Low-density high-strength high-plasticity high-entropy alloy material and preparation method thereof

A high-entropy alloy, high-strength technology, applied in the field of metal materials, can solve the problems of large composition difference, difficult to handle, imperfect preparation process of low-density high-entropy alloy, etc., and achieve the effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

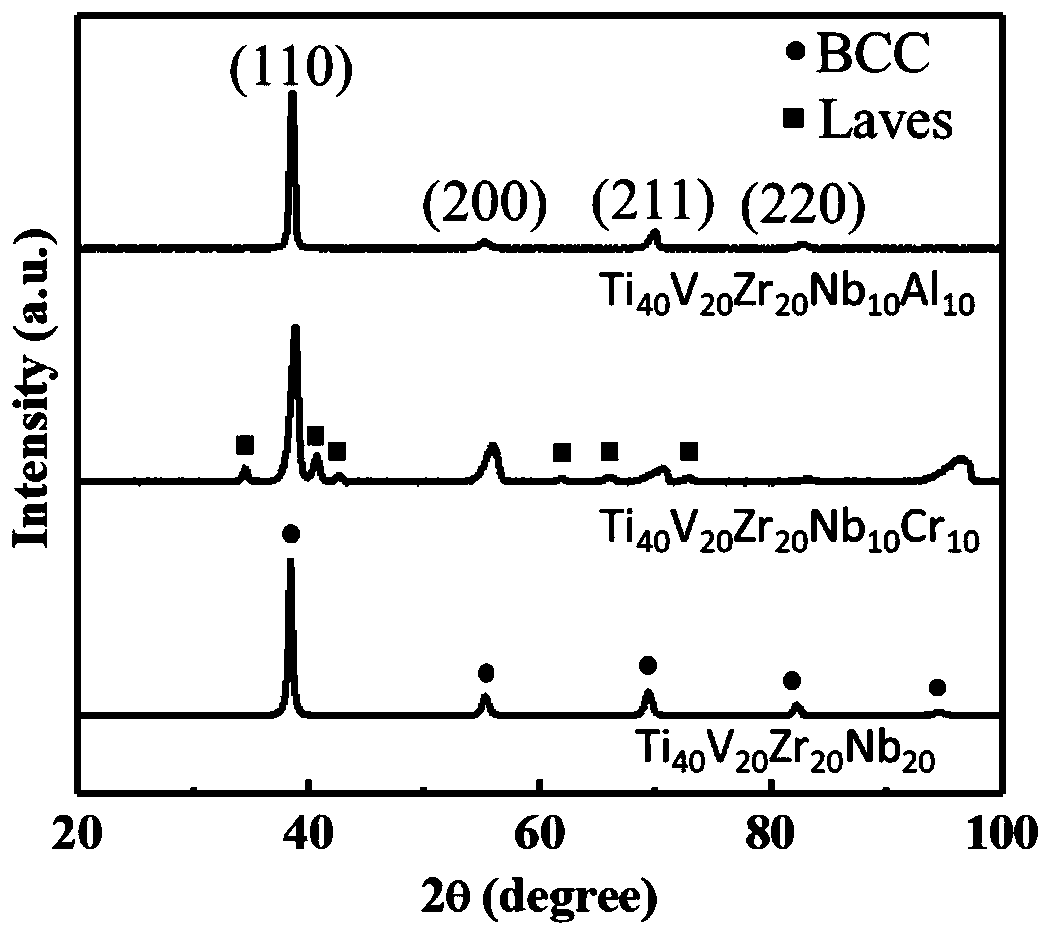

[0038] The embodiment of the present invention provides a Ti a V b Zr c Nb d x e A design and preparation method of a series of high-entropy alloy materials, including the following processes:

[0039] 1. Composition design

[0040] First, in order to obtain refractory high-entropy alloy materials with low density and high plasticity, we select low-density refractory alloy elements with intrinsic plasticity, including titanium (ρ Ti =4.54g / cm 3 ), vanadium (ρ V =6.11g / cm 3 ), zirconium (ρ Zr =6.50g / cm 3 ) and niobium (ρ Nb =8.57g / cm 3 )element. Secondly, in order to further reduce the alloy density, we choose chromium with lower density (ρ Cr =7.22g / cm 3 ) elements and ultra-light aluminum (ρ Al =2.70g / cm 3 ) element to replace the niobium element in the alloy. Finally, in order to ensure the formation of a single-phase solid solution structure after alloying and avoid the generation of intermetallic compounds that damage the properties of the alloy, we have c...

