Automatic ICT test device

A test device and automatic technology, applied in the direction of measuring device, electronic circuit test, measuring electricity, etc., can solve the problems of low automation, achieve high automation, reduce time cost, and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

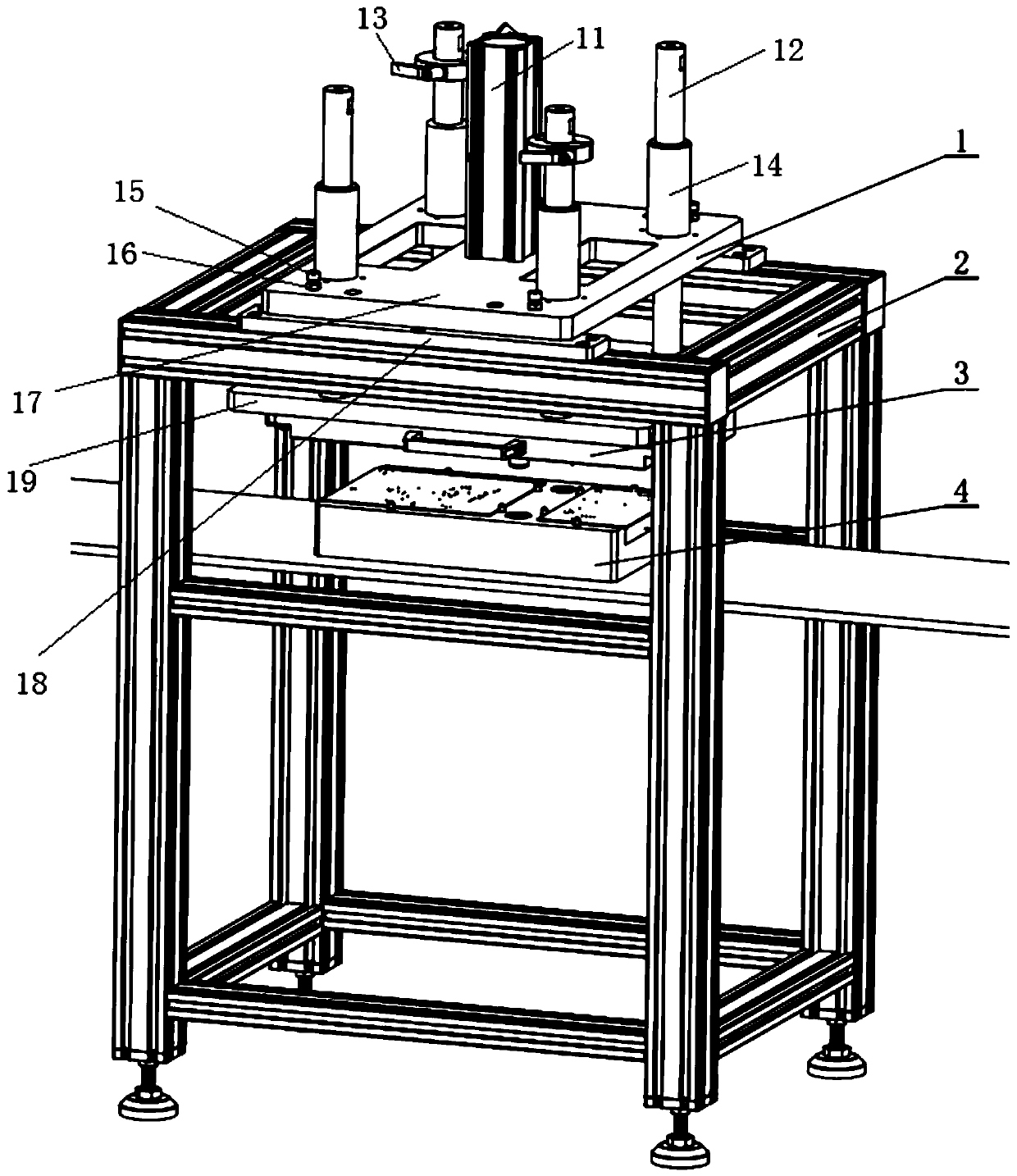

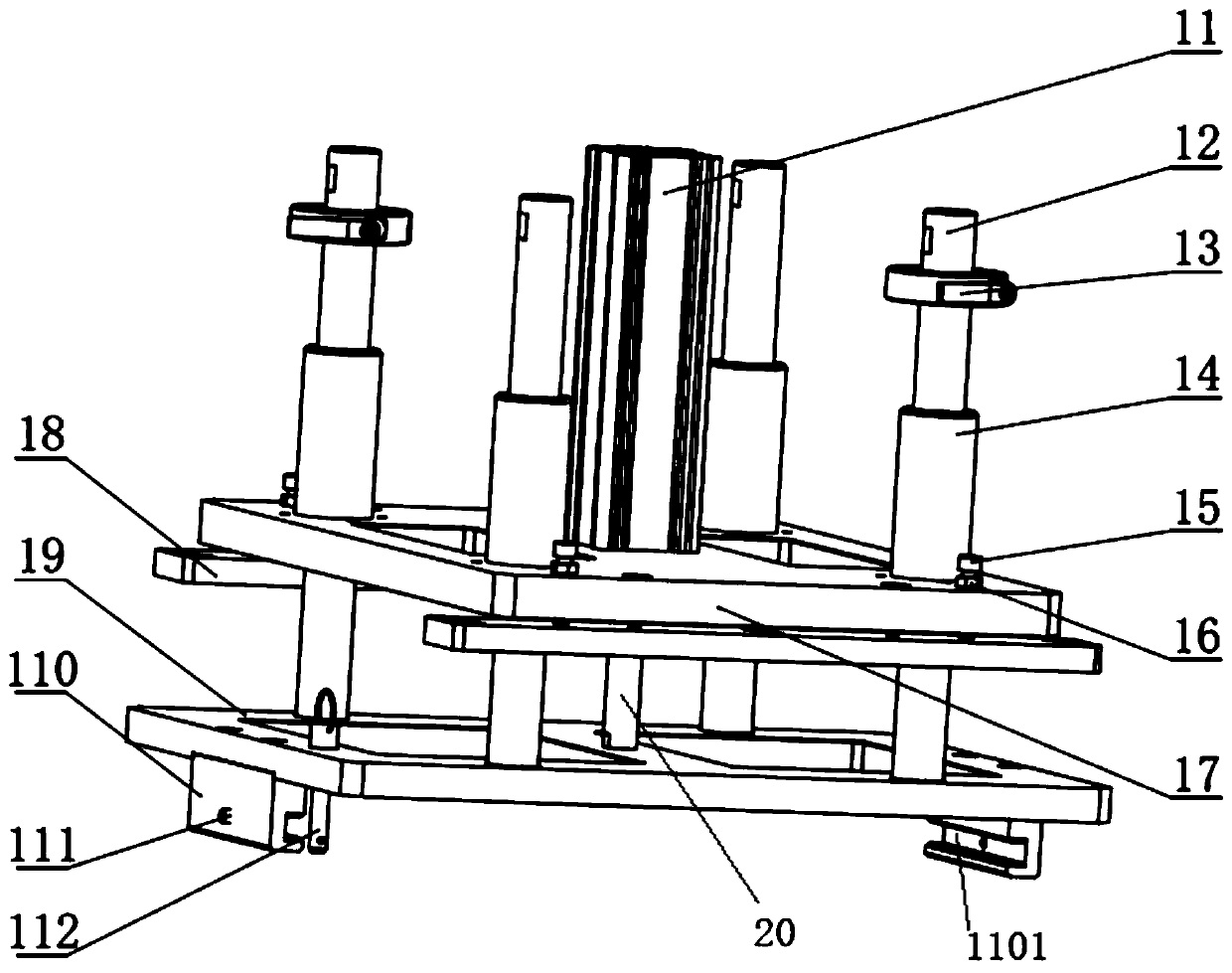

[0036] An embodiment of the present invention provides an automatic ICT testing device.

[0037] Principle description: The lifting mechanism 1 is integrally installed on the mechanism frame 2, and its function is to drive the probe fixture 3 to realize lifting and lowering. When it is raised, operations such as the replacement of the probe