Submerged-arc welding system for inner circle and outer circle of large cylinder

A submerged arc welding, inner and outer circle technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of low welding efficiency, difficult to guarantee welding quality, and long manual assistance time, so as to reduce work intensity and improve welding efficiency and welding quality, and realize the effect of remote monitoring operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

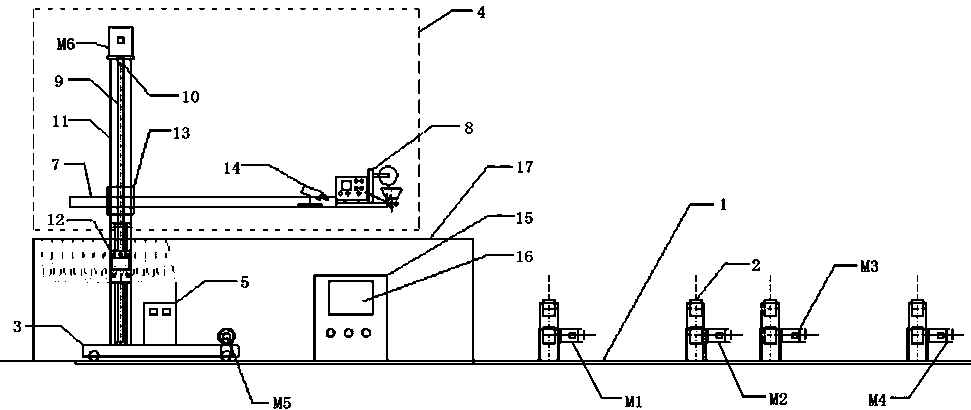

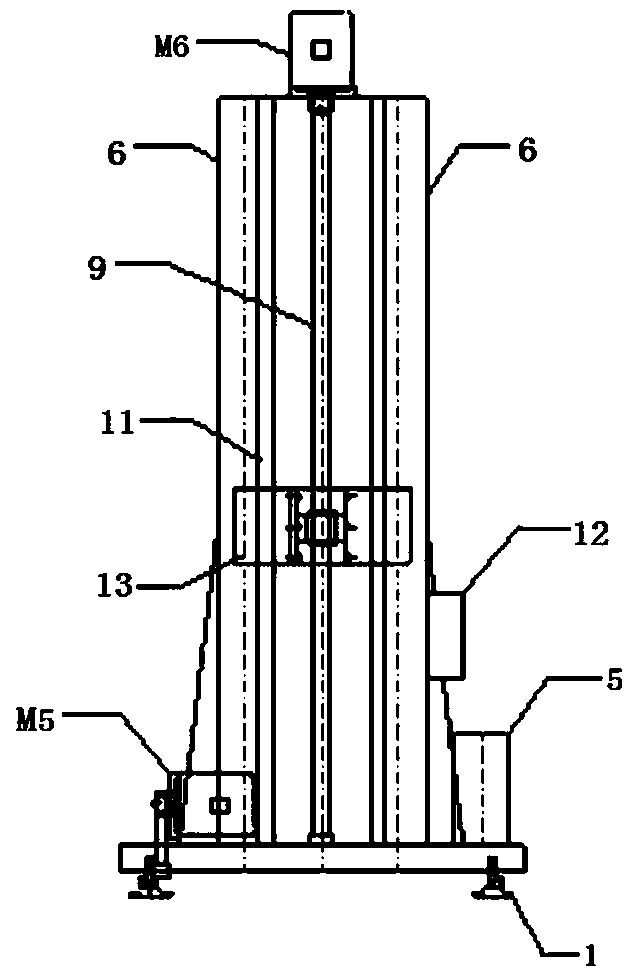

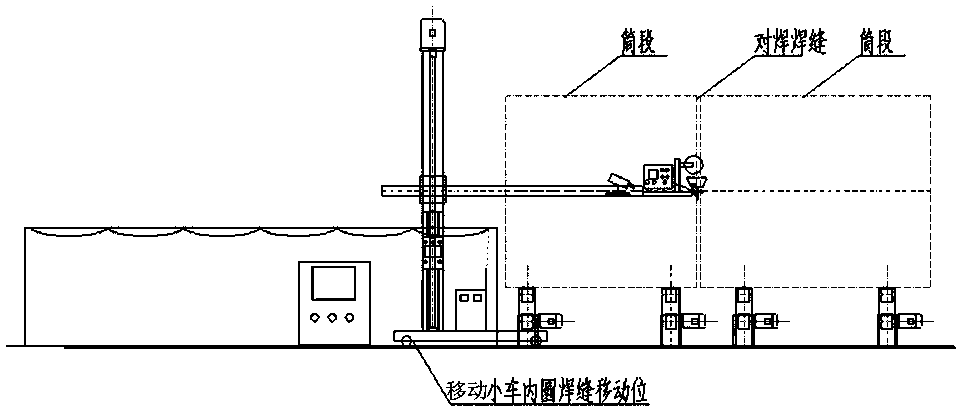

[0039] Such as Figure 1 to Figure 8 As shown, the large cylindrical inner and outer circular submerged arc welding system of the present invention includes a guide rail 1 and round rollers 2 arranged in parallel at both ends of the guide rail 1, and the round rollers 2 are driven by a driving motor;

[0040] The guide rail 1 is also provided with a mobile trolley 3, the mobile trolley 3 is provided with an arc welding device 4 and an on-board control cabinet 5, and the mobile trolley 3 is controlled and driven by a walking motor installed on the trolley floor;

[0041] The arc welding device 4 is provided with a pair of lifting columns 6, a submerged arc welding machine mounting arm 7, and a submerged arc welding machine 8. The lifting columns 6 are specifically vertically arranged on the moving trolley 3. The two lifting columns Also be provided with lifting screw mandrel 9 between each lifting column 6, the top installation of described lifting column 6 is provided with lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com