Embodiment 1

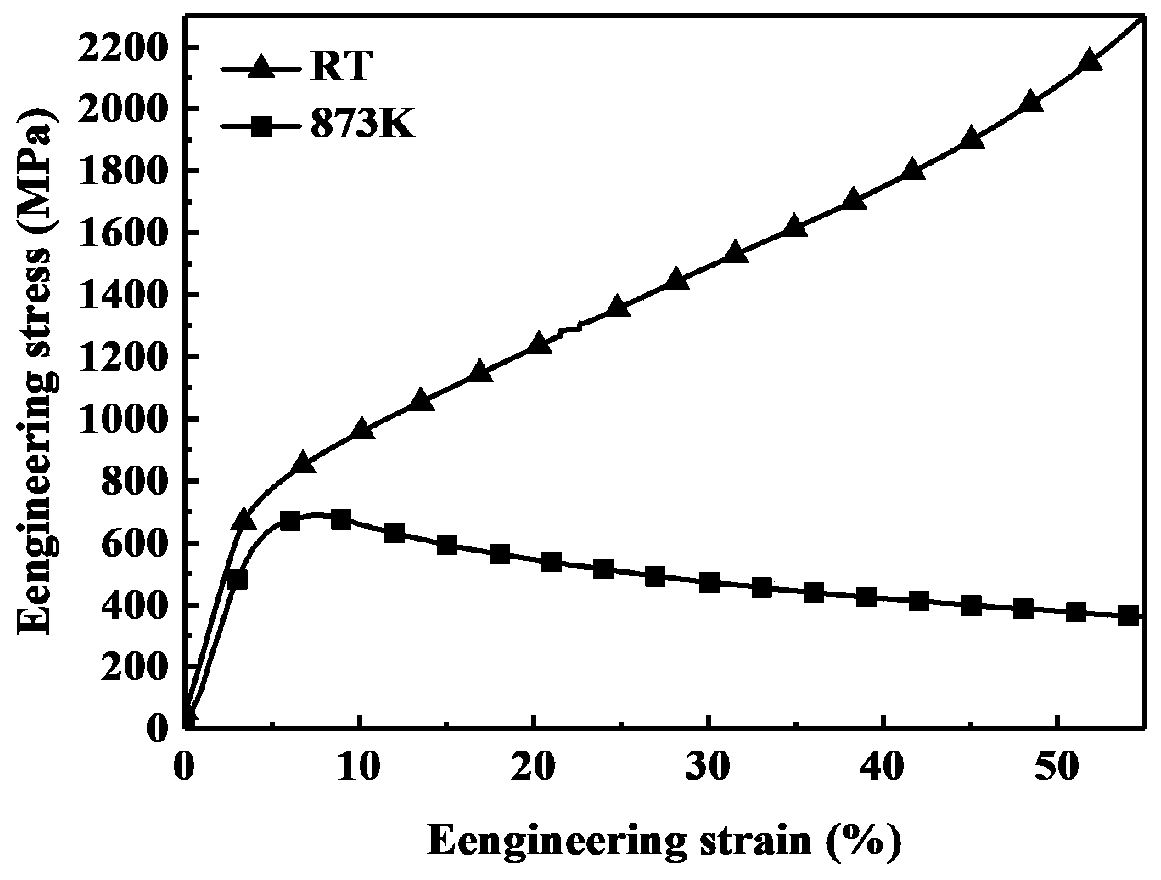

[0059] The embodiment of the present invention provides a Ti 40 V 20 Zr 20 Nb 20 High-entropy alloys are composed of four elements: Ti, V, Zr and Nb. The relative atomic percentage of Ti atoms is 40%, the relative atomic percentage of V atoms is 20%, and the relative atomic percentage of Zr atoms is 20%. The relative atomic percentage of Nb atoms is 20%.

[0060] The Ti 40 V 20 Zr 20 Nb 20 The purity of the metal element raw materials selected for the high-entropy alloy is higher than 99.95 at%.

[0061] The Ti 40 V 20 Zr 20 Nb 20 The preparation method of high entropy alloy is as follows:

[0062] Step 1: Select four metal elements Ti, V, Zr, and Nb, and clean the high-purity metal particles twice with an ultrasonic cleaner for 2 minutes each time; 40 V 20 Zr 20 Nb 20 The atomic percentage of high-entropy alloys is accurately weighed four metal elements such as Ti, V, Zr, and Nb; the copper crucible of the vacuum arc melting furnace is polished with sandpaper ...