fixture and the placement, transmission, and adjustment of the circuit board fixture 4 can be carried out; The corresponding test points on the circuit board 43 are in contact, so as to realize the detection and programming of the circuit board 43 to be tested.

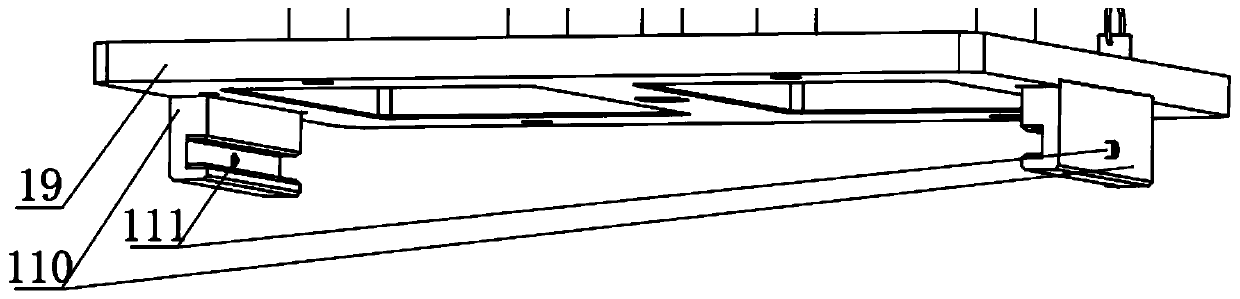

[0038] Such as figure 1 and 2As shown, the lifting mechanism 1 is fixed to the mechanism frame 2 through the leveling plate 18, and the leveling screw 15 is installed between the leveling plate 18 and the jig mounting plate 17, and its function is to adjust the level of the lifting mechanism 1 to make it compatible with the circuit board jig. The circuit board 43 to be tested on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com