Trolley automatic traveling method and system during converter tapping

A trolley and automatic technology, which is applied in the field of steelmaking methods and systems in the metallurgical industry, can solve the problems of undisclosed ladle trolleys automatically walking to the tapping position, etc., achieve good production and application prospects, accurate and reliable results, and simple and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The method and system for automatic traveling of trolleys in converter tapping according to the present invention will be further described according to the specific embodiments of the present invention and the accompanying drawings, but this description does not constitute an improper limitation of the present invention.

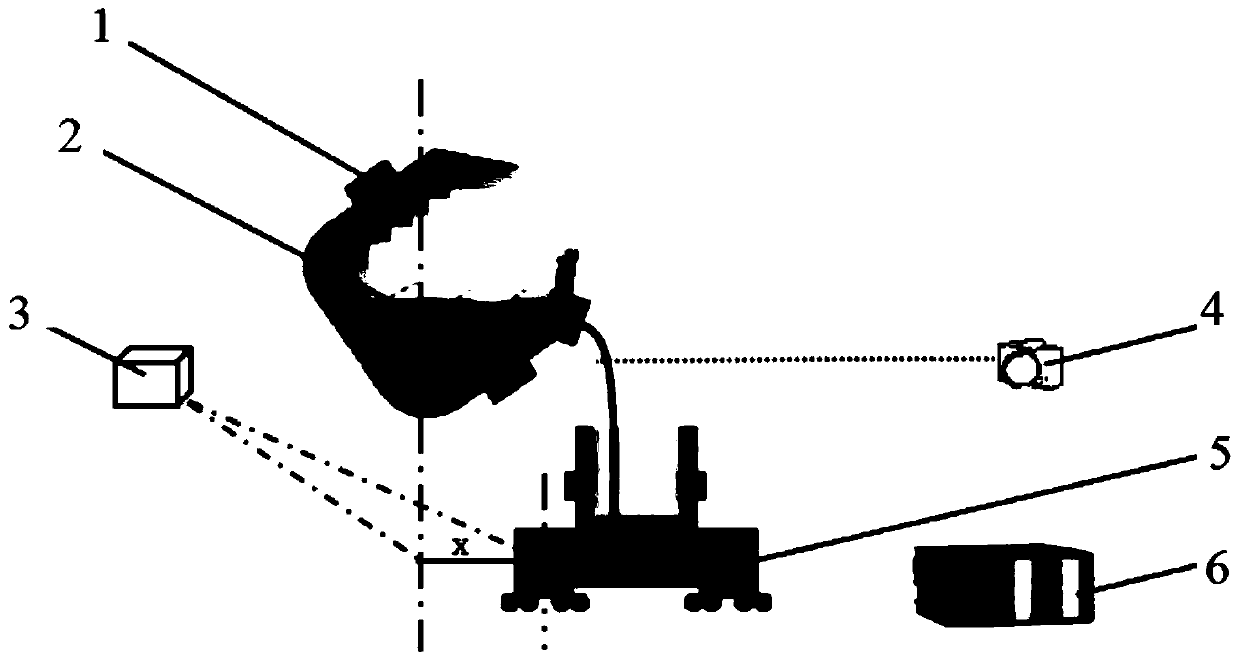

[0056] figure 1 It is a structural schematic diagram of an automatic running system of a trolley in converter tapping according to an embodiment of the present invention.

[0057] Such as figure 1 As shown, in this embodiment, when the molten steel 2 in the converter 1 is tapped, the image acquisition device 4 collects real-time images of the steel flow during the tapping process of the converter 1, and transmits the collected real-time image data to the computer system 6 , the non-contact ladle position detector 3 detects the distance x between the molten steel 2 and the ladle trolley 5 in real time, and transmits the detected distance data to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com