Real-time sampling and judging method for steel manufacturing system

A manufacturing system and judgment method technology, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as difficult and precise operation, achieve the effect of reducing the number of sampling and testing times, and improving the delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

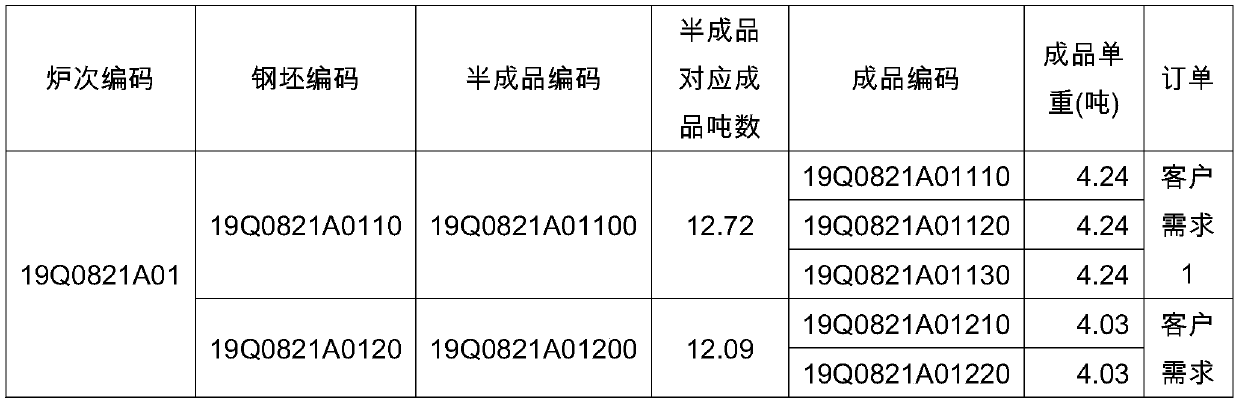

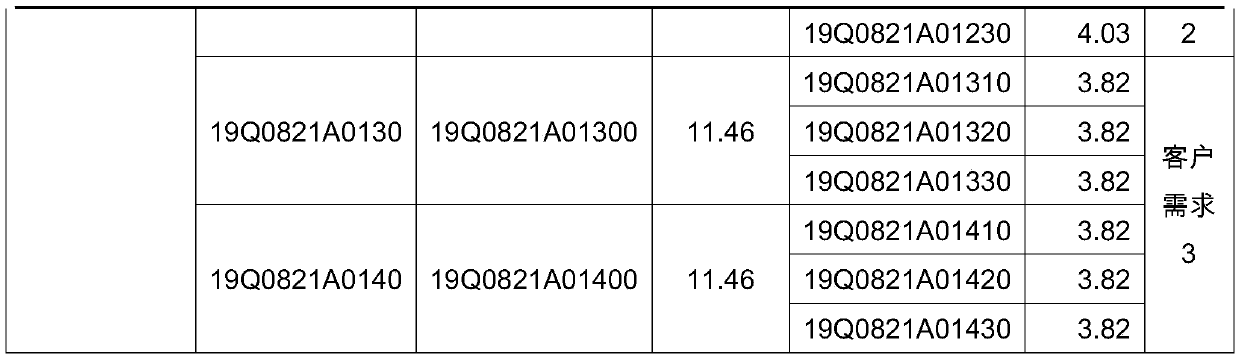

[0024] A specific implementation of a real-time sampling and determination method for a steel manufacturing system:

[0025] 1. Definition of inspection items

[0026] The manufacturing system first defines the inspection items, and then independently configures the corresponding parameters under the inspection items. The parameters include but are not limited to: sampling method (heat sampling, piece sampling, batch sampling, etc.), batch tonnage, grade, sampling location ( head, tail, etc.), thickness lower limit, thickness upper limit (when it is empty, the thickness is equal to the thickness lower limit), process delivery status, sample quantity, sample width, sample length, test condition parameters (such as test temperature), Test parameter 1 judgment standard (including parameter lower limit, parameter upper limit, and parameter range three parts, when the parameter upper limit is empty, it means it is equal to the lower limit), test parameter 2 judgment standard, test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com