Embodiment 2

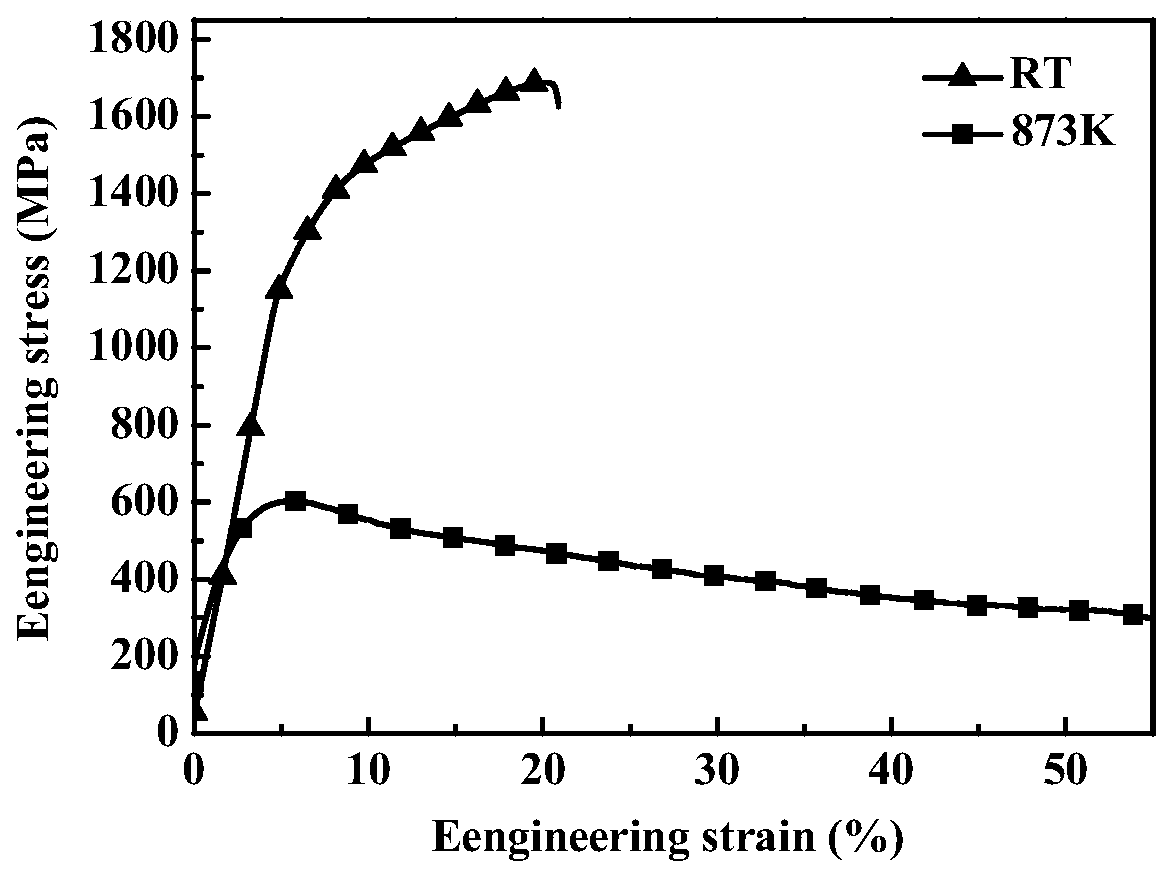

[0069] The embodiment of the present invention provides a Ti 40 V 20 Zr20 Nb 10 Cr 10 High-entropy alloys are composed of five metal elements: Ti, V, Zr, Nb and Cr. The relative atomic percentage of Ti atoms is 40%, the relative atomic percentage of V atoms is 20%, and the relative atomic percentage of Zr atoms is 20%, the relative atomic percentage of Nb atoms is 10%, and the relative atomic percentage of Cr atoms is 10%.

[0070] The Ti 40 V 20 Zr 20 Nb 10 Cr 10 The purity of the metal element raw materials selected for the high-entropy alloy is higher than 99.95 at%.

[0071] The Ti 40 V 20 Zr 20 Nb 10 Cr 10 The preparation method of high entropy alloy is as follows:

[0072] Step 1: Select five metal elements of Ti, V, Zr, Nb and Cr, and clean the high-purity metal particles twice with an ultrasonic cleaner for 2 minutes each time; 40 V 20 Zr 20 Nb 10 Cr 10 The atomic percentage of high-entropy alloys is accurately weighed five metal elements Ti, V, Zr, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap