A railway track ballast burning type cleaning and maintenance equipment

A technology for railway track and maintenance equipment, which is applied in the direction of track, lighting and heating equipment, roads, etc. It can solve the problems of inability to screen and clean, affect railway safety, and high labor intensity, so as to protect the overall integrity and the safety of sleepers , the effect of protecting the movement route

Active Publication Date: 2022-06-03

四川钦耀炜岳建设工程有限公司

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Aiming at the deficiencies of the prior art, the present invention provides a railway track ballast burning type cleaning and maintenance equipment, which solves the problem of the existing railway ballast cleaning, which is labor intensive and can only be screened and cleaned on the main line of the railway. At the turnout, the operation is inconvenient, the screening and cleaning work cannot be carried out, and the process is cumbersome, which easily changes the ballast and affects the safety of the railway.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

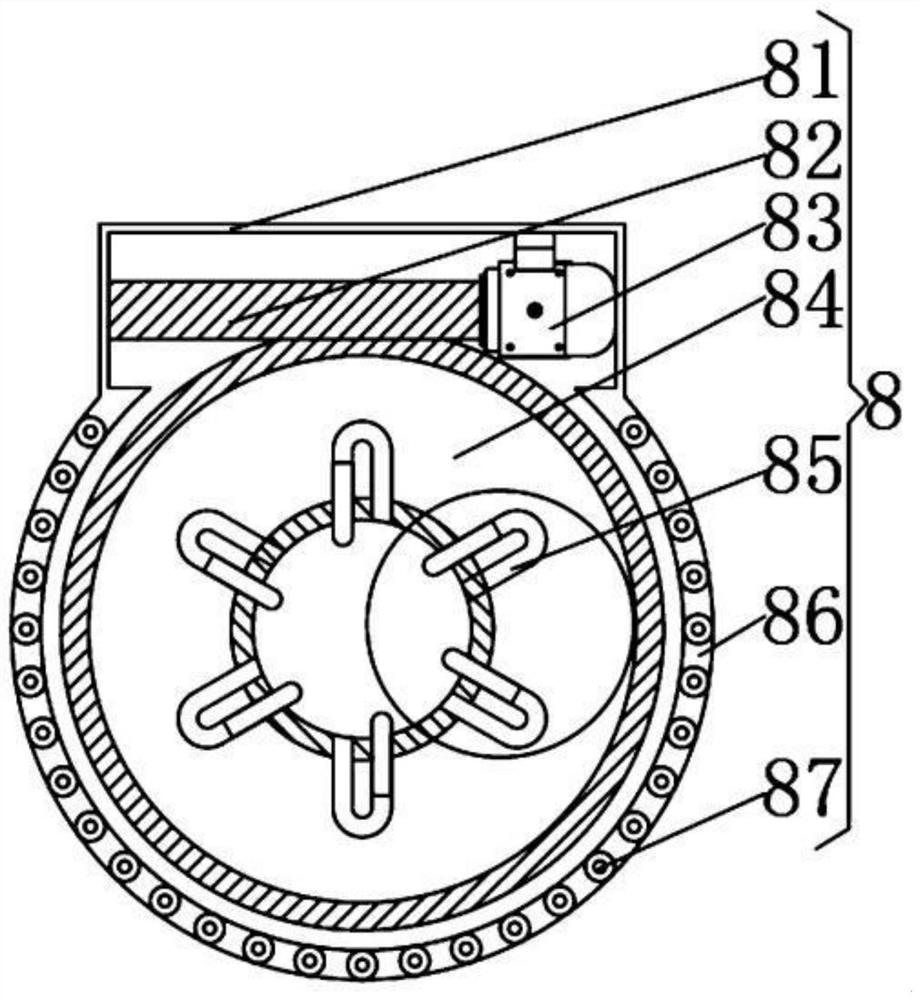

[0041] When gathering, the storage cylinder 12 is opened, and the fuel passes through the air hole 853 to exert pressure on the restricting plug 852, so that the restricting plug is

