A production process of geotextile

A technology of geotextiles and production equipment, which is applied in the production field of new geotextiles, can solve the problems of poor anti-ultraviolet performance of geotextiles, easy deviation, local aging, etc., achieve good anti-ultraviolet aging, ensure normal construction, and good The effect of waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

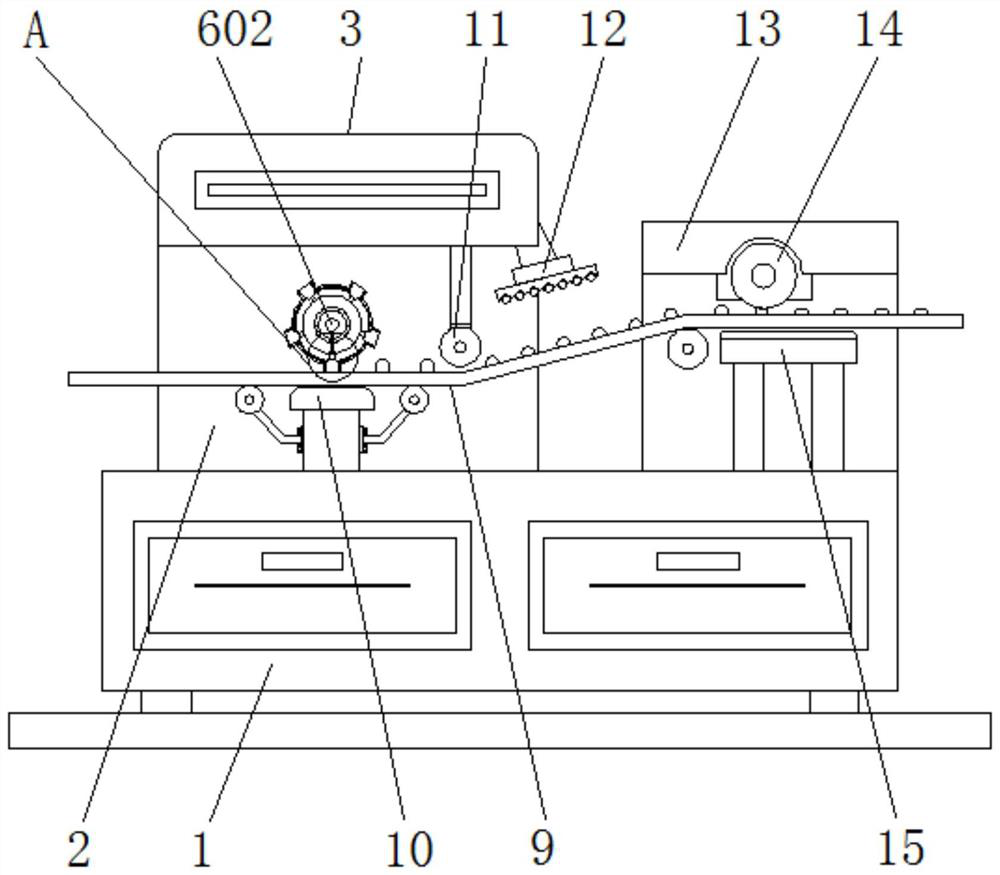

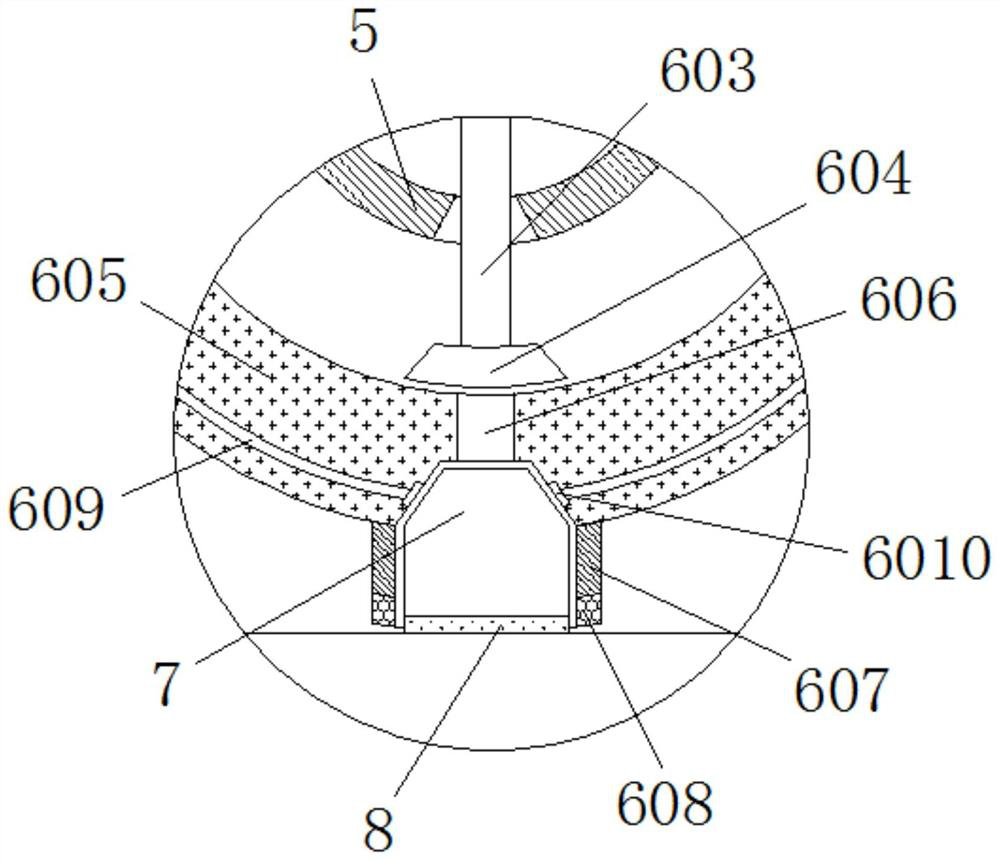

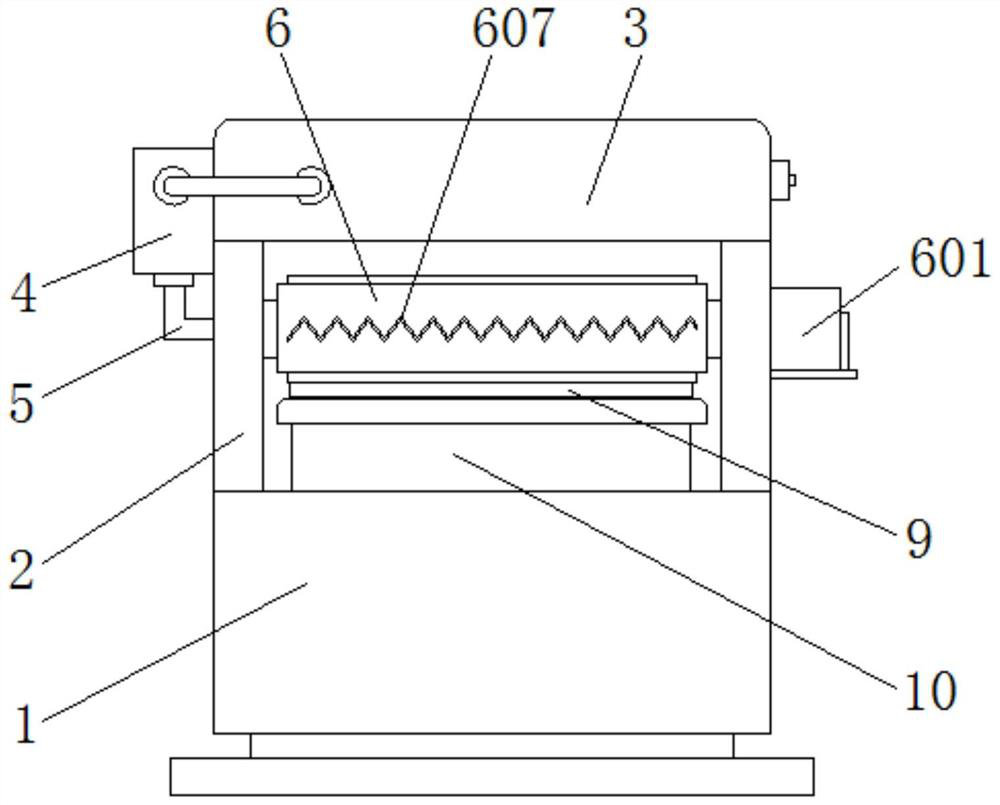

[0052] see Figure 1-8 , a production process of geotextiles, its production equipment includes a processing box 1, the upper side of the processing box 1 is fixedly installed with a control box 2, the top of the control box 2 is fixedly installed with a hot-melt box 3, and the rear side of the hot-melt box 3 An extraction mechanism 4 is fixedly installed, the output end of the extraction mechanism 4 is connected to an output pipe 5, and a thermal printing mechanism 6 is arranged outside the output pipe 5. The thermal printing mechanism 6 includes a driving motor 601, and the output end of the driving motor 601 is connected to a rotating shaft 602, the bottom of the rotating shaft rod 602 is fixedly installed with a mounting rod 603, the bottom of the mounting rod 603 is provided with a cutting blade 604, the outside of the cutting blade 604 is provided with a thermal printing shaft 605, and the outer end of the thermal printing shaft 605 is connected with a discharge port 607 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com