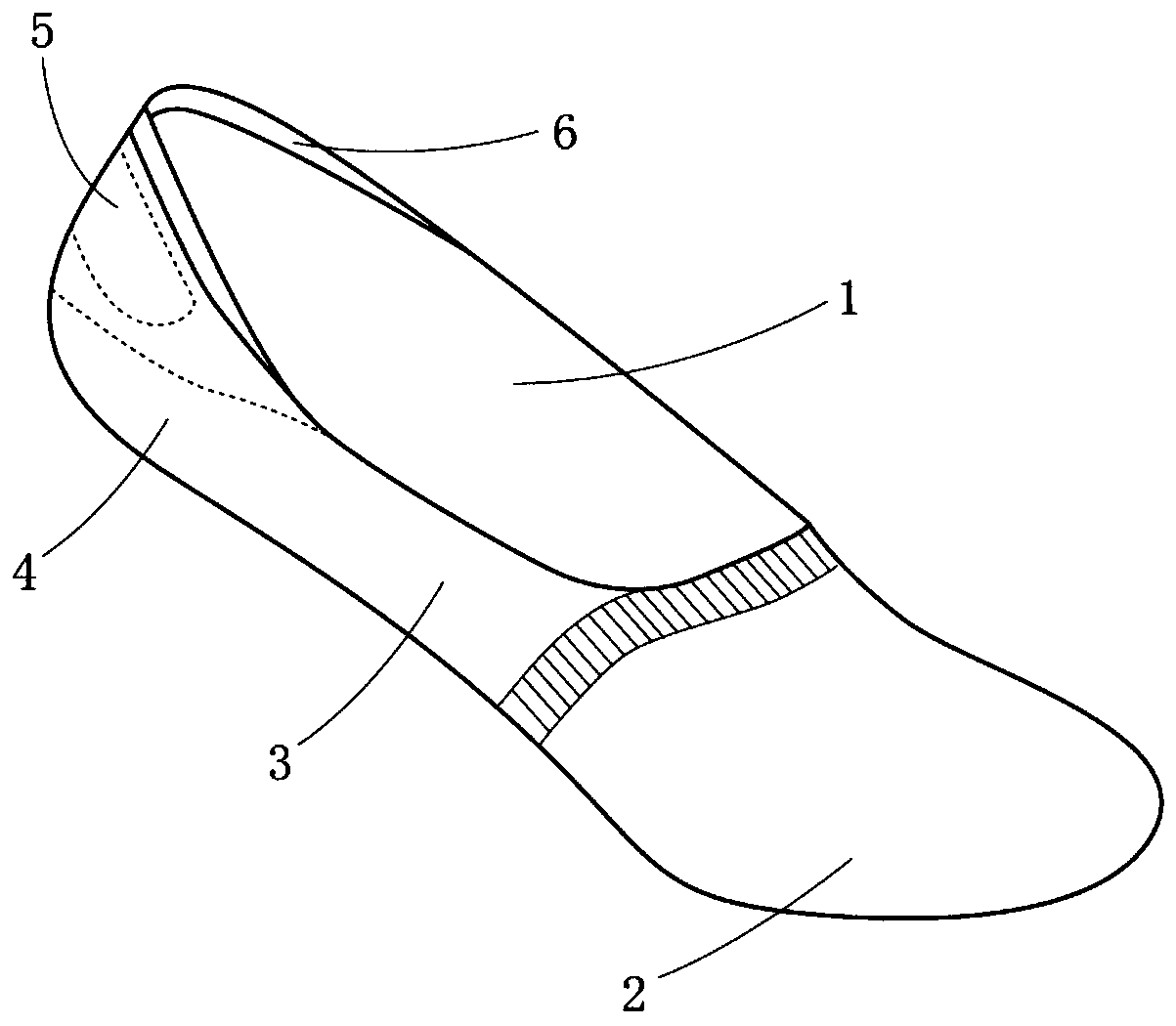

Image

Examples

Embodiment 1

[0028] An anti-slip adhesive film, comprising a hot-pressed adhesive film layer and a base layer laminated in sequence; the hot-pressed adhesive film layer is composed of the following raw material components: 35% SEBS, 25% high-viscosity paraffin oil, 34% low-viscosity paraffin oil, 3% titanium dioxide, 1% essence, 1% polypropylene, 0.5% antioxidant, 0.5% anti-sticking agent.

[0029] The preparation method of above-mentioned anti-slip adhesive film, comprises the following steps:

[0030] (1) adding the raw material of the anti-slip film into the mixer, then mixing at room temperature for 24 hours to obtain the mixture;

[0031] (2) Add the mixture obtained in step 1 into a twin-screw extruder with a temperature of 220°C, a pressure of 5 MPa, and a rotation speed of 200r / min, and extrude the product while reacting, and cast it against pressure to obtain a hot-pressed film layer;

[0032] (3) The hot-pressed adhesive film layer is laminated on the PE release film layer by d...

Embodiment 2

[0035] An anti-slip adhesive film, comprising a hot-pressed adhesive film layer and a base layer laminated in sequence; the hot-pressed adhesive film layer is composed of the following raw material components: 30% SEBS, 35% high-viscosity paraffin oil, 30% low-viscosity paraffin oil, Titanium dioxide 4%, essence 0.4%, polypropylene 0.3%, antioxidant 0.15%, anti-sticking agent 0.15%.

[0036] The preparation method of above-mentioned anti-slip adhesive film, comprises the following steps:

[0037] (1) Add the raw materials of the anti-skid film into the mixer, and carry out 24h mixing at normal temperature to obtain the mixture;

[0038] (2) Add the mixture obtained in step 1 into a twin-screw extruder with a temperature of 220°C, a pressure of 5 MPa, and a rotation speed of 200r / min, and extrude the product while reacting, and cast it against pressure to obtain a hot-pressed film layer;

[0039] (3) The hot-pressed adhesive film layer is laminated on the PE release film laye...

Embodiment 3

[0042] An anti-slip adhesive film, comprising a hot-pressed adhesive film layer and a base layer laminated in sequence; the hot-pressed adhesive film layer is composed of the following raw material components: SEBS 36%, paraffin oil high viscosity 24%, paraffin oil low viscosity 31%, Titanium dioxide 5%, essence 1.3%, polypropylene 1.2%, antioxidant 0.7%, anti-sticking agent 0.8%.

[0043] The preparation method of above-mentioned anti-slip adhesive film, comprises the following steps:

[0044] (1) Add the raw materials of the anti-skid film into the mixer, and carry out 24h mixing at normal temperature to obtain the mixture;

[0045] (2) Add the mixture obtained in step 1 into a twin-screw extruder with a temperature of 220°C, a pressure of 5 MPa, and a rotation speed of 200r / min, and extrude the product while reacting, and cast it against pressure to obtain a hot-pressed film layer;

[0046](3) The hot-pressed adhesive film layer is laminated on the PE release film layer b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com