High-reliability electronic product reliability verification method

A technology of electronic products and verification methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as no historical data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

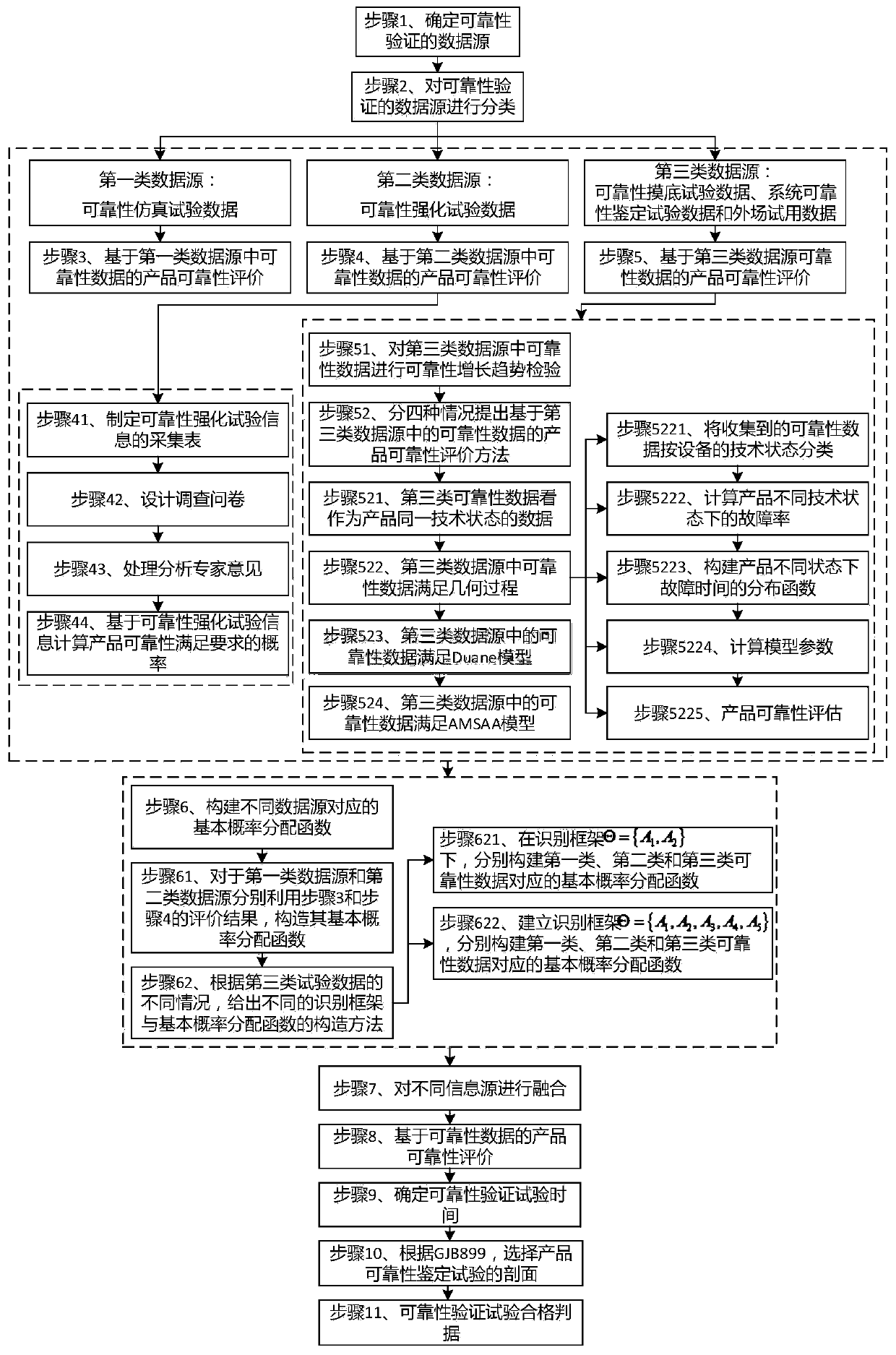

Method used

Image

Examples

Embodiment 1

[0142] A certain product has completed 1000 reliability simulation tests during the development process, and obtained the working time t before the first failure of 1000 products 1 ,t 2 ,…,t 1000 . During the reliability enhancement test of the product, there were 2 responsible faults and 1 non-responsible fault. One fault occurred in the low temperature step stress test, and the fault conditions are shown in Table 8; 2 faults occurred during the comprehensive environmental test, and the fault conditions were shown in Table 9; the high temperature step stress test, vibration stress test and rapid temperature change test did not error occured.

[0143] The product has completed 1,000 hours of reliability testing during the development process, and no failure has occurred during the period; 1,500 hours of reliability identification test has been carried out with the system, and no failure has occurred during the period;

[0144] There was no failure during the field trial, a...

Embodiment 2

[0227] A certain product has completed 1000 reliability simulation tests during the development process, and obtained the working time t before the first failure of 1000 products 1 ,t 2 ,…,t 1000 . The product did not fail during the reliability enhancement test. The product has completed a 300-hour reliability test during the development process, during which 3 faults occurred. The faults occurred for 11 hours, 48 hours and 176 hours respectively; 1500 hours of reliability identification tests were carried out with the system. One failure occurred 313 hours after the test; the field trial time was two failures during the field trial, and the failure time was 296 hours and 5274 hours after the field trial began; these six failures were taken Instant correction. The reliability requirement value of the product is 5000 hours. According to the data of the development and trial process, it is verified whether the reliability of the product meets the requirements.

[0228] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com