Small-section long-distance soft rock tunnel construction method

A construction method and small-section technology, applied in the construction field of infrastructure engineering technology, can solve problems such as ambiguous design specifications and standards for waterproofing and drainage, inconsistent principles and selection methods for waterproofing and drainage, and difficulties in technical measures for waterproofing and drainage, etc. Poor self-stability of soft rock, good working environment, and the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

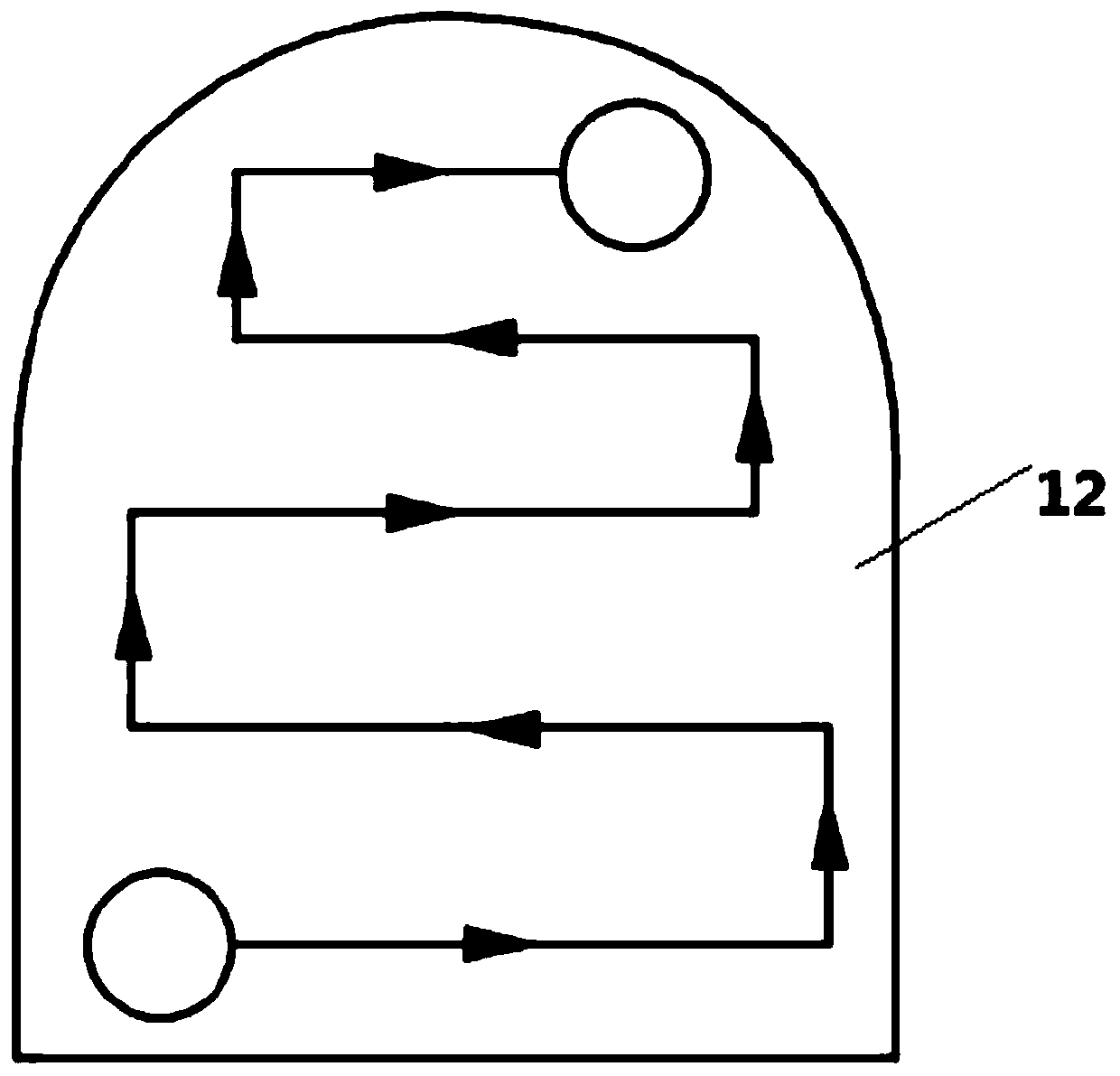

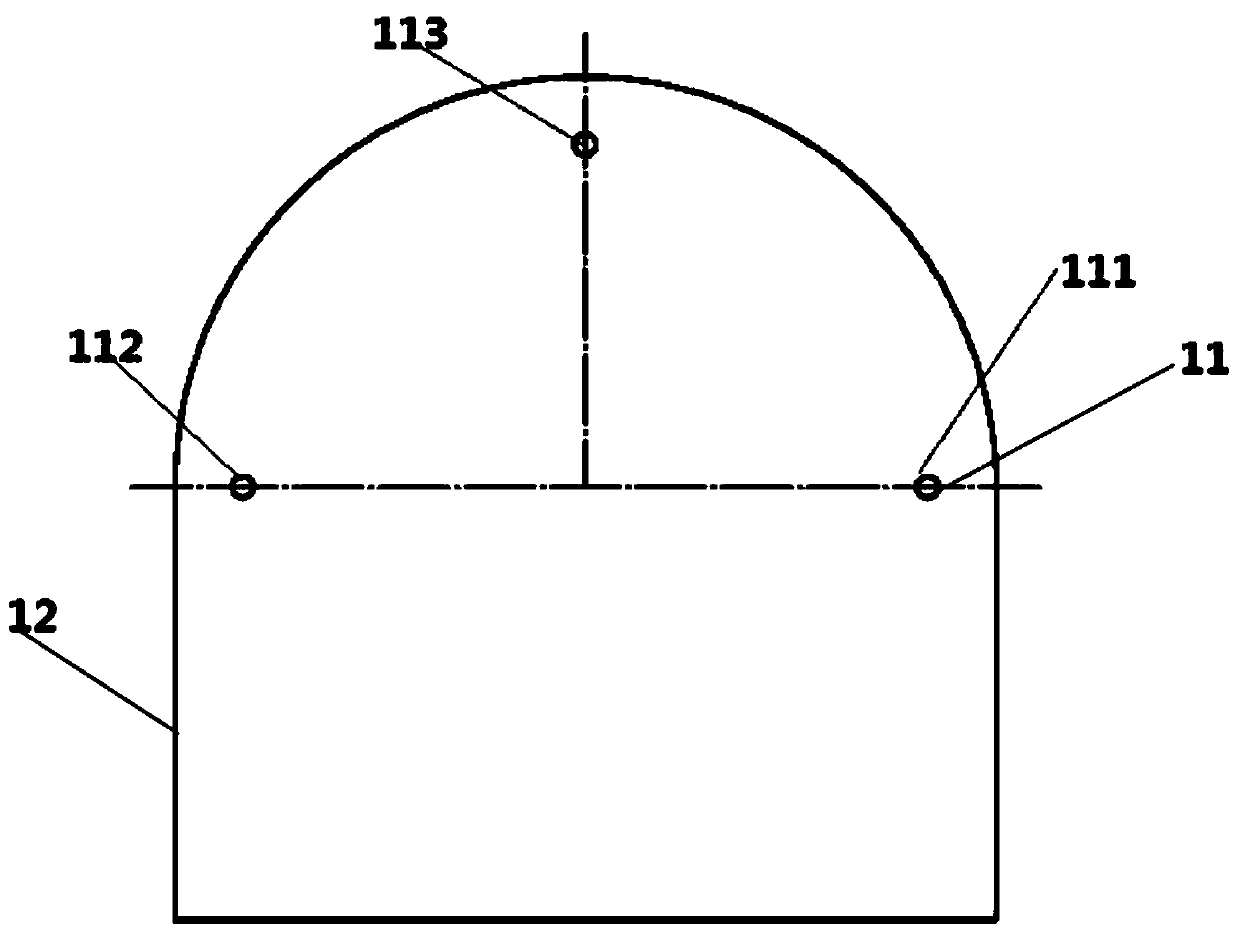

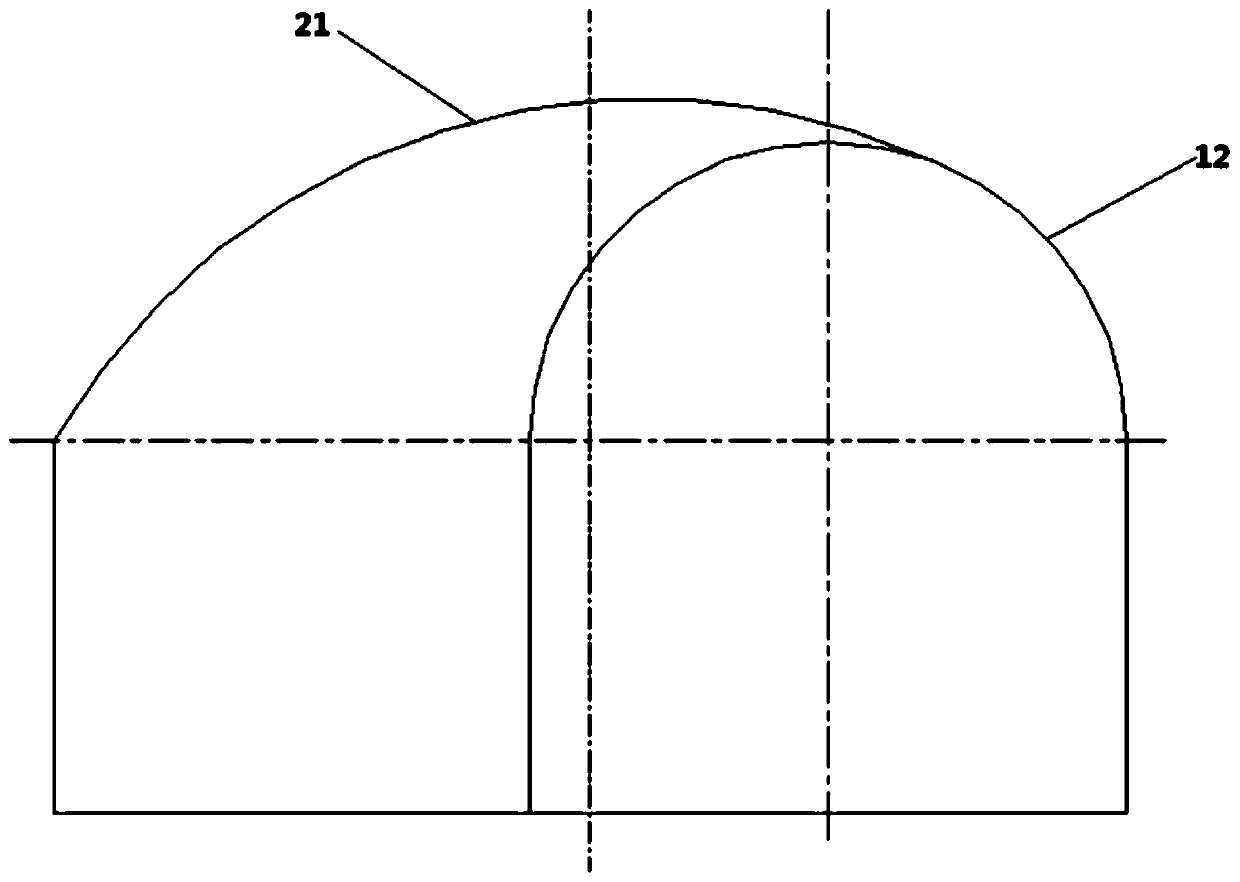

[0050] see Figure 1-7 A construction method for a small-section long-distance soft rock tunnel shown, comprising the following steps:

[0051] 1. Excavation in the tunnel and dust removal in the tunnel

[0052] (1) Roadheader excavation

[0053] First, clean the surface of the cantilever roadheader, the second conveyor, the laser pointing device, the fan, and the site; do a good job of field leveling to ensure accurate positioning of the laser pointing device and a good construction environment for the cantilever roadheader;

[0054] Then install the laser pointer by professional surveyors,

[0055] After the laser pointing device is installed and fixed firmly, use measuring instruments to measure the position and direction of the laser center line of the laser pointing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com