Section steel support composite splayed system for deep foundation pit

A technology of compound eight-character and deep foundation pits, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of small construction space under the support, difficult to deploy construction equipment, and narrow construction work surface, etc., to achieve multiple operating radius and save labor , the effect of multi-steel usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

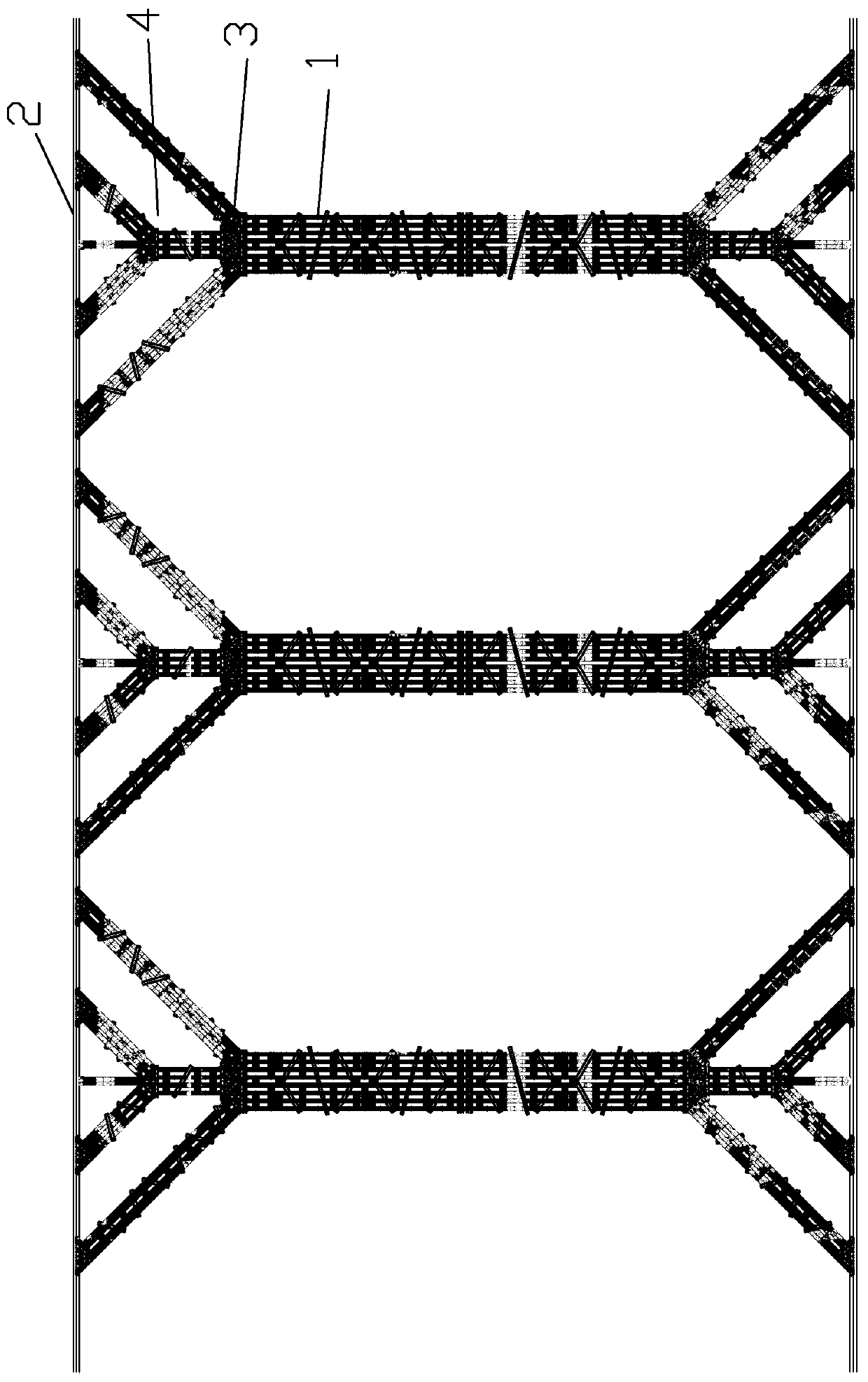

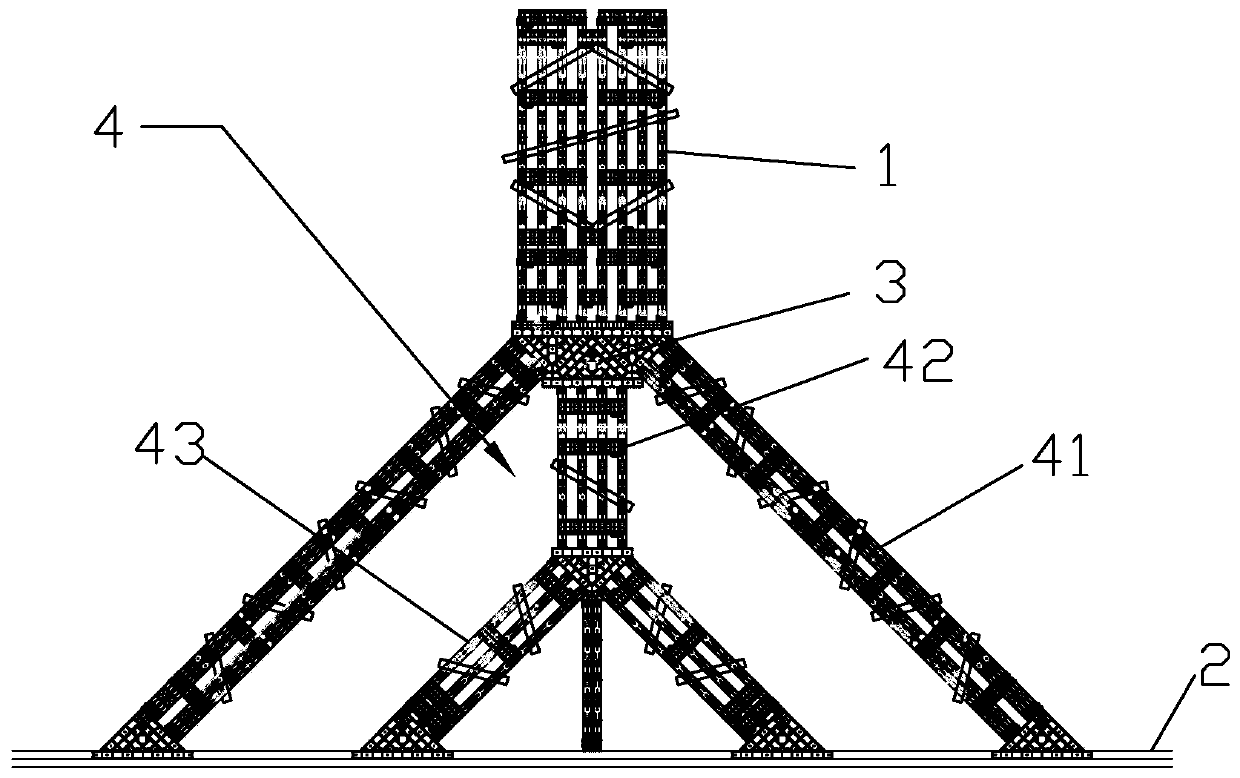

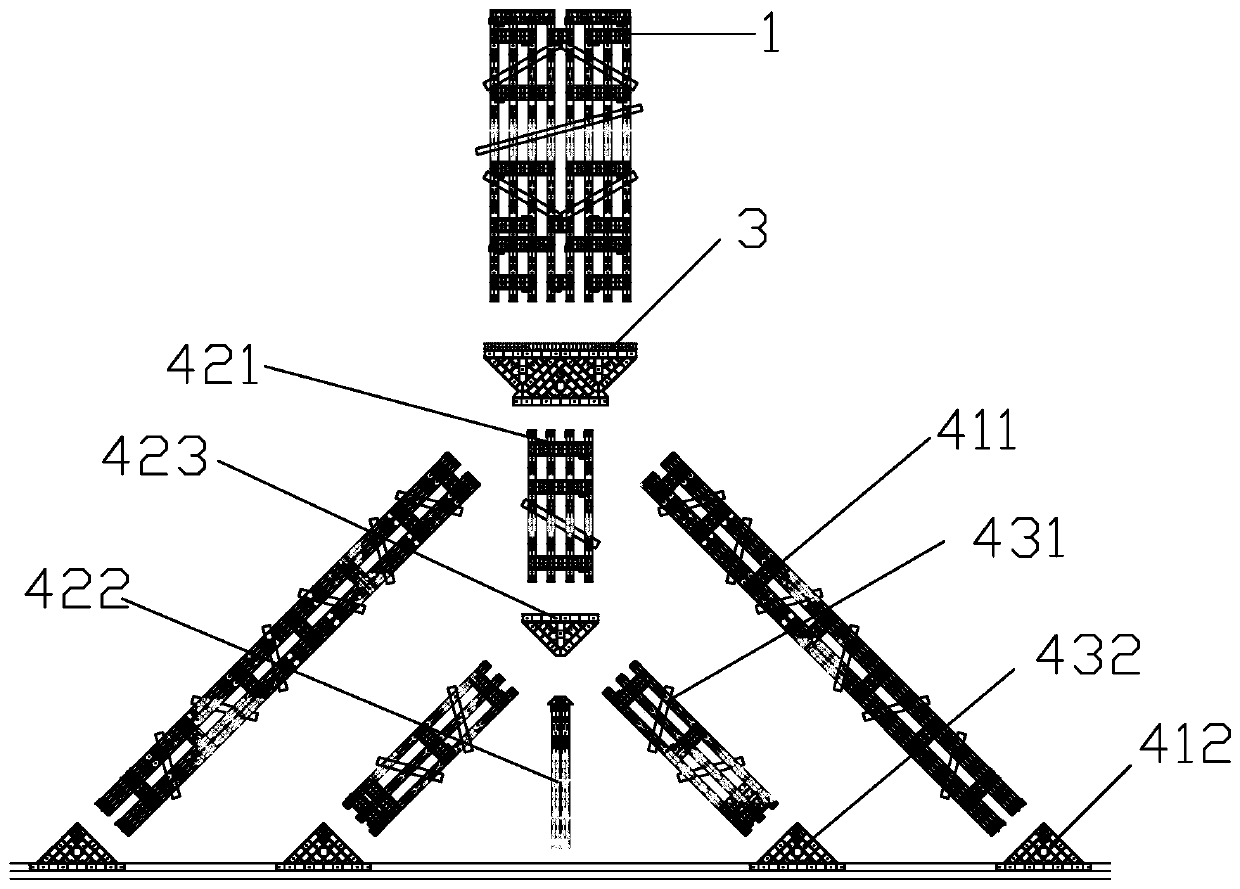

[0048] like Figure 1 to Figure 7 As shown in the figure, the deep foundation pit is supported with a composite eight-character system by a profiled steel, including a central profiled steel inner support girder 1 and an outer purlin beam 2, and both ends of the profiled steel inner support main beam 1 are provided