High-temperature molten slag waste heat high-efficiency recycling device

A high-efficiency, molten slag technology, applied in the field of industrial waste slag treatment equipment, can solve problems such as erosion, loss of molten steel, and lower recovery rate, and achieve the effects of expanding the heating area, improving the use effect, and high use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

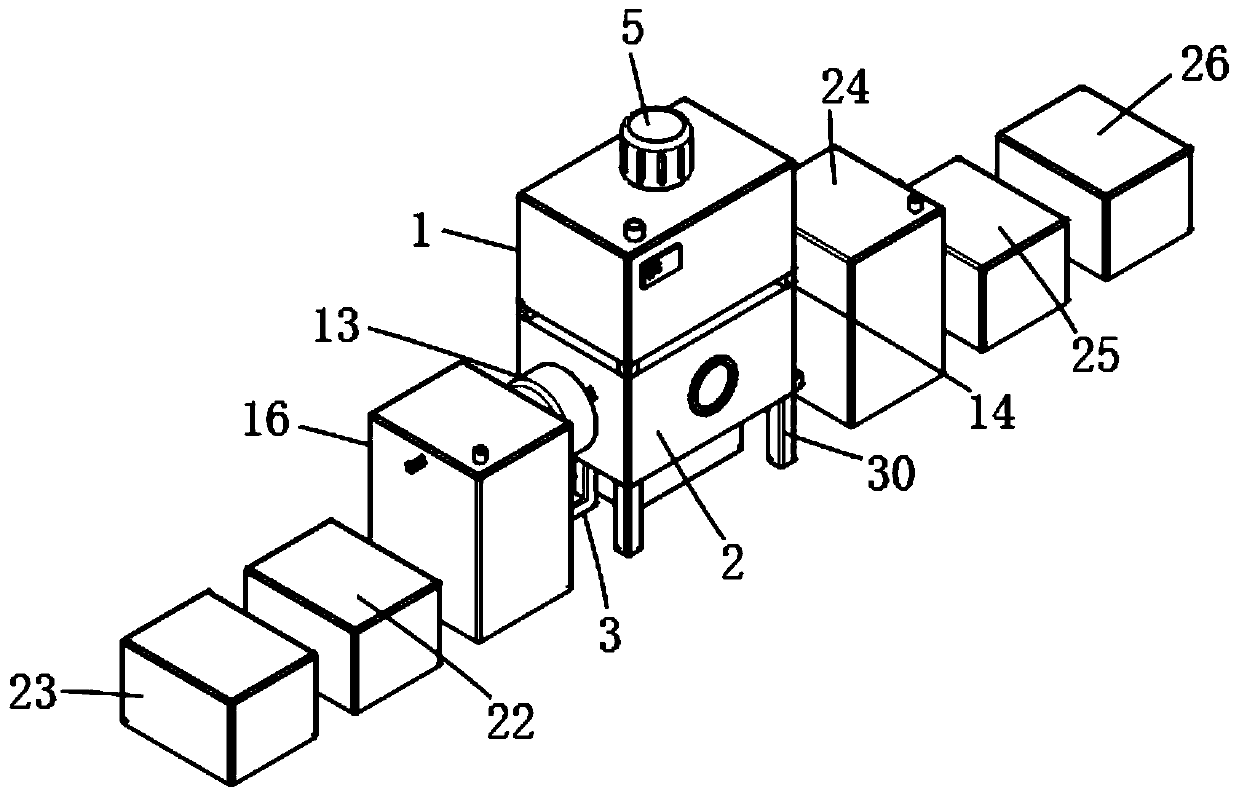

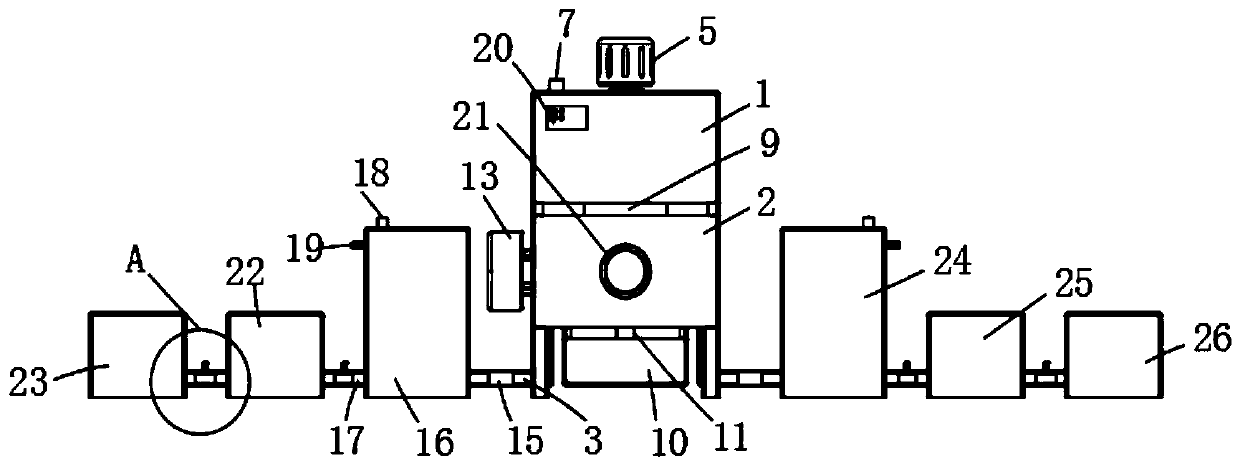

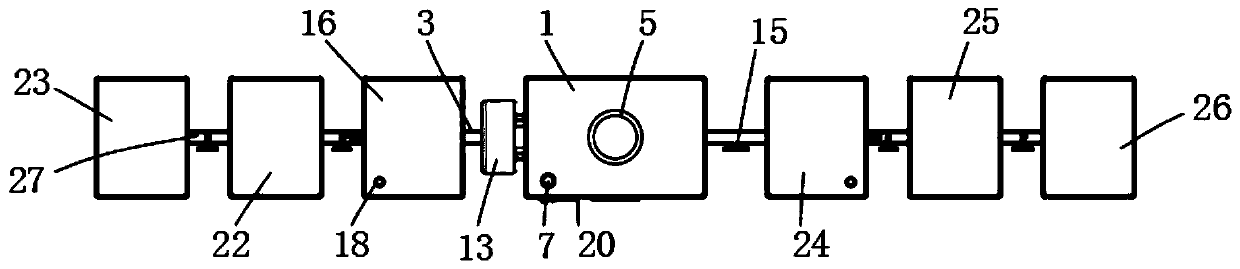

[0031] Please refer to Figure 1-7 Shown: a high-efficiency recovery and utilization device for high-temperature slag waste heat, including a material bin 1, a soaking bin 2 and a bracket 30, the bottom of the bin 1 is connected with a material guide port 9, and the input end of the soaking bin 2 is connected Port 9 is connected to facilitate the introduction of the slag material in the material bin 1 to the soaking bin 2 for further processing. The bottom of the soaking bin 2 is fixedly connected with several brackets 30 to support and fix the slag processing mechanism of the device. To improve the stability during operation, a material disturbance rod 4 is arranged inside the material bin 1, a driving motor 5 is installed on the upper surface of the material bin 1, and the output end of the driving motor 5 is connected to a driving shaft 6, and the material disturbing rod 4 is connected to the driving shaft 6 , use the driving motor 5 to drive the disturbing rod 4 through th...

Embodiment 2

[0036] Please refer to Figure 1-7 As shown: the first-level heat pipe 17 and the second-level heat pipe 27 are provided with two groups, the bottom surface of the second cooling pool 24 is connected to the third-level heat chamber 25 through the first-level heat pipe 17, and the third-level heat chamber 25 One surface of the bottom end is connected with a fourth-level thermal chamber 26 through a secondary heat-conducting pipe 27, which is equivalent to the first cooling pool 24 and its connection and use. The third-level thermal chamber 25 uses heat, and further passes the waste heat through the secondary The heat pipe 27 guides to the fourth-stage heat storehouse 26 to make full use of the waste heat, wherein the use of waste heat in the first cooling pool 16 and the second cooling pool 24 can be adjusted, and the waste heat in the first cooling pool 16 can be used for For production, the waste heat of the second cooling pool 24 can be used for daily life, and the use is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com