Point light source reading laser encryption holographic anti-counterfeiting gasket and preparation method thereof

A holographic anti-counterfeiting, point light source technology, applied in the field of point light source reading laser encryption holographic anti-counterfeiting gasket and its preparation, can solve the problems of loss of anti-counterfeiting ability, unfavorable promotion, inability to distinguish true from false, etc., and achieves a convenient authenticity query. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

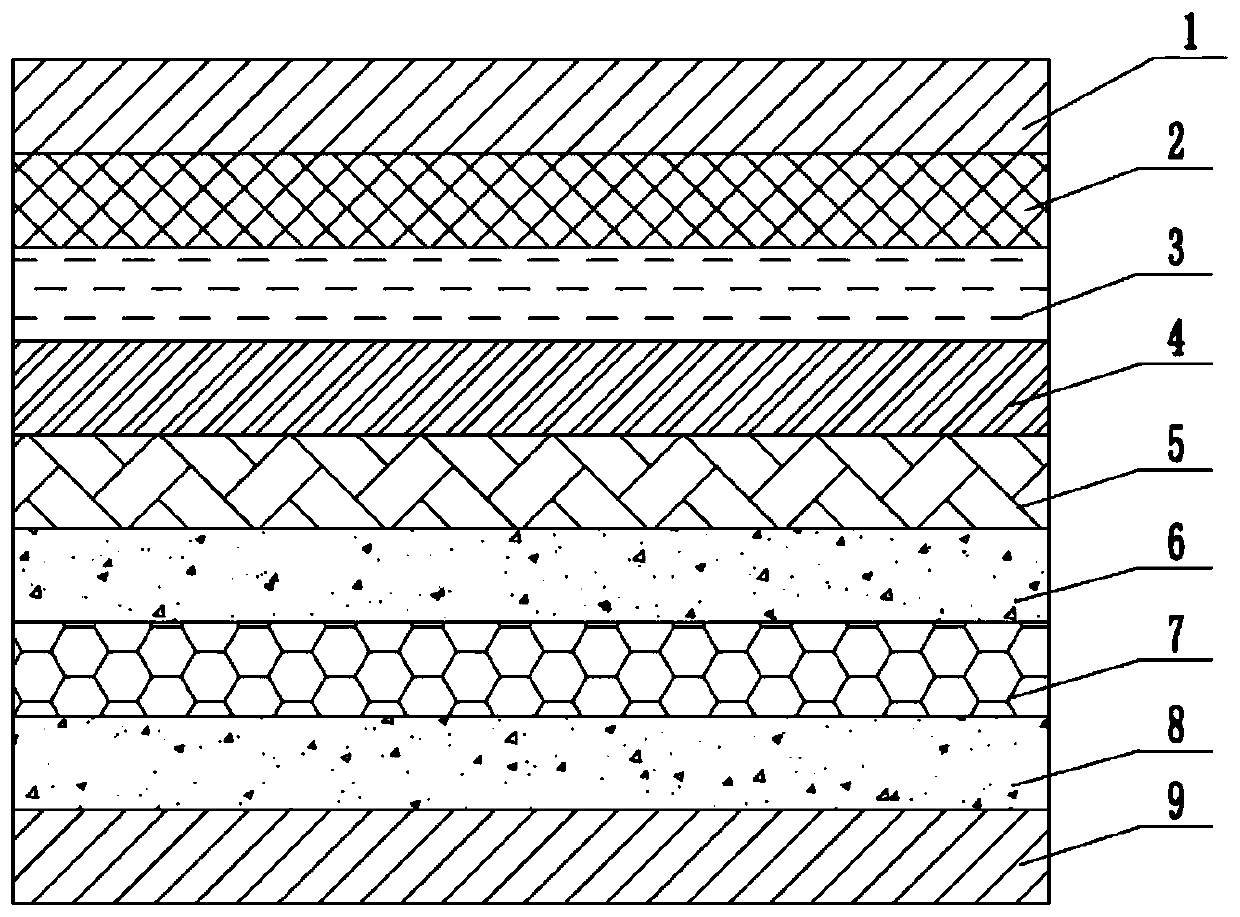

[0063] Such as figure 1 As shown, the point light source readable laser encryption holographic anti-counterfeiting gasket includes a PET layer 1, an imaging layer 2, a laser encryption information layer 3, an aluminum layer 4, a printing layer 5, and a gluing layer sequentially connected from top to bottom. The adhesive layer 6, the foam layer 7, the lower adhesive layer 8 and the lower PET layer 9 are sequentially connected, and the laser encryption information layer 2 hides digital coded information.

[0064] Described aluminized layer 4 thickness is

[0065] The foam layer 7 is PE foam with a thickness of 2mm.

[0066] The preparation method of the point light source reading laser encryption holographic anti-counterfeiting gasket includes the following steps:

[0067] (1) Use 20 μm PET film produced by DuPont, and coat the imaging layer on the corona surface of the PET film. The imaging layer and PET cannot be separated; the imaging layer formula: resin FL-7103B: 50kg, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com