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

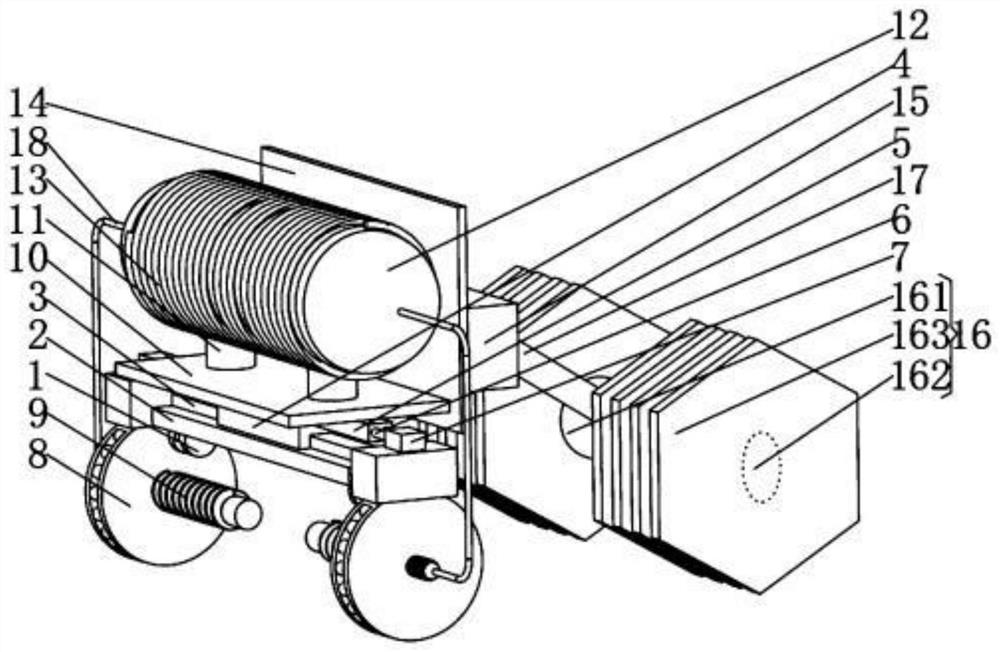

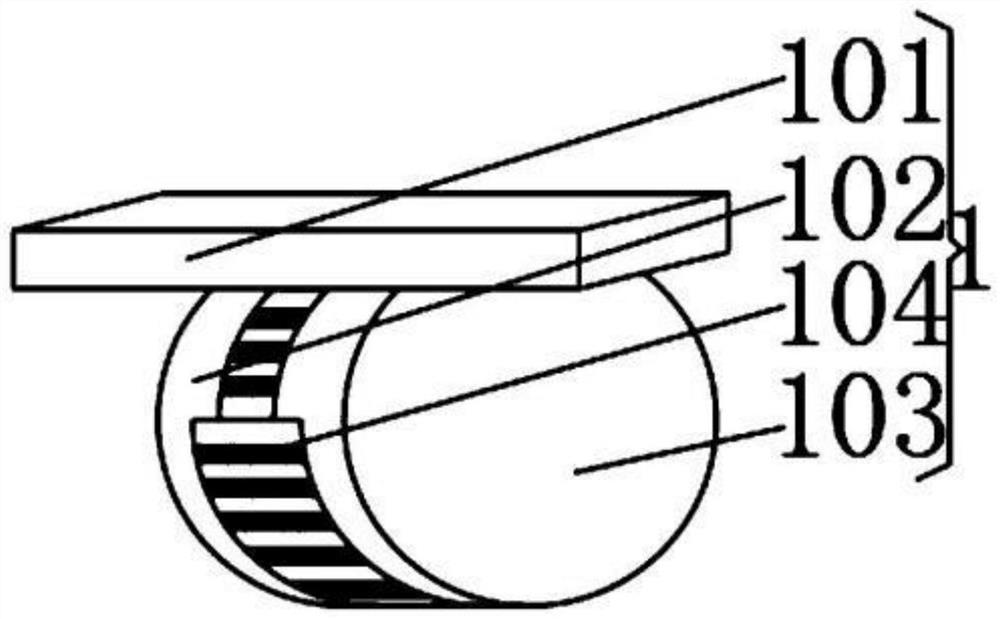

The invention discloses a railway track track slag burning type cleaning and maintenance equipment, which includes a positioning limiting wheel, and a permanent magnet track is fixedly connected to the middle position of the side of the fireproof heat shield far away from the positioning limiting wheel, and the permanent magnet track is far away from the One side of the fireproof heat insulation board is slidably connected with an electromagnetic sliding sleeve, and the middle position of the outer wall on both sides of the pneumatic telescopic cylinder is slidably connected with a telescopic column, and the bottom of the end block is fixedly connected with an adjustment mechanism, and the middle position of the adjustment mechanism is A burning and cleaning mechanism is threadedly connected, an induction heating mechanism is provided on the outer surface of the storage cylinder, and a pushing mechanism is movably connected to the side of the retracting mechanism away from the isolation baffle. The invention relates to the technical field of iron track slag cleaning. The equipment burns with open flame through fuel, rotates in an orderly manner, gathers and cleans ballast, evaporates the accumulated water, transfers heat to sleepers and rails through ballast heat conduction, and protects ballast and sleepers.

Description

A kind of railway track ballast slag burning cleaning and maintenance equipment technical field The present invention relates to the iron track slag cleaning technical field, be specially a kind of railway track ballast slag burning type cleaning and maintenance equipment. ready. Background technique At present, the roadbed of the railway is covered with ballast, and the effect of the ballast is to support the rails on the one hand, and to protect the rails on the other hand. roadbed. Since the ballast is exposed on the subgrade, a lot of water will accumulate in the ballast over time and penetrate into the subgrade, making the road The foundation becomes loose and soft, and problems such as pulping and subsidence occur, causing unsafe hazards to the operation of the train. Existing ballast cleaners The ballast slag screening machine is usually used for cleaning. When cleaning, the ballast slag should be scraped out from the bottom of the sleeper first, and then sc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01B27/00F26B23/02F23D14/66F23N5/26H05B6/06H05B6/10

CPCE01B27/00F26B23/02F23N5/26F23D14/66H05B6/10H05B6/06Y02E20/34

Inventor 韦海珍

Owner 四川钦耀炜岳建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com