with multi-triangular joint members 3. The outer side of the multi-triangular joint member 3 is provided with a composite figure-eight inclined support structure 4 , and the outer side of the composite figure-eight inclined support structure 4 is provided with the surrounding purlin beam 2 .

[0049] The section steel inner supporting main beam 1 in the middle is mainly formed by connecting I-shaped steel or H-shaped steel. Through the deep foundation pit support composite eight-shaped system designed by this application, the number of section steels that can be accommodated by one section steel inner supporting main beam 1, There can be up to 16 sections of steel, ...

Embodiment 2

[0056] see Image 6 , or the inner sleeve slanted beam 431 is pressed against both sides of the middle auxiliary support sub-beam 422 through the inner sleeve auxiliary triangular piece 432 to form an inner sleeve triangular support, and the outer end of the inner sleeve slanted beam 431 passes through the inner sleeve The auxiliary triangular piece 432 is fixedly connected to the inner side surface of the purlin beam 2 .

Embodiment 3

[0058] see Figure 7 , the inner sleeve slanted beam 431 is pressed against the two sides of the middle auxiliary supporting main beam 421 through the inner sleeve auxiliary triangular piece 432 to form an inner sleeve triangular support, and the outer end of the inner sleeve slanted beam 431 is supported by the inner sleeve. The triangular piece 432 is fixedly connected to the inner surface of the purlin beam 2 .

[0059] In order to adapt to various scenarios of foundation pit operations, according to the width of the foundation pit, the inner sleeve slanted beam assemblies 43 of the above three embodiments can be implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com