Cable partial discharge high-precision positioning and noise removing method and device

A partial discharge, high-precision technology, applied in the direction of measuring devices, testing dielectric strength, measuring electricity, etc., can solve the lack of cost-effective monitoring solutions for distribution cables, cannot record the cable aging process in real time, and cannot reflect cable degradation and faults and other issues, to achieve the effect of time synchronization and positioning, improve efficiency, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

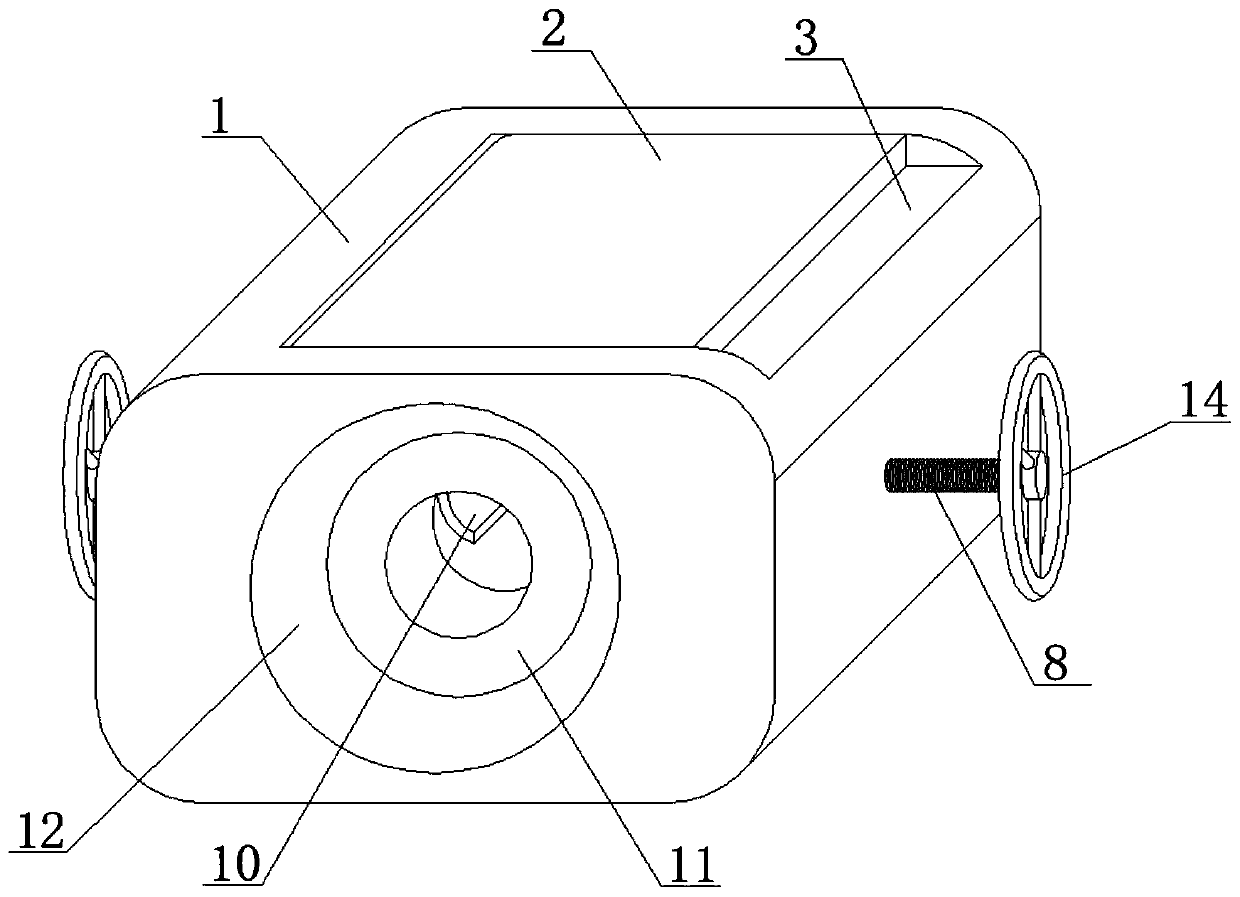

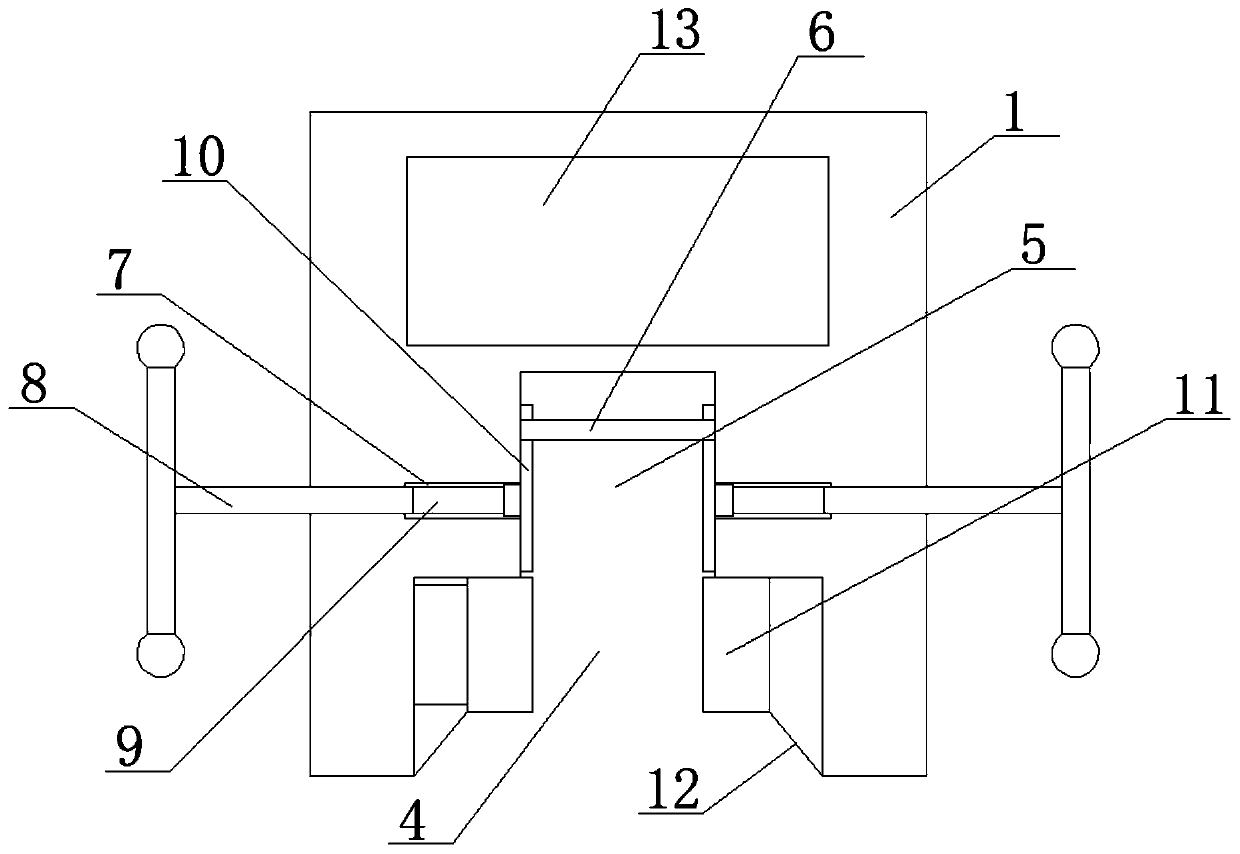

[0025] As a preferred embodiment of the present invention, a processor and a storage battery 13 are installed in the housing 1, the processor is electrically connected to the current transformer 11, and the storage battery 13 is electrically connected to the processor through a power supply circuit, The processor is electrically connected to the arc-shaped metal splint 10 through a communication circuit.

[0026] As a preferred embodiment of the present invention, a round handle 14 is fixedly installed at one end of the screw rod 8 .

[0027] As a preferred embodiment of the present invention, there are two screw rods 8 , insulating rods 9 and arc-shaped metal splints 10 .

[0028] A method for high-precision positioning and noise removal of cable partial discharge, comprising the following steps:

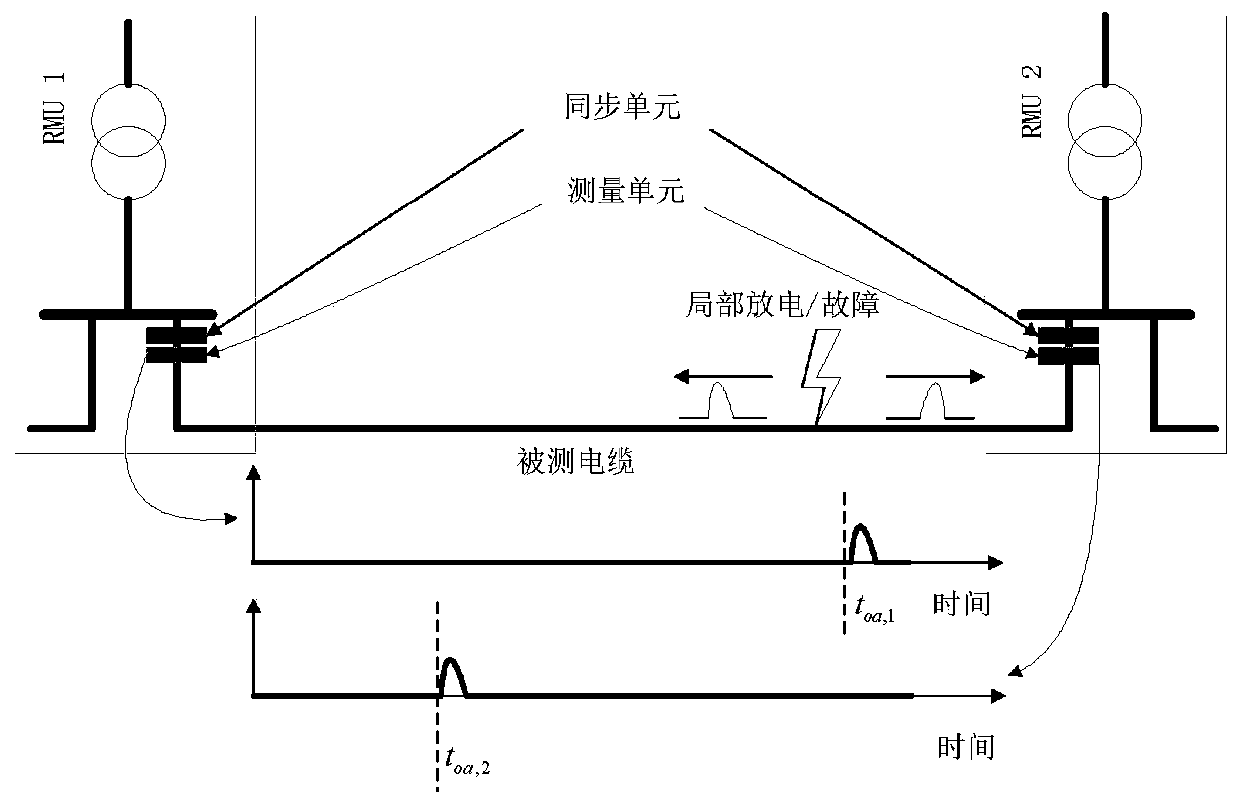

[0029] Step 1: The transformers at both ends are synchronized; the long-distance monitoring of the partial discharge of the medium-voltage cable is realized by installing